5-axis machining is a cornerstone of modern precision manufacturing, enabling the production of complex geometries with high accuracy and efficiency. This guide provides a detailed exploration of its characteristics, compatible materials, and primary applications, offering a clear, systematic, and professional perspective for engineers, manufacturers, and industry professionals.

Characteristics of 5-Axis Machining

5-axis machining refers to a CNC (Computer Numerical Control) process where the cutting tool or workpiece moves along five distinct axes simultaneously. These axes include three linear axes (X, Y, Z) and two rotational axes (typically A and B, or A and C, depending on the machine configuration). This capability distinguishes it from traditional 3-axis machining, offering enhanced flexibility and precision.

Axis Definitions and Movements

The five axes in 5-осевая обработка are defined as follows:

- X-axis: Linear movement left to right.

- Y-axis: Linear movement forward and backward.

- Z-axis: Linear movement up and down, typically aligned with the tool spindle.

- A-axis: Rotational movement around the X-axis.

- B-axis: Rotational movement around the Y-axis (or C-axis around the Z-axis in some configurations).

These axes allow the cutting tool to approach the workpiece from multiple angles, enabling complex cuts without repositioning. For example, a 5-axis machine can tilt the tool or rotate the workpiece to machine five sides in a single setup, reducing manual intervention and improving accuracy.

Key Technical Features

5-axis machining offers several defining features that enhance its utility in precision manufacturing:

- Single Setup Machining: Unlike 3-axis machines, which often require multiple setups to access different part surfaces, 5-axis machines can machine up to five faces in one operation. This reduces setup time and minimizes alignment errors, achieving tolerances as tight as ±0.0005 inches (0.0127 mm).

- Возможность работы со сложными геометриями: The additional rotational axes enable the machining of intricate shapes, such as curved surfaces, undercuts, and deep cavities, which are challenging or impossible with 3-axis systems.

- Improved Surface Finish: By maintaining the cutting tool tangential to the workpiece surface, 5-axis machining reduces vibration and allows the use of shorter tools, resulting in smoother finishes with surface roughness (Ra) as low as 0.4–0.8 µm.

- Faster Material Removal: The ability to optimize tool angles increases material removal rates, with some operations achieving up to 30–40% faster cycle times compared to 3-axis machining.

- Enhanced Tool Life: Shorter cutting tools and optimized cutting paths reduce tool wear, extending tool life by up to 20% in high-speed milling applications.

These characteristics make 5-axis machining ideal for industries requiring high precision and complex part designs, such as aerospace, medical, and mold manufacturing.

Types of 5-Axis Machine Configurations

5-axis machines come in various configurations, each suited to specific applications:

| Configuration Type | Описание | Key Advantages |

|---|---|---|

| Trunnion Table | The workpiece is mounted on a table that rotates on A and C axes, while the tool moves linearly on X, Y, and Z axes. | High rigidity, supports larger workpieces, excellent for undercuts and mold making. |

| Swivel Head | The tool spindle rotates on A and B axes, while the table moves linearly on X, Y, and Z axes. | High torque for heavy cutting, ideal for dense materials like titanium. |

| Gantry Machine | Rotary axes are mounted on a moving bridge, suitable for large components. | Handles heavy workpieces, common in aerospace for large structural parts. |

| Nutating Machine | Features a non-orthogonal rotary axis (e.g., 45° from vertical), compact design. | Space-efficient, suitable for smaller, complex parts but limited in tool orientation. |

Each configuration is selected based on part size, material, and machining requirements, ensuring optimal performance for specific applications.

Materials Suitable for 5-Axis Machining

5-axis machining is highly versatile, accommodating a wide range of materials due to its ability to handle complex cutting paths and maintain precision. Material selection depends on factors such as mechanical properties, heat resistance, and application requirements. Below are the primary material categories used in 5-axis machining.

Металлы и сплавы

Metals are the most common materials in 5-axis machining due to their durability and widespread use in high-precision industries. Key metals include:

- Алюминий: Lightweight, corrosion-resistant, and easy to machine. Commonly used in aerospace for structural components, with typical cutting speeds of 300–600 m/min and feed rates of 0.1–0.3 mm/tooth.

- Нержавеющая сталь: Offers high strength and corrosion resistance, used in medical and automotive parts. Requires slower cutting speeds (50–150 m/min) due to its hardness.

