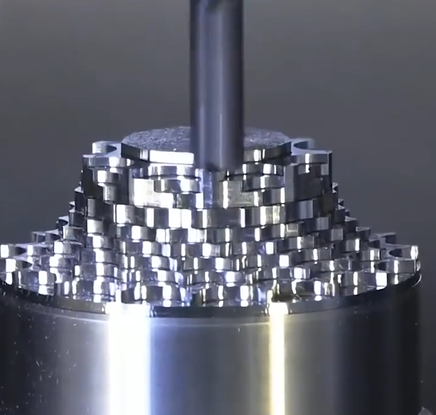

Molecular pump impellers are vital components in high-vacuum systems, demanding exceptional precision to ensure optimal performance and durability. Concentricity, defined as the alignment of the impeller’s rotational axis with its geometric center, is a critical quality factor that influences the pump’s efficiency and operational lifespan. Achieving high concentricity during machining, particularly through grinding, requires precise control of multiple parameters. This article provides a systematic, experience-based approach to optimizing grinding parameters to enhance concentricity in molecular pump impeller machining, emphasizing technical details, practical adjustments, and professional recommendations.

Fundamentals of Concentricity in Molecular Pump Impeller Machining

Concentricity measures the radial deviation between the impeller’s rotational axis and its geometric center, typically requiring tolerances of 0.002–0.005 mm for molecular pump impellers due to their high rotational speeds, often exceeding 30,000 RPM. Even slight deviations can lead to vibration, imbalance, or accelerated wear, compromising pump performance. Grinding, as the final machining stage, is critical for achieving these tight tolerances and ensuring a high-quality surface finish.

Several factors, including grinding wheel properties, machine setup, and process parameters, can introduce errors that affect concentricity. Proper parameter adjustment mitigates these issues, ensuring the impeller meets stringent specifications. The following sections outline key grinding parameters—wheel selection, feed rate, spindle speed, coolant application, and dressing frequency—and provide detailed guidance on their optimization to improve concentricity.

Critical Grinding Parameters for Concentricity Optimization

Effective concentricity control hinges on understanding and adjusting grinding parameters to minimize errors. Each parameter’s role and recommended settings are detailed below, based on practical experience and technical principles.

Grinding Wheel Characteristics

The grinding wheel is the primary tool for achieving precision, and its specifications directly impact concentricity. Molecular pump impellers, often made from titanium alloys or stainless steel, require wheels that balance material removal with surface integrity.

- Abrasive Material: Cubic Boron Nitride (CBN) wheels are preferred for their superior hardness and thermal stability, particularly for titanium alloys with low thermal conductivity. CBN wheels maintain consistent cutting performance, reducing uneven material removal.

- Grit Size: Use 120–180 grit for semi-finishing and 240–320 grit for finishing to achieve a surface roughness of Ra 0.2–0.4 µm, minimizing micro-irregularities that affect concentricity.

- Bond Type: Vitrified bonds provide rigidity and maintain wheel geometry, ensuring precise grinding. Resin bonds may be used for finishing to reduce vibration but require more frequent dressing.

- Wheel Hardness: Medium hardness (grade K–M) balances durability and self-sharpening, preventing excessive wear that could lead to inconsistent grinding forces.

Practical Adjustment: Choose a CBN wheel with a vitrified bond, 240 grit, and grade K for finishing titanium impellers. Balance the wheel to within 0.1 g·mm to eliminate spindle vibration, which can misalign the impeller’s axis.

Feed Rate and Depth of Cut

Feed rate and depth of cut govern material removal rate and grinding forces, both critical to concentricity. Excessive values can cause deflection, thermal distortion, or chatter, leading to axis misalignment.

- フィードレート: A feed rate of 0.01–0.02 mm/pass is recommended for finishing to minimize grinding forces. Lower rates reduce wheel loading, ensuring uniform material removal.

- カットの深さ: A shallow depth of 0.002–0.005 mm per pass is essential for precision grinding. Multiple light passes preserve impeller geometry and maintain concentricity.

