Closed impellers are a critical component in high-speed rotating devices, such as centrifugal pumps and compressors, due to their ability to meet demanding performance and reliability requirements. This article provides a detailed technical analysis of why closed impellers are preferred in these applications, focusing on their design, efficiency, structural integrity, and operational characteristics. The discussion emphasizes technical precision and avoids speculative trends, offering a systematic exploration of the factors driving their widespread use.

Understanding Impeller Types and Their Applications

Impellers are rotating components in centrifugal pumps and compressors that transfer energy from a motor to a fluid, increasing its velocity and pressure. The primary types of impellers include open, semi-open, and closed designs, each suited to specific applications based on fluid properties and operational conditions.

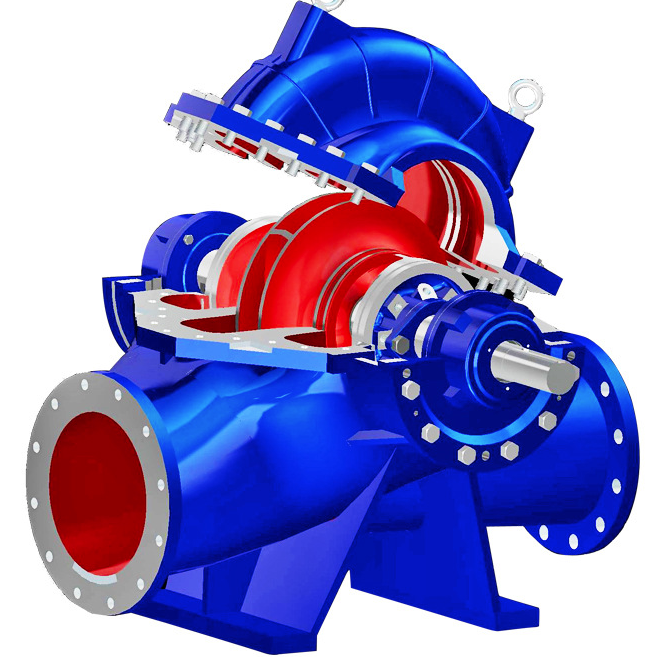

An open impeller consists of vanes attached to a central hub without any shroud or cover, making it suitable for low-viscosity fluids with minimal solids. Semi-open impellers feature a single shroud on one side, offering a balance between strength and ease of maintenance. Closed impellers, however, are fully enclosed with shrouds on both the front and back of the vanes, providing maximum structural integrity. The closed design is prevalent in high-speed rotating devices due to its ability to handle high-pressure and high-velocity conditions effectively.

The choice of impeller type depends on factors such as fluid viscosity, solids content, flow rate, and rotational speed. Closed impellers are particularly favored in high-speed applications, such as large centrifugal pumps and compressors, where reliability and efficiency are paramount.

Structural Advantages of Closed Impellers

Closed impellers are designed with two solid plates (shrouds) attached to both sides of the vanes, creating a robust structure that can withstand the significant centrifugal forces encountered at high rotational speeds. This design minimizes vane deflection and reduces stress concentrations, which are critical in high-speed environments where speeds often exceed 4000 rpm.

The shrouds enhance the impeller’s mechanical strength, allowing it to operate under high-pressure conditions without deformation. For example, in centrifugal pumps, closed impellers can handle discharge pressures ranging from 10,000 to 20,000 kPa in multistage configurations. The enclosed design also reduces the risk of vane fatigue failure, which is a common issue in open impellers due to their lack of structural support.

Additionally, the closed impeller’s design reduces axial thrust loads on the pump shaft. By enclosing the fluid between the shrouds, the impeller minimizes pressure imbalances that could lead to excessive thrust, thereby extending bearing life. This is particularly important in high-speed applications, where bearing reliability directly impacts system performance.

