In mechanical machining, workpiece deformation is a frequent challenge that impacts production quality and leads to material waste. Addressing this issue requires a thorough understanding of its causes and the implementation of targeted solutions.

Influence of Material and Structure on Workpiece Deformation

The extent of deformation depends on several parameters:

- Shape Complexity: More intricate shapes increase deformation.

- Aspect Ratio: Higher length-to-width ratios amplify deformation risk.

- 壁厚: Thicker walls correlate with greater deformation.

- Material Rigidity and Stability: Less rigid or stable materials deform more easily.

Deformation is directly proportional to shape complexity, aspect ratio, and wall thickness, while inversely proportional to material rigidity and stability. During part design, minimizing these factors reduces deformation. For large parts, a rational structural design is critical. Pre-machining, the blank’s hardness (e.g., Rockwell scale) and porosity (e.g., defect percentage) must Showcasebe strictly controlled to ensure quality and limit deformation.

Deformation Due to Workpiece Clamping

Clamping introduces deformation if not managed properly. Key considerations include:

- Clamping Points: Should align with support points and be near the machining surface.

- Clamping Force: Must exceed cutting force (e.g., 500–1000 N depending on material) but avoid excess.

- Force Sequence: Apply contact force first (moderate, e.g., 300 N), then primary force last.

- Contact Area: Increase to distribute force (e.g., 50 cm² or more).

Clamping points should minimize deformation risk, with forces applied in a sequence: contact force first, not exceeding safe limits, followed by the main force to counter cutting. Enhancing rigidity via axial clamping or larger contact areas effectively mitigates this issue.

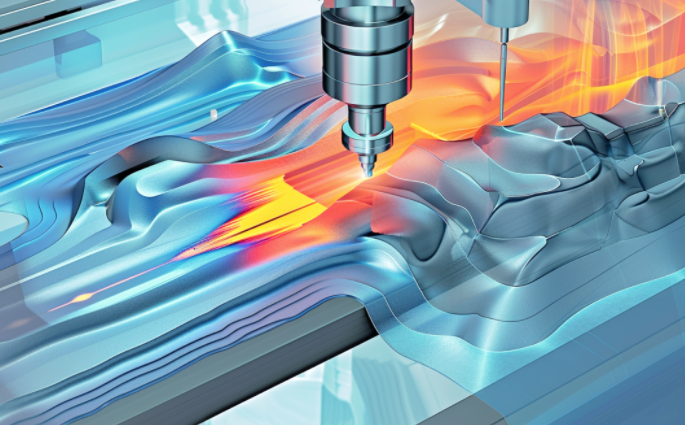

Deformation During Machining

Cutting forces cause elastic deformation, often called "tool yielding." Parameters include:

- Cutting Force: Varies by material (e.g., 200–800 N for steel).

- Tool Sharpness: Edge radius ideally below 0.02 mm for precision.

- Friction Resistance: Reduced by sharp tools.

- Heat Dissipation: Enhanced by tool design (e.g., coolant flow rate of 5 L/min).

Sharp tools reduce friction and improve heat dissipation, lowering residual stress (e.g., from 100 MPa to 50 MPa) and minimizing deformation during precision machining.

Post-Machining Stress Deformation

Internal stresses shift after material removal or heat treatment, altering shape. Solutions involve:

- Stack Height: Stack parts to 10–20 cm for stability.

- Fixture Pressure: Apply 100–300 N to straighten.

- Heating Temperature: 300–600°C based on material (e.g., steel vs. aluminum).

- Heating Time: 1–3 hours depending on thickness.

熱処理 stabilizes the internal structure precision machining, rebalancing stresses and maintaining shape post-processing.

Importance of Quality in Machining

Deformation impacts efficiency and cost:

- Scrap Rate: High rates (e.g., >10%) increase costs by 20–30%.

- Production Delay: Reduces output by hours daily.

Operators must monitor precision machining dynamics and apply professional knowledge to prevent deformation, safeguarding enterprise interests and customer satisfaction.

Factors Influencing Part Deformation

1 Internal Forces Affecting Accuracy

Clamping with three- or four-jaw chucks (force: 600–1200 N) stabilizes parts, but post-release, deviations (e.g., 0.1–0.5 mm) may result in polygonal or elliptical shapes.

2 Heat Treatment Deformation

Thin parts with high aspect ratios (e.g., 10:1) may exhibit "hat-bending" post-treatment, with deviations up to 1 mm due to stress shifts and operator error.

3 Elastic Deformation from External Forces

- Thin Sheets: Require precise machining positioning (tolerance ±0.05 mm).

- Fixture Unevenness: Causes 0.1–0.3 mm shifts.

- Poor Positioning: Reduces rigidity by 15–25%.

- Cutting Force: Induces elastic strain (e.g., 0.01–0.03%).

Improvement Measures for Deformation

Use specialized fixtures (e.g., custom jigs for 0.02 mm precision) and verify part precision machining positioning against drawings (tolerance ±0.01 mm) to minimize shifts. Pre-machining checks reduce clamping deformation by up to 50%.

結論

In actual part processing, there are many factors that cause part deformation. To fundamentally solve these deformation problems, operators need to carefully explore these factors in their actual work and formulate improvement measures by combining the essentials of the work. For different parts, selecting different special toolings can prevent the parts from displacement during the processing. In addition, before processing, staff also need to carry out corresponding preparatory work, comprehensively inspect the fixed parts, and check whether the positions of mechanical parts are correct against the drawings to reduce clamping deformation.