Optimize your CNC machining process with these expert tips to enhance efficiency, reduce costs, and ensure high-quality results. Whether you're designing parts, selecting materials, or planning production, avoiding common mistakes is key to achieving precision and cost-effectiveness. This guide outlines eight critical areas—design, materials, processes, operations, quality, communication, cost control, and safety—to help you streamline your workflow and deliver superior machined components.

1. Design Phase Pitfalls

Avoid Overly Complex Designs

Issue: Complex features like irregular holes, non-standard threads, or internal right angles can make machining impossible or costly.

Solution: Opt for standardized structures (e.g., rounded corners instead of right angles), simplify non-essential features, and confirm feasibility with the machining team early.

Focus on Material Removal Rate

Issue: Ignoring machining allowances can lead to prolonged processing times or material waste.

Solution: Ensure sufficient machining allowances (0.5-2mm for roughing, 0.1-0.5mm for finishing) to prevent part rejection due to insufficient 材料.

Reasonable Tolerance Specification

Issue: Over-specifying tolerances (e.g., ±0.01mm) increases machining difficulty and costs.

Solution: Specify tolerances based on functional needs, relaxing requirements for non-critical dimensions.

Thin-Wall Parts and Deformation Control

Issue: Thin-walled structures are prone to deformation during machining.

Solution: Add reinforcing ribs and process in stages (roughing, stress relief, then finishing).

2. Material Selection Pitfalls

Avoid Hard-to-Machine Materials

Issue: Materials like stainless steel or titanium alloys have poor machinability, causing rapid tool wear.

Solution: Choose easier-to-machine materials like aluminum alloys or 45# steel unless high hardness is required.

Consider Material Heat Treatment

Issue: Non-annealed materials are harder, increasing machining difficulty.

Solution: Verify material condition and perform heat treatment before machining if necessary.

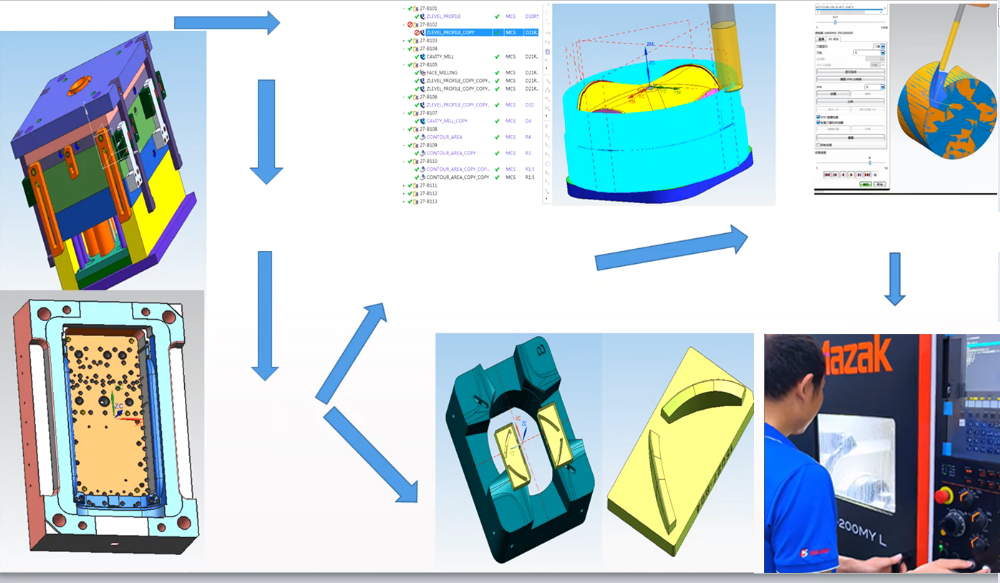

3. Process Planning Pitfalls

Incorrect Process Sequencing

Issue: Machining fine features before roughing can cause deformation or damage.

Solution: Follow the sequence: roughing → semi-finishing → finishing, starting with datum surfaces.

Unreasonable Cutting Parameters

Issue: High speeds or feeds cause tool breakage, while low settings reduce efficiency.

Solution: Use tool manufacturer’s recommended parameters, adjusted for material properties.

Neglecting Fixture Design

Issue: Unstable clamping leads to machining offsets or vibrations.

Solution: Use dedicated fixtures for complex parts to ensure even force distribution.

4. Machining Operation Pitfalls

Improper Tool Selection

Issue: Using finishing tools for roughing shortens tool life.

Solution: Use large-diameter, low-precision tools for roughing and high-precision coated tools for finishing.

Improper Coolant Use

Issue: Dry cutting overheats tools, and insufficient coolant concentration reduces effectiveness.

Solution: Use ample coolant for high-hardness materials and regularly check coolant concentration.

Ignoring Machine Calibration

Issue: Spindle runout or guide rail errors lead to inaccurate machining.

Solution: Regularly calibrate machines with a dial indicator and run programs dry before machining.

5. Quality Inspection Pitfalls

Skipping First Article Inspection

Issue: Bypassing first article inspection risks batch failures.

Solution: Implement strict first article inspections (self, peer, and specialized checks).

Measurement Tool Errors

Issue: Uncalibrated calipers or micrometers produce unreliable results.

Solution: Regularly calibrate tools and use CMM for critical dimensions.

6. Communication and Collaboration Pitfalls

Incomplete Drawings

Issue: Missing details like surface roughness or chamfers lead to unexpected results.

Solution: Provide complete drawings with material, heat treatment, and surface finish requirements.

Unclear Delivery Standards

Issue: Assuming machinists understand all requirements leads to rework.

Solution: Confirm acceptance criteria in writing, including burr handling and packaging.

7. Cost Control Pitfalls

Overemphasizing Unit Cost

Issue: Choosing complex processes to save material increases overall costs.

Solution: Evaluate material, labor, and tool wear costs to find the optimal approach.

Ignoring Batch Optimization

Issue: Using large-batch processes for small runs reduces efficiency.

Solution: Use universal fixtures for small batches and dedicate tools for large batches.

8. Safety and Maintenance Pitfalls

Neglecting Equipment Maintenance

Issue: Failing to clean chips or lubricate guide rails reduces machine accuracy.

Solution: Clean machines daily and perform periodic maintenance per the manual.

Unsafe Operations

Issue: Operating rotating equipment with gloves or starting without secure clamping poses risks.

Solution: Follow safety protocols, wear proper PPE, and confirm secure clamping before starting.

Key Takeaways for CNC Machining Success

- Design for Manufacturability: Simplify structures and avoid unnecessary precision.

- Process Alignment: Choose processes that match project needs, not just the most advanced options.

- Attention to Detail: Every step, from tool selection to measurement, impacts quality.

- Clear Communication: Align with machinists to avoid assumptions and ensure expectations are met.