Impellers are essential components in centrifugal pumps, responsible for transferring energy to fluids, increasing their pressure and flow. The impeller’s design directly impacts pump efficiency, flow rate, head pressure, and suitability for specific fluids. This article explores the primary impeller types—open, semi-open, closed, recessed (vortex), screw, and cutter—detailing their characteristics, applications, and performance parameters to guide engineers and industry professionals in selecting the optimal design.

Impeller Functionality and Importance

An impeller is a rotating component with vanes that imparts kinetic energy to a fluid, creating centrifugal force to drive it outward. Fluid enters through the impeller’s central eye and is accelerated by the vanes, exiting via a volute or nozzle. The impeller’s design influences flow patterns (axial, radial, or mixed), efficiency, and compatibility with fluids containing solids, high viscosity, or corrosive properties. Factors such as fluid characteristics, flow rate, head, and operational conditions dictate the choice of impeller type.

Main Types of Impellers

Impellers are categorized based on their structural design and flow characteristics. The following sections detail the six primary types: open, semi-open, closed, recessed (vortex), screw, and cutter impellers. Each is tailored for specific applications, balancing efficiency, durability, and maintenance needs.

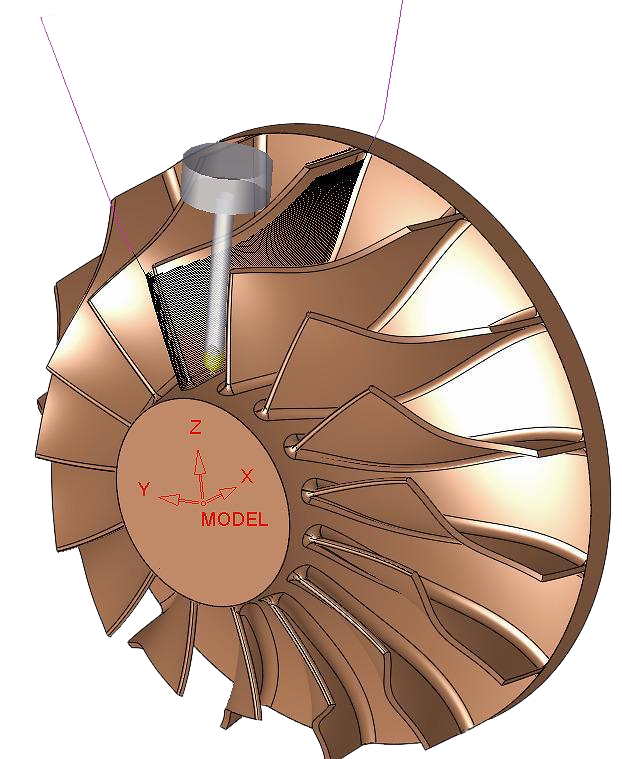

Open Impellers

Open impellers feature vanes directly connected to a central hub without front or back shrouds, exposing the blades to the fluid. This open design provides ample space for handling large particles and medium-to-high-viscosity fluids, reducing the risk of clogging. However, the lack of shrouds results in lower structural integrity and efficiency due to fluid bypass around the vanes.

- Characteristics: No shrouds, exposed vanes, high NPSH requirements.

- メリット: Simple structure, low manufacturing cost, clog-resistant, suitable for fluids with suspended solids.

- デメリット: Low efficiency (typically 40-60%), structurally weaker, prone to cavitation.

- アプリケーション: Mining slurry, sewage, mud, wastewater treatment, food industry.

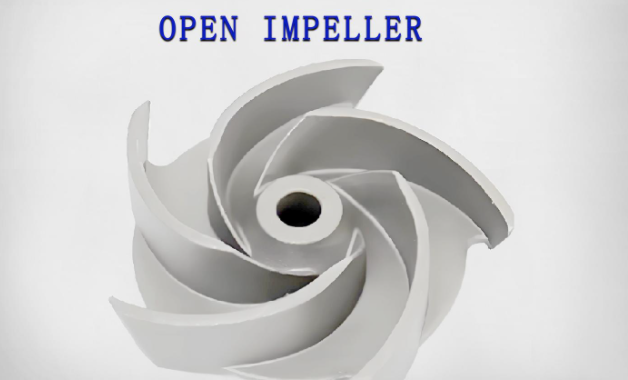

Semi-Open Impellers

Semi-open impellers have vanes attached to a single back shroud, with the other side exposed to the fluid. This design offers a balance between open and closed impellers, providing moderate efficiency and the ability to handle fluids with small amounts of suspended solids. A small clearance between the vanes and pump casing is critical to minimize fluid recirculation, and axial adjustments can compensate for wear.

- Characteristics: Single shroud, moderate efficiency (50-70%), adjustable clearance.

- メリット: Clog-resistant, stronger than open impellers, handles small solids and viscous fluids.

- デメリット: Lower efficiency than closed impellers, sensitive to clearance changes, potential fluid recirculation.

- アプリケーション: Petrochemicals, wastewater treatment, mining, food processing.

