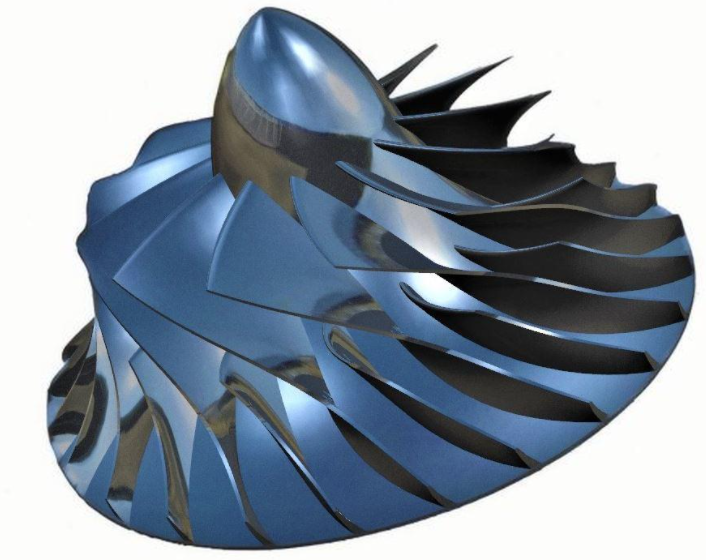

Precision casting is a critical manufacturing process for producing impellers, which are rotating components used in pumps, turbines, and compressors. These components require high dimensional accuracy, complex geometries, and excellent surface finish to ensure optimal performance under demanding conditions. This article explores the key precision casting techniques used for impeller production, focusing on investment casting, rapid prototyping, and advanced simulation, with detailed parameters and structured insights for industrial applications.

What Is Precision Casting for Impellers

Precision casting, particularly investment casting (also known as lost wax casting), is widely used for impeller production due to its ability to create intricate shapes with tight tolerances. Impellers often feature complex blade geometries, thin walls, and internal passages, making precision casting ideal. The process ensures minimal material waste, high repeatability, and compatibility with various alloys, including stainless steel, aluminum, and superalloys like Inconel. Other techniques, such as rapid prototyping and lost foam casting, complement traditional methods to enhance efficiency and reduce lead times.

Investment Casting Process for Impellers

Investment casting is the cornerstone of impeller production due to its precision and versatility. The process involves creating a wax pattern, coating it with a ceramic shell, removing the wax, and pouring molten metal into the mold. Below is a detailed breakdown of the investment casting process tailored for impellers:

| Step | 説明 | Key Parameters |

|---|---|---|

| Pattern Creation | Wax or plastic patterns are injected into a metal die to replicate the impeller's geometry. | Wax injection pressure: 20-50 bar; Die temperature: 20-30°C |

| Assembly | Multiple wax patterns are attached to a central wax sprue, forming a tree-like structure. | Sprue diameter: 10-20 mm; Pattern spacing: 5-10 mm |

| Shell Building | The wax assembly is dipped in ceramic slurry and coated with refractory sand, building a multi-layer shell. | Slurry viscosity: 20-30 seconds (Zahn cup); Drying time per layer: 4-6 hours |

| Dewaxing | The wax is melted out in an autoclave, leaving a hollow ceramic mold. | Autoclave temperature: 150-200°C; Pressure: 6-8 bar |

| Casting | Molten metal is poured into the preheated ceramic mold. | Pouring temperature: 1400-1600°C (stainless steel); Mold preheat: 900-1100°C |

| Shell Removal and Finishing | The ceramic shell is broken away, and the impeller undergoes cleaning, machining, and surface treatment. | Surface roughness: Ra 3.2-6.3 µm; Dimensional tolerance: ±0.05 mm |

Investment casting allows impellers to achieve dimensional tolerances as tight as ±0.05 mm and surface finishes of Ra 3.2 µm, reducing the need for extensive post-processing. The process is ideal for producing impellers with complex blade profiles, such as those used in aerospace turbines or industrial pumps, where high-performance alloys like Inconel 718 (tensile strength >1400 MPa after heat treatment) are common.