- Титан: Known for low thermal expansion and high strength-to-weight ratio, ideal for aerospace and medical implants. Cutting speeds are typically 30–60 m/min to minimize heat buildup.

- Nickel-Based Alloys: Heat-resistant and used in turbine blades and energy sector components. Machining requires high-torque spindles and cutting speeds of 20–50 m/min.

- Copper and Brass: Conductive and corrosion-resistant, used in electronics and precision instruments. Cutting speeds range from 200–400 m/min.

Specialty alloys like Invar and Kovar are also used for their low thermal expansion, ensuring dimensional stability during complex cuts.

Пластмассы

Plastics are widely used in 5-axis machining for applications requiring lightweight and corrosion-resistant parts. Common plastics include:

- ABS: Durable and cost-effective, used in consumer goods and prototypes. Machining speeds are 100–300 m/min with feed rates of 0.05–0.2 mm/tooth.

- PEEK: High-performance plastic with biocompatibility, used in medical devices. Requires careful heat management with cutting speeds of 50–150 m/min.

- Nylon (PA): Tough and flexible, used in electronics and automotive components. Machining speeds range from 100–200 m/min.

- Поликарбонат (PC): Transparent and impact-resistant, used in optical and medical applications. Cutting speeds are typically 150–250 m/min.

- PTFE: Low-friction and chemically resistant, used in seals and gaskets. Machining requires low speeds (50–100 m/min) to prevent melting.

Composites and Ceramics

Advanced materials like composites and ceramics are increasingly used in 5-axis machining for specialized applications:

- Carbon Fiber Reinforced Plastic (CFRP): Lightweight and high-strength, used in aerospace and automotive parts. Requires diamond-coated tools and cutting speeds of 100–200 m/min to prevent delamination.

- Керамика: High hardness and wear resistance, used in semiconductor and medical applications. Machining requires ultra-precision tools and speeds of 20–50 m/min.

Material selection is critical, as properties like hardness, thermal conductivity, and machinability affect tool choice, cutting parameters, and final part quality.

Applications of 5-Axis Machining

5-axis machining is widely adopted in industries requiring high precision, complex geometries, and efficient production. Its applications span multiple sectors, each leveraging its unique capabilities.

Аэрокосмическая промышленность

The aerospace sector relies heavily on 5-axis machining for components with complex geometries and tight tolerances. Key applications include:

- Лопасти турбины: Require precise curvature and smooth surfaces, machined from titanium or nickel-based alloys with tolerances of ±0.01 mm.

- Структурные компоненты: Complex brackets and fairings made from aluminum or composites, benefiting from single-setup machining to reduce errors.

- Рабочие колеса: Feature intricate blade geometries, machined in one operation to ensure balance and precision.

5-axis machining ensures high accuracy and repeatability, critical for aerospace safety and performance standards.

Медицинская промышленность

Medical device manufacturing demands biocompatibility, precision, and smooth finishes, making 5-axis machining essential. Applications include:

- Ортопедические имплантаты: Titanium or cobalt-chrome implants, such as hip and knee joints, machined to tolerances of ±0.005 mm for perfect fit.

- Dental Implants: Require intricate shapes and polished surfaces, often machined from zirconia or titanium.

- Хирургические инструменты: Precision tools with complex geometries, machined from stainless steel or PEEK for durability and biocompatibility.

The ability to machine five surfaces in one setup ensures consistency and reduces production time for critical medical components.

Автомобильная промышленность

5-axis machining supports high-volume production of complex automotive parts, improving efficiency and quality. Key applications include:

- Engine Components: Cylinder heads and crankshafts machined from aluminum or steel with tolerances of ±0.02 mm.

- Transmission Parts: Gears and housings requiring precise contours and smooth finishes.

- Прототипирование: Rapid production of complex prototypes for high-end vehicles, reducing development time.

The technology’s efficiency in single-setup machining lowers costs in high-throughput automotive production.