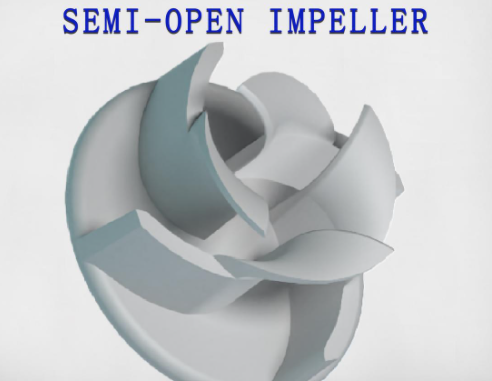

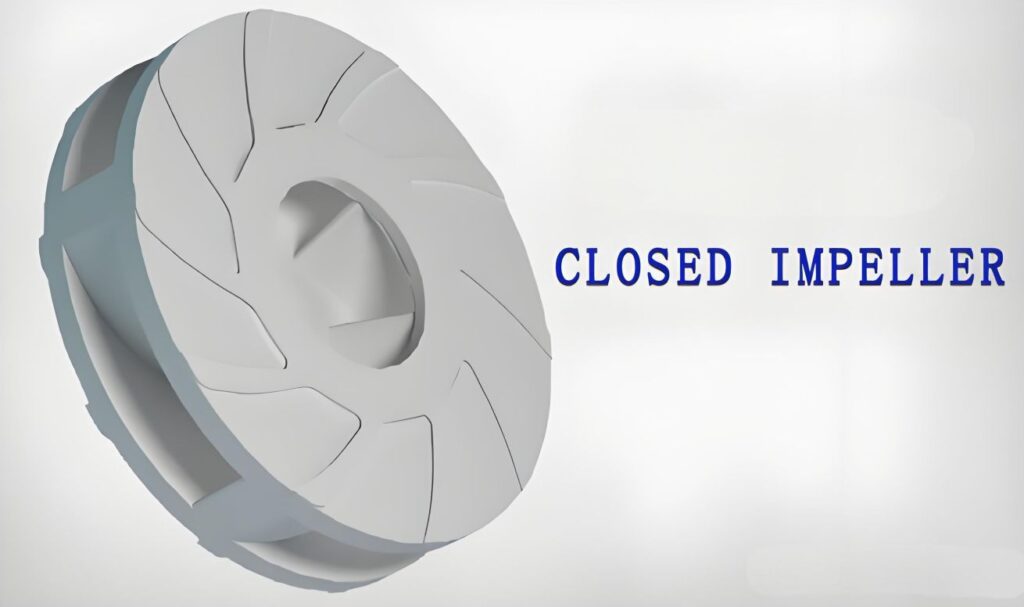

Closed Impellers

Closed impellers feature vanes enclosed between two shrouds, forming sealed flow channels that maximize efficiency and structural strength. They rely on close-clearance wear rings to prevent fluid recirculation, making them ideal for clean liquids and high-pressure applications. Their complex design increases manufacturing and maintenance costs but ensures low NPSH requirements.

- Characteristics: Dual shrouds, high efficiency (70-85%), robust design.

- メリット: High efficiency, low NPSH, suitable for high-pressure and clean fluids.

- デメリット: Higher manufacturing cost, difficult to clean, prone to clogging with solids.

- アプリケーション: Petrochemicals, mining, dredging, shield tunneling, wastewater treatment.

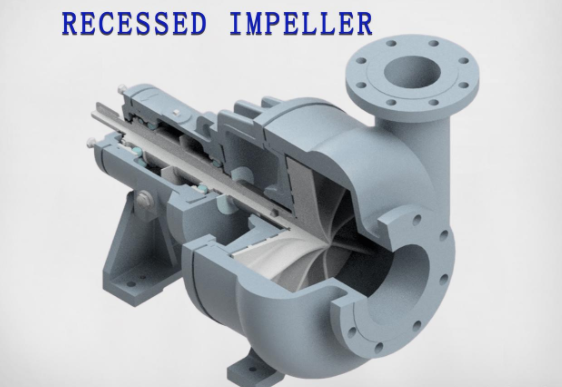

Recessed (Vortex) Impellers

Recessed impellers, also known as vortex impellers, have vanes partially recessed into the pump body, creating a vortex effect that moves fluid without direct vane contact. This design minimizes wear and clogging, making it suitable for fluids with large particles, long fibers, or gas content. However, the vortex effect results in lower efficiency due to energy losses.

- Characteristics: Recessed vanes, vortex-driven flow, efficiency typically 30-50%.

- メリット: Clog-resistant, low wear, long lifespan, handles large particles and fibrous fluids.

- デメリット: Low efficiency, unsuitable for high-head or high-pressure conditions.

- アプリケーション: Sewage treatment, mining slurry, paper industry, chemical processing, oil and gas.