The table below summarizes the structural differences between impeller types:

| Impeller Type | Structural Features | Typical Speed Range (rpm) | Pressure Range (kPa) |

|---|---|---|---|

| Open | Vanes without shrouds | 1000–3000 | 1000–5000 |

| Semi-Open | Vanes with one shroud | 2000–4000 | 5000–10,000 |

| Closed | Vanes with two shrouds | 4000–10,000 | 10,000–20,000 |

Hydraulic Efficiency and Performance

Closed impellers are highly efficient in converting mechanical energy into hydraulic energy due to their enclosed flow passages. The shrouds create a controlled flow path, reducing internal recirculation and turbulence losses. This results in higher hydraulic efficiency compared to open or semi-open impellers, typically achieving efficiencies of 85–90% in well-designed systems.

The efficiency of a closed impeller is governed by Bernoulli’s equation, which describes energy conservation in fluid flow:

P + ½ρv² + ρgh = constant

Here, P is the pressure, ρ is the fluid density, v is the velocity, g is the gravitational acceleration, and h is the elevation. In closed impellers, the enclosed vanes ensure that the fluid’s velocity is maximized as it moves radially outward, increasing the pressure at the discharge. This is particularly effective in high-speed applications, where the impeller’s rotational speed (often 4000–8000 rpm) generates significant centrifugal force.

Another critical factor is the Euler turbomachinery equation, which relates the change in fluid energy to the impeller’s geometry and rotational speed:

ΔH = (U₂Vᵤ₂ – U₁Vᵤ₁)/g

In this equation, ΔH is the change in total head, U is the impeller’s tangential velocity, and Vᵤ is the tangential component of the fluid’s absolute velocity at the inlet (1) and outlet (2). Closed impellers optimize the transfer of energy by maintaining a consistent flow path, reducing slip and ensuring that the fluid exits at the desired velocity and pressure.

Closed impellers also have a lower Net Positive Suction Head (NPSH) requirement, typically 2–3 meters compared to 4–6 meters for open impellers. This makes them suitable for applications with limited suction pressure, reducing the risk of cavitation, which can damage the impeller and reduce performance.

Operational Stability at High Speeds

High-speed rotating devices, such as centrifugal compressors and pumps, operate at speeds ranging from 4000 to 10,000 rpm or higher, depending on the application. Closed impellers provide superior operational stability due to their balanced design and reduced sensitivity to clearance variations. The shrouds maintain close tolerances with the pump casing, typically 0.1–0.5 mm, ensuring minimal fluid leakage back to the suction side.

This close clearance is achieved through wear rings, which are replaceable components that maintain efficiency by preventing recirculation. While wear ring clearance increases over time (e.g., from 0.2 mm to 0.5 mm after prolonged use), closed impellers are less sensitive to this wear compared to open impellers, which rely on tight vane-casing tolerances. For example, a 0.3 mm increase in clearance in an open impeller can reduce efficiency by 5–10%, whereas closed impellers typically experience a 2–3% efficiency loss under similar conditions.

The stability of closed impellers is further enhanced by their ability to operate across a wide range of specific speeds (Ns), typically 500–3000, making them versatile for various flow and head requirements. Specific speed is defined as:

Ns = N√Q / H^(3/4)

where N is the rotational speed (rpm), Q is the flow rate (m³/s), and H is the head (m). Closed impellers excel in high-head, low-flow applications, which are common in high-speed rotating devices.

Material and Manufacturing Considerations

The choice of materials for closed impellers is critical to their performance in high-speed applications. Common materials include stainless steel (e.g., 316 SS), cast iron, and high-strength alloys such as titanium or nickel-based alloys. These materials are selected based on their resistance to corrosion, erosion, and fatigue under high centrifugal forces.

For example, in a centrifugal compressor operating at 8000 rpm, the impeller may experience centrifugal stresses up to 300 MPa. Titanium alloys, with a yield strength of 900–1200 MPa, are often used to ensure durability. The shrouds are typically precision-cast or machined to achieve a smooth surface finish (e.g., Ra 0.8–1.6 µm), which reduces friction losses and enhances hydraulic efficiency.