Practical Adjustment: Set the feed rate to 0.015 mm/pass and depth of cut to 0.003 mm for finishing. Use force sensors, if available, to keep grinding forces below 50 N to prevent deflection.

Sp Wheel Speed

Spindle speed (workpiece rotation) and wheel speed (grinding wheel rotation) determine the cutting velocity, influencing surface quality and concentricity. Incorrect speeds can cause burn marks, vibration, or uneven wear.

- Wheel Speed: A wheel speed of 30–40 m/s is optimal for CBN wheels, ensuring efficient cutting without excessive heat buildup. Higher speeds may induce thermal expansion, misaligning the impeller.

- スピンドル回転数 A spindle speed of 100–200 RPM for the impeller ensures stable rotation and precise material removal. Lower speeds minimize centrifugal forces that could deform thin impeller blades.

Practical Adjustment: Set the wheel speed to 35 m/s and spindle speed to 150 RPM. Confirm spindle runout is below 0.001 mm to ensure rotational accuracy.

Coolant Application

Coolant manages grinding temperature and lubricates the cutting zone, preventing thermal distortion and wheel loading, which can degrade concentricity. チタン合金 require robust heat management due to their low thermal conductivity.

- Coolant Type: A water-based synthetic coolant with 5–10% concentration balances cooling and lubrication. Oil-based coolants may be used for ultra-precision grinding but require careful handling.

- Flow Rate: A flow rate of 20–30 L/min ensures effective cooling and chip removal. Direct the coolant jet at the grinding zone for maximum efficacy.

- Pressure: A pressure of 0.5–1.0 MPa prevents coolant vaporization in high-temperature zones.

Practical Adjustment: Use a 7% synthetic coolant at 25 L/min and 0.7 MPa, ensuring full coverage of the grinding zone. Monitor coolant pH (8–9) to prevent impeller corrosion.

Wheel Dressing Frequency and Technique

Wheel dressing maintains the wheel’s geometry and sharpness, directly affecting grinding accuracy. Inadequate dressing can lead to wheel glazing, causing uneven forces and concentricity errors.

- Dressing Frequency: Dress the wheel every 10–15 parts or after 30–40 minutes of continuous grinding to ensure consistency. Monitor surface finish for signs of glazing (e.g., increased Ra).

- Dressing Tool: A single-point diamond dresser with a tip radius of 0.1–0.2 mm offers precision. Rotary diamond dressers are suitable for complex wheel profiles.

- Dressing Parameters: Use a dressing depth of 0.01–0.02 mm and a traverse speed of 0.1–0.2 mm/rev to avoid over-dressing, which reduces wheel life.

Practical Adjustment: Dress the wheel every 12 parts using a single-point diamond dresser with a 0.015 mm depth and 0.15 mm/rev traverse speed. Inspect the wheel profile post-dressing for uniformity.

Systematic Optimization Process

A structured approach to parameter optimization ensures consistent concentricity. The following steps, grounded in industry experience, provide a reliable method for achieving and maintaining precision.

- Machine Calibration: Calibrate the grinding machine to ensure spindle runout is below 0.001 mm and table alignment is within 0.002 mm. Install a balanced CBN wheel and verify its concentricity.