Rapid Prototyping in Impeller Casting

Rapid prototyping (RP) enhances impeller production by enabling faster pattern creation and design validation. Techniques like stereolithography (SLA), selective laser sintering (SLS), and material jetting produce high-accuracy wax or resin patterns directly from CAD models. These methods reduce lead times by up to 50% compared to traditional die-making, which can take weeks. Rapid investment casting (RIC) integrates RP with investment casting, offering flexibility for low-volume production or prototyping.

Key benefits of rapid prototyping include:

- Design Flexibility: Allows iterative design changes to optimize impeller blade geometry or detect casting defects early.

- コスト効率: Eliminates the need for expensive metal dies for small batches, with RP pattern costs ranging from $100-$500 per unit.

- Speed: Patterns can be produced in 1-3 days, compared to 2-4 weeks for traditional dies.

However, RP is less economical for high-volume production due to material costs, which can be 5-10 times higher than traditional wax. For impellers, RP is often used for initial design validation or to produce complex geometries, such as closed impellers for micro turbo-pumps, with accuracies within ±0.1 mm.

Advanced Simulation for Casting Optimization

Casting simulation software, such as MAGMASoft or ProCAST, optimizes impeller production by predicting mold filling, solidification, and defect formation. These tools use numerical methods to analyze thermal stresses, shrinkage porosities, and mechanical properties before casting begins. Simulation reduces pre-production sampling by up to 70%, saving material and tooling costs.

Key simulation parameters include:

- Mold Filling Analysis: Ensures complete cavity filling, with flow rates typically set at 0.5-2 kg/s for stainless steel impellers.

- Solidification Time: Controlled to minimize shrinkage, typically 10-30 seconds for small impellers (50-200 mm diameter).

- Thermal Stress Prediction: Identifies stress concentration areas, reducing defects like hot tears or cracks.

For example, simulation can predict shrinkage porosities in thick sections of an impeller hub, allowing engineers to adjust gating systems or add chills. A study on micro turbo-pump impellers demonstrated that simulation-guided casting achieved defect-free parts with dimensional accuracy within ±0.02 mm.

Materials for Impeller Casting

Material selection is critical for impeller performance, as it affects durability, corrosion resistance, and weight. The following table summarizes common materials used in impeller casting:

| 素材 | プロパティ | アプリケーション |

|---|---|---|

| ステンレス鋼 | High strength, corrosion resistance; tensile strength: 500-1000 MPa | Pump impellers, marine applications |

| アルミニウム合金 | Lightweight, corrosion-resistant; density: 2.7 g/cm³ | Automotive, industrial pumps |

| Inconel (e.g., 718) | High-temperature resistance, tensile strength: >1400 MPa (post-heat treatment) | Aerospace turbine impellers |

| チタン合金 | High strength-to-weight ratio, corrosion resistance; density: 4.5 g/cm³ | Medical, aerospace impellers |

Material choice depends on operating conditions. For instance, Inconel 718 is preferred for aerospace impellers due to its ability to withstand temperatures above 1000°C, while aluminum is used in lightweight automotive applications.

Challenges and Solutions in Impeller Casting

Precision casting of impellers faces challenges such as shrinkage porosities, incomplete mold filling, and surface defects. Solutions include:

- Vacuum or Low-Pressure Casting: Improves mold filling for thin-walled impellers, reducing oxidation and porosity.

- Advanced Binders: Silica-free binders, like aluminium-borophosphate, enhance mold strength and reduce defects in reactive alloys like titanium.

- Post-Processing: Heat treatment and electrical discharge machining (EDM) achieve accuracies within ±0.001 inches for critical features.

These solutions ensure high-quality impellers with minimal defects, meeting stringent industry standards.

結論

Precision casting techniques, particularly investment casting, rapid prototyping, and advanced simulation, are essential for producing high-performance impellers. These methods offer unmatched dimensional accuracy, material versatility, and the ability to create complex geometries. By leveraging simulation and rapid prototyping, manufacturers can optimize processes, reduce costs, and accelerate production. With proper material selection and defect mitigation strategies, precision casting ensures impellers meet the rigorous demands of aerospace, automotive, and industrial applications.