Manufacturing closed impellers is more complex and costly than open or semi-open designs due to the need for precise shroud attachment and balancing. The shrouds are often welded or cast integrally with the vanes, requiring advanced techniques such as investment casting or CNC加工. Despite the higher cost, the improved performance and longevity justify their use in high-speed applications.

Application-Specific Advantages

Closed impellers are widely used in applications requiring high reliability and efficiency, such as water treatment, chemical processing, and oil and gas industries. Their ability to handle clean liquids with minimal solids makes them ideal for large centrifugal pumps, where flow rates can range from 100 to 10,000 m³/h and heads from 50 to 1000 meters.

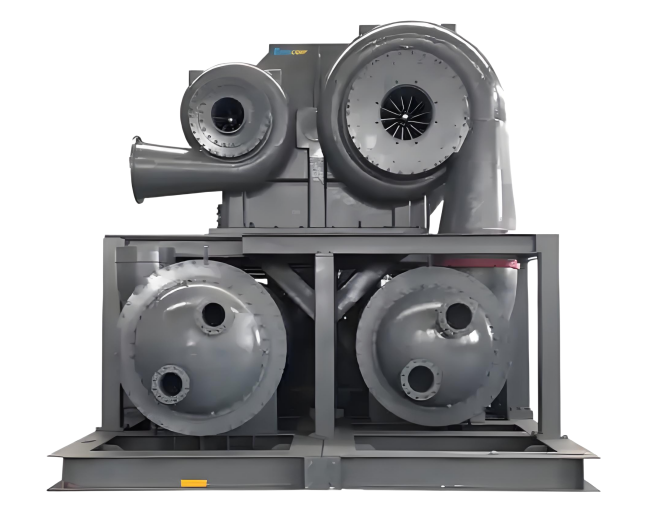

In high-speed compressors, closed impellers are used in multistage configurations to achieve pressure ratios of 3:1 to 10:1 per stage. The enclosed design ensures consistent performance across multiple stages, minimizing losses due to inter-stage leakage. For example, in a gas turbine compressor, a closed impeller can achieve a stage efficiency of 88–92%, compared to 80–85% for semi-open designs.

In medical applications, such as ventricular assist devices, closed impellers with magnetic levitation operate at 5000–8000 rpm, providing flow rates of 5–10 liters per minute. The enclosed design reduces shear stress on blood cells, minimizing hemolysis and ensuring biocompatibility.

Limitations of Closed Impellers

While closed impellers offer significant advantages, they have limitations that must be considered. Their enclosed design makes them prone to clogging when handling fluids with suspended solids, limiting their use in applications like wastewater treatment. The complex manufacturing process also increases costs, with closed impellers typically 20–30% more expensive than open designs.

Maintenance is another consideration, as accessing the internal vanes for inspection or cleaning is more difficult compared to open impellers. Wear rings require periodic replacement, typically every 1–2 years, depending on operating conditions, to maintain efficiency.

The table below outlines key considerations for closed impellers:

| パラメータ | Closed Impeller Characteristics | Impact |

|---|---|---|

| Solids Handling | Limited to clean fluids | Prone to clogging with solids |

| Manufacturing Cost | 20–30% higher than open impellers | Increased initial investment |

| Maintenance | Requires wear ring replacement | Higher maintenance complexity |

結論

Closed impellers are the preferred choice for high-speed rotating devices due to their superior structural integrity, hydraulic efficiency, and operational stability. Their ability to handle high pressures, operate across a wide range of specific speeds, and maintain efficiency under demanding conditions makes them indispensable in applications like centrifugal pumps, compressors, and medical devices. While they have limitations, such as higher manufacturing costs and limited solids handling, their benefits outweigh these drawbacks in high-speed, high-reliability applications. By understanding the technical principles and design considerations, engineers can optimize the performance of closed impellers in various industrial and specialized contexts.