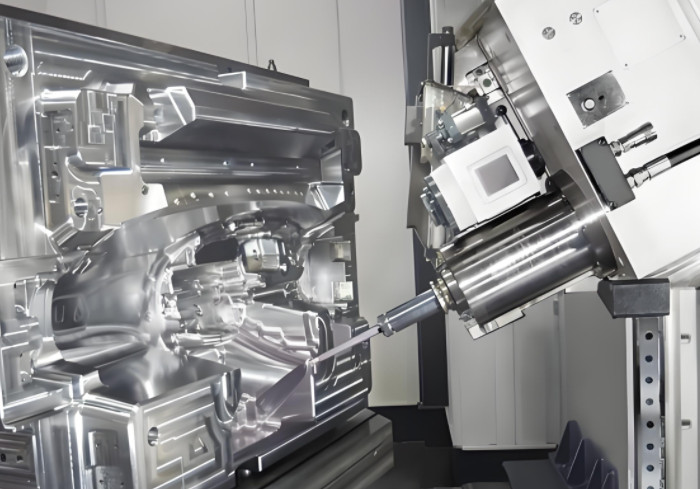

Mold and Die Manufacturing

Mold and die production benefits significantly from 5-axis machining due to the need for complex contours and high precision. Applications include:

- Injection Molds: Intricate cavities and cores machined from hardened steel with surface finishes of Ra 0.4 µm.

- Die Casting Molds: Complex shapes for automotive and consumer goods, machined in a single setup to reduce lead times.

- Stamping Dies: Multi-angle surfaces machined with high accuracy to ensure part consistency.

5-axis machining reduces mold production time by up to 50% compared to 3-axis methods, enhancing throughput and quality.

Technical Considerations

While 5-axis machining offers significant advantages, certain technical considerations must be addressed to ensure optimal performance:

- Programming Complexity: Generating accurate tool paths requires advanced CAM software and skilled programmers. Errors in G-code can lead to tool collisions or suboptimal cuts.

- Жесткость машины: High-speed 5-axis operations demand robust machine structures to minimize vibration and maintain precision.

- Tool Accessibility: While 5-axis machines improve access, deep cavities or narrow features may still require specialized tools or hybrid manufacturing approaches.

These considerations highlight the importance of proper setup, operator expertise, and equipment quality in achieving desired outcomes.

Заключение

5-axis machining is a transformative technology in precision manufacturing, offering unmatched flexibility, accuracy, and efficiency. Its ability to handle complex geometries, diverse materials, and demanding applications makes it indispensable in industries like aerospace, medical, automotive, and mold making. By understanding its characteristics, material compatibility, and applications, manufacturers can leverage 5-axis machining to produce high-quality parts with minimal setups and superior finishes. With proper implementation, this technology delivers reliable, repeatable results, meeting the stringent demands of modern engineering.

Frequently Asked Questions (FAQ) About 5-Axis Machining

What is 5-axis machining?

5-axis machining is a CNC (Computer Numerical Control) process where the cutting tool or workpiece moves simultaneously along five axes: three linear (X, Y, Z) and two rotational (typically A and B or A and C). This allows for complex geometries to be machined with high precision in a single setup.

How does 5-axis machining differ from 3-axis machining?

Unlike 3-axis machining, which moves only along X, Y, and Z axes, 5-axis machining includes two additional rotational axes. This enables machining of complex shapes, multiple surfaces, and intricate features without repositioning the workpiece, reducing setup time and improving accuracy.

What are the main benefits of 5-axis machining?

Ключевые преимущества включают:

Single setup machining: Reduces setup time and alignment errors.

Complex geometry capability: Machines intricate shapes like curved surfaces and undercuts.

Improved surface finish: Achieves smoother finishes (Ra 0.4–0.8 µm) with shorter tools.

Faster cycle times: Up to 30–40% faster material removal compared to 3-axis systems.

Extended tool life: Optimized tool paths reduce wear by up to 20%.

What materials can be used with 5-axis machining?

5-axis machining is versatile and works with:

Metals: Aluminum, stainless steel, titanium, nickel-based alloys, copper, brass.

Plastics: ABS, PEEK, nylon, polycarbonate, PTFE.

Composites and Ceramics: CFRP, ceramics for aerospace and medical applications.

Material choice depends on properties like hardness and thermal conductivity.

What are the tolerances achievable with 5-axis machining?

5-axis machining can achieve tolerances as tight as ±0.0005 inches (0.0127 mm) for general applications and ±0.005 mm for critical components like medical implants.

Where can I learn more about implementing 5-axis machining?

Consult machine manufacturers, CAM software providers, or industry resources for training and technical guidance. For specific applications, reach out to precision machining service providers or industry associations for expert advice.