Titanium alloys are widely used in aerospace for manufacturing impellers due to their high strength-to-weight ratio, corrosion resistance, and thermal stability. However, high-speed cutting of titanium alloy impellers poses significant challenges to tool life due to rapid wear. This article provides a systematic approach to mitigating tool wear, focusing on material properties, tool selection, cutting parameters, and cooling strategies. The content is grounded in technical expertise and practical experience to ensure reliability and applicability in industrial settings.

Understanding Titanium Alloy Properties and Their Impact on Tool Wear

Titanium alloys, such as Ti-6Al-4V, exhibit unique properties that contribute to tool wear during high-speed cutting. These include low thermal conductivity, high chemical reactivity, and high strength at elevated temperatures. Low thermal conductivity (approximately 6.7 W/m·K, compared to 45 W/m·K for steel) causes heat to concentrate at the tool-chip interface, leading to temperatures exceeding 1000°C. High chemical reactivity results in adhesion between the tool and workpiece, promoting diffusion wear. Additionally, the high strength of titanium alloys increases cutting forces, accelerating abrasive wear.

Tool wear mechanisms in titanium machining include abrasive wear, adhesive wear, diffusion wear, and crater wear. Abrasive wear occurs due to hard inclusions in the alloy, while adhesive wear results from material sticking to the tool. Diffusion wear is driven by high temperatures, causing tool material atoms to migrate into the workpiece. Crater wear forms on the rake face due to combined thermal and chemical effects. Addressing these requires a comprehensive strategy tailored to titanium’s properties.

Selecting Appropriate Tool Materials

Tool material selection is critical for reducing wear in high-speed cutting of titanium alloy impellers. The ideal tool material should have high hardness, thermal stability, and low chemical affinity with titanium. Common materials and their characteristics are summarized below:

| 工具材料 | 硬度(HV) | Thermal Stability (°C) | メリット | 制限事項 |

|---|---|---|---|---|

| Carbide (WC-Co) | 1500–1800 | Up to 1200 | High toughness, cost-effective | Moderate wear at high speeds |

| Polycrystalline Diamond (PCD) | 7000–8000 | Up to 1300 | Excellent wear resistance, low friction | High cost, brittle |

| Cubic Boron Nitride (CBN) | 3000–4500 | Up to 1400 | High thermal stability, suitable for high speeds | Expensive, less effective for intermittent cutting |

| Ceramic (Al₂O₃-based) | 1800–2200 | Up to 2000 | High chemical stability | Low toughness, prone to chipping |

Carbide tools with fine-grained substrates and advanced coatings are commonly used due to their balance of toughness and cost. Coatings like TiAlN or AlCrN reduce friction and enhance thermal resistance, extending tool life by 20–40%. For ultra-high-speed applications, PCD or CBN tools are preferred, though their high cost restricts them to finishing operations. Tool geometry, such as a large rake angle (10°–15°) and sharp cutting edges, further minimizes wear by reducing cutting forces and heat generation.

Optimizing Cutting Parameters

Cutting parameters significantly influence tool wear in titanium alloy machining. The general principle is to use low cutting speeds, moderate feed rates, and sufficient depths of cut to balance productivity and tool life. Recommended parameters for high-speed cutting of titanium alloys are as follows:

| パラメータ | ラフティング | 仕上げ |

|---|---|---|

| 切削速度(m/min) | 30–60 | 20–40 |

| 送り速度(mm/rev) | 0.15–0.30 | 0.05–0.15 |

| 切り込み (mm) | 1.0–7.5 | 0.1–1.0 |

Low cutting speeds (30–60 m/min for roughing) minimize thermal load on the tool, as tool wear occurs rapidly above 100 m/min due to excessive heat. Moderate feed rates (0.15–0.3 mm/rev) ensure efficient chip formation without overloading the tool. Deeper cuts (1.0–7.5 mm) distribute heat over a larger area, reducing localized wear. For finishing, lower speeds and feeds improve surface quality and dimensional accuracy while preserving tool life. These parameters should be adjusted based on machine rigidity, tool condition, and impeller geometry.