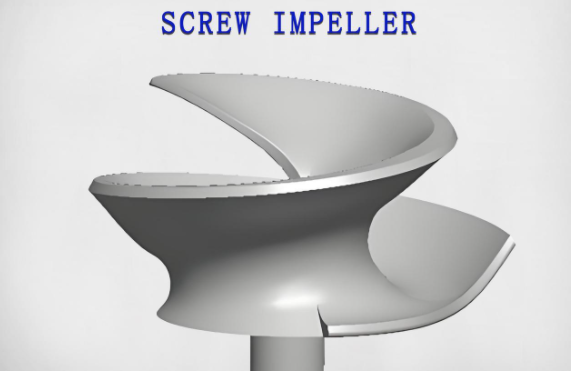

Screw Impellers

Screw impellers feature a screw-like channel design, resembling a propeller, that enables stable axial flow and the passage of large solids without clogging. They are highly efficient for thick, viscous liquids or slurries, commonly used in applications requiring robust handling of challenging fluids.

- Characteristics: Screw-shaped channels, axial flow, efficiency 60-75%.

- メリット: Clog-resistant, handles high-viscosity fluids and large solids, stable flow.

- デメリット: High manufacturing cost, low head and pressure output.

- アプリケーション: Petrochemicals, food processing, pharmaceuticals, marine, mining.

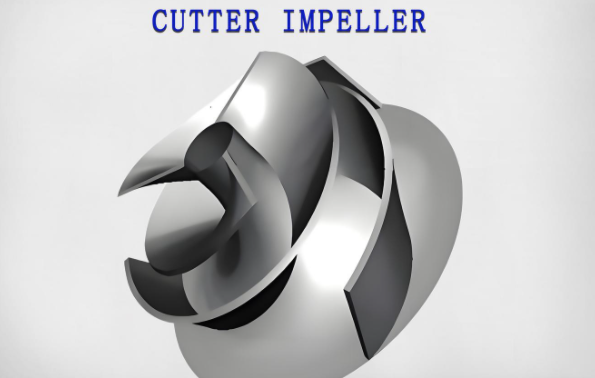

Cutter Impellers

Cutter impellers, also known as chopper impellers, incorporate cutting mechanisms to break down large solids or long fibers in the fluid before pumping. This design prevents blockages and reduces maintenance frequency, making it ideal for heavy-duty applications involving solid-laden fluids.

- Characteristics: Integrated cutting mechanism, moderate efficiency (50-65%).

- メリット: Clog-resistant, processes large solids and fibers, reduces maintenance.

- デメリット: Higher power consumption, faster vane wear, complex design.

- アプリケーション: Municipal sewage, food waste, livestock wastewater, industrial waste processing.

Impeller Flow Patterns

Impellers generate three primary flow patterns—axial, radial, and mixed—each suited to specific applications based on flow rate and head requirements.

| Flow Pattern | 説明 | アプリケーション |

|---|---|---|

| Axial | Fluid flows parallel to the impeller shaft, producing high flow rates with low head. | Low-viscosity blending, solids suspension, heat transfer. |

| Radial | Fluid flows perpendicular to the shaft, generating high head with lower flow rates. | Gas-liquid dispersion, high-pressure applications. |

| Mixed | Combines axial and radial flow, balancing flow rate and head. | General-purpose pumps, versatile applications. |

Key Parameters Affecting Impeller Performance

Impeller performance depends on several design and operational parameters, which must be optimized to meet specific application needs.

| パラメータ | 説明 | Impact |

|---|---|---|

| Impeller Diameter | Outer diameter, typically 100-500 mm. | Larger diameters increase head and flow but raise energy consumption (H ∝ D²). |

| Blade Angle | Inlet (β₁) and outlet (β₂) angles, typically 15°-45°. | Optimizes fluid entry/exit, reduces turbulence, enhances efficiency. |

| Number of Blades | Typically 4-12 blades. | More blades improve efficiency but increase manufacturing complexity. |

| Blade Shape | Curved, straight, or radial element blades. | Curved blades reduce turbulence, improve flow guidance. |

| 素材 | Stainless steel, cast iron, alloys, or nonmetallics. | Affects durability, corrosion resistance, and fluid compatibility. |

Selecting the Right Impeller

Choosing the appropriate impeller requires evaluating fluid properties (viscosity, solids content, corrosiveness), desired flow rate, head pressure, and operational conditions. Open impellers are ideal for fluids with large solids, while closed impellers suit clean, high-pressure applications. Recessed (vortex) impellers excel in handling debris-laden fluids, and screw or cutter impellers manage viscous or solid-heavy fluids. Simulation tools like SimScale or CFturbo can aid in optimizing impeller selection by analyzing flow behavior and performance metrics.

結論

Impellers are critical to centrifugal pump performance, with each type—open, semi-open, closed, recessed (vortex), screw, and cutter—offering unique advantages for specific applications. By understanding their characteristics, flow patterns, and performance parameters, engineers can select the optimal impeller to achieve high efficiency, reliability, and minimal maintenance. Proper impeller selection ensures robust performance across industries like petrochemicals, wastewater treatment, mining, and food processing.