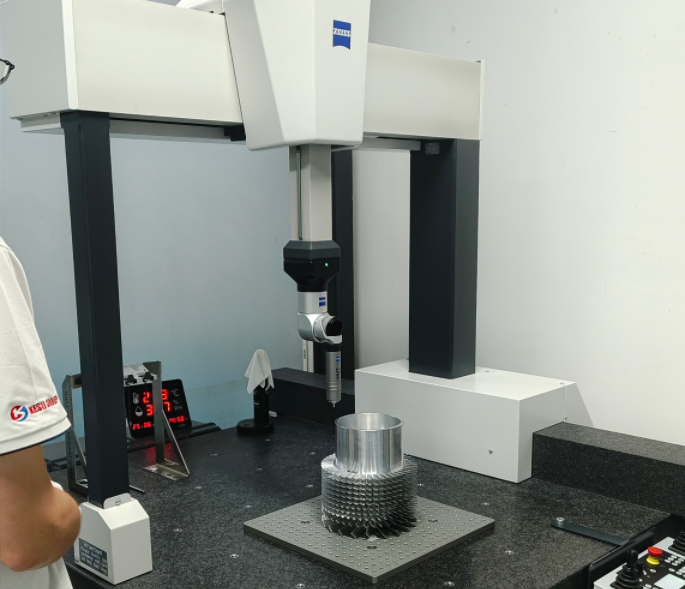

- Trial Grinding: Perform trial runs with conservative parameters (e.g., 0.02 mm/pass feed rate, 0.005 mm depth of cut) on a test impeller. Measure concentricity using a coordinate measuring machine (CMM) with 0.0001 mm resolution.

- Iterative Adjustments: Adjust one parameter at a time (e.g., reduce feed rate to 0.015 mm/pass) and re-measure concentricity. Use statistical process control (SPC) to track variations and ensure stability.

- Process Validation: Once concentricity reaches the target (e.g., 0.003 mm), validate the parameters across 10–20 parts to confirm repeatability. Monitor wheel wear and coolant condition.

- Ongoing Monitoring: Use in-process gauges or laser interferometry to monitor concentricity during production. Adjust dressing frequency or coolant flow based on real-time data.

Table: Recommended Grinding Parameters for Molecular Pump Impeller

| パラメータ | Recommended Value | 備考 |

|---|---|---|

| Grinding Wheel | CBN, 240 grit, vitrified bond, grade K | Balance to 0.1 g·mm |

| フィード・レート | 0.015 mm/pass | Keep forces < 50 N |

| 切り込み | 0.003 mm | Use multiple light passes |

| Wheel Speed | 35 m/s | Prevent thermal expansion |

| 主軸回転数 | 150 RPM | Runout < 0.001 mm |

| Coolant | 7% synthetic, 25 L/min, 0.7 MPa | Maintain pH 8–9 |

| Dressing Frequency | Every 12 parts | 0.015 mm depth |

Practical Implementation Considerations

While the recommended parameters provide a solid foundation, real-world grinding may encounter limitations that require specific adjustments. Below are key considerations to ensure consistent concentricity, addressing practical issues that may arise.

- Machine Rigidity: Verify that the grinding machine has adequate stiffness to resist deflection under grinding forces. Regular maintenance of bearings and slides prevents misalignment that could compromise concentricity.

- Operator Expertise: Ensure operators are trained to detect parameter drift, such as changes in surface finish or increased vibration, and to adjust settings promptly. Inconsistent practices can lead to variable concentricity outcomes.

- Material Variability: Account for batch-to-batch differences in impeller material properties (e.g., hardness or grain structure) by conducting pilot runs for new lots. Variations can alter grinding forces and wheel wear, affecting concentricity.

- Measurement Precision: Use high-precision CMMs or roundness testers calibrated to national standards for concentricity verification. Manual or uncalibrated gauges may introduce errors, leading to incorrect adjustments.

Table: Common Issues and Mitigation Strategies

| Issue | Impact on Concentricity | 緩和戦略 |

|---|---|---|

| Spindle Vibration | Axis misalignment | Balance wheel to 0.1 g·mm; check spindle runout |

| Thermal Distortion | Geometric errors | Use 7% coolant at 25 L/min, 0.7 MPa |

| Wheel Glazing | Uneven material removal | Dress every 12 parts with 0.015 mm depth |

| Material Variability | Inconsistent grinding forces | Conduct pilot runs for new material lots |

結論

Enhancing concentricity in molecular pump impeller machining demands precise control of grinding parameters, supported by a systematic approach and technical expertise. By optimizing grinding wheel selection, feed rate, depth of cut, spindle speed, coolant application, and dressing frequency, manufacturers can achieve concentricity tolerances as tight as 0.003 mm. The detailed parameters, systematic process, and practical considerations provided in this guide offer a reliable framework for professionals aiming to improve machining quality. Consistent monitoring, machine maintenance, and operator training further ensure process stability, delivering impellers that meet the rigorous demands of high-vacuum applications.