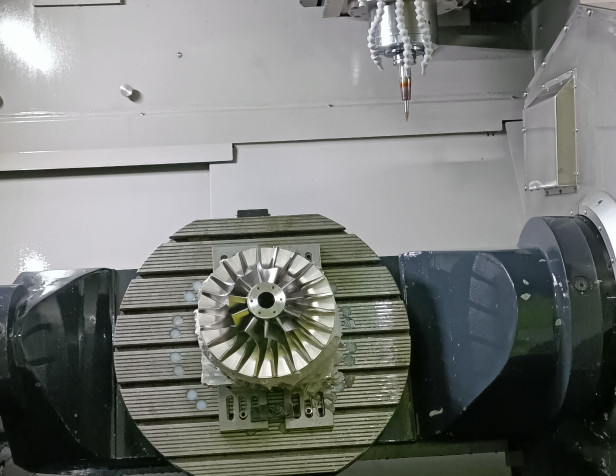

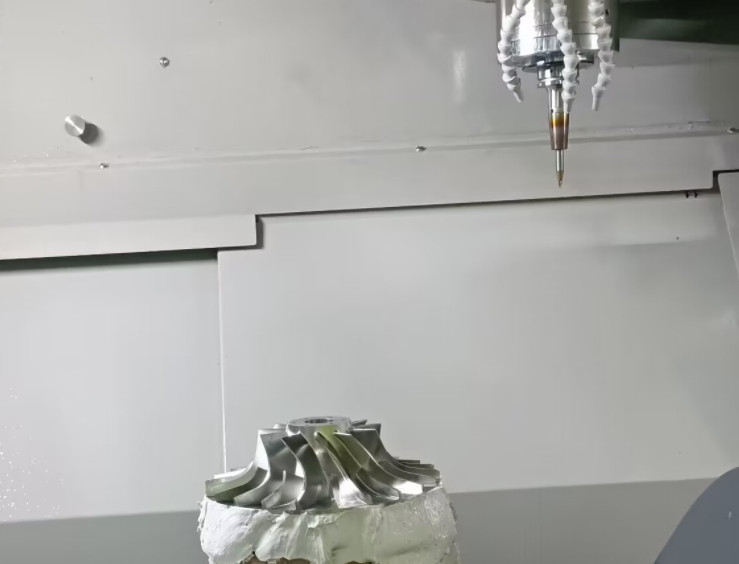

5軸加工 is often employed for impellers to maintain consistent cutting conditions and avoid tool overload. Using CAM software like HyperMill enables precise control of tool paths, minimizing sudden changes in cutting forces. Constant tool engagement angles (30°–50°) and smooth tool paths reduce vibration, which can exacerbate wear and cause tool chipping.

Implementing Effective Cooling and Lubrication

Cooling and lubrication are essential for managing heat and friction in titanium machining. Titanium’s low thermal conductivity makes it critical to remove heat from the cutting zone. Common cooling methods include flood cooling, high-pressure coolant, and minimum quantity lubrication (MQL).

Flood cooling delivers large volumes of coolant (10–20 L/min) to the tool-chip interface, reducing temperatures by 15–25%. However, its effectiveness diminishes at high speeds due to vapor barriers. High-pressure coolant (70–150 bar) penetrates the cutting zone more effectively, improving chip evacuation and cooling efficiency by up to 30%. It also reduces adhesion wear by minimizing tool-workpiece contact time. MQL uses a fine mist of oil and air at 0.05–0.5 L/h, offering environmental benefits and reducing friction by 15–20%. However, MQL is less effective for heavy-duty roughing due to limited cooling capacity.

Coolant composition is equally important. Water-based emulsions with 5–15% concentration are standard, containing additives like sulfur or phosphorus to enhance lubricity. For high-pressure applications, synthetic oils with high thermal stability are preferred. Coolant nozzles should be positioned to target the rake face and flank face simultaneously, ensuring consistent delivery to the cutting edges.

Tool Design and Maintenance Practices

Customized tool designs and rigorous maintenance practices are crucial for minimizing wear. Tools should feature reinforced edges, such as those treated with sandblasting or honing, to resist chipping. U-shaped chip grooves improve chip flow, reducing friction and heat buildup. Coating thickness (2–5 µm) and uniformity are critical to prevent peeling under high temperatures and stresses.

Regular tool inspection is necessary to detect early signs of wear, such as flank wear width >0.3 mm or crater depth >0.1 mm). Using optical or digital microscopes ensures accurate assessment. Tools should be reconditioned promptly through regrinding or recoating to restore edge geometry and coating properties. Maintaining machine tools, such as ensuring spindle runout <20 μm, prevents vibration-induced wear. Clamping systems must be rigid to minimize deflection, with tool overhangs kept below 3–4 times the tool diameter.

Case Study: Practical Implementation

In a real-world example, a manufacturer machining a Ti-6Al-4V impeller (150 mm diameter) using a five-axis CNC machine reduced tool wear by 25% through the following measures:

- Tool: Carbide with TiAlN coating, 12 mm diameter, 12° rake angle.

- Parameters: Cutting speed 40 m/min, feed rate 0.2 mm/rev, depth of cut 2 mm.

- Cooling: High-pressure coolant at 80 bar, 15 L/min.

- Tool Path: HyperMill-generated paths with 40° engagement angle.

Regular inspection after 20 minutes of cutting ensured timely tool replacement, maintaining surface roughness Ra ≤ 1.6 μm. These adjustments extended tool life from 45 to 60 minutes per cycle, improving productivity.

結論

Mitigating tool wear in high-speed cutting of titanium alloy impellers requires an integrated approach encompassing tool material selection, optimized cutting parameters, effective cooling, and robust tool design. By understanding titanium’s properties and tailoring machining processes accordingly, manufacturers can achieve consistent tool life, improved surface quality, and cost efficiency. The strategies outlined—carbide or PCD tools, low-speed parameters, high-pressure cooling, and customized tool designs—provide a reliable framework for industrial applications. Regular maintenance and precise process control further enhance outcomes, as demonstrated in practical case studies.