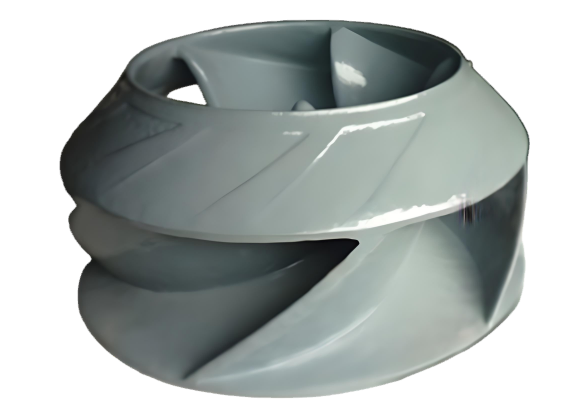

Impellers, critical components in pumps, turbines, and compressors, operate in harsh environments where corrosion can significantly reduce service life and performance. Enhancing corrosion resistance through optimized machining processes is essential for ensuring reliability and longevity. This article details three proven techniques—material selection and alloying, surface treatment and coatings, and precision machining and finishing—with specific parameters and practical considerations. The content is structured to provide a systematic, professional, and experience-based guide for engineers and manufacturers.

Material Selection and Alloying

The choice of material forms the foundation of an impeller’s corrosion resistance. Selecting appropriate alloys tailored to the operating environment—such as acidic, alkaline, or saline conditions—prevents degradation and extends component life. Alloying elements like chromium, nickel, and molybdenum enhance resistance to pitting, crevice corrosion, and general surface attack.

Stainless steels, such as AISI 316L, are widely used due to their balance of cost and performance. For more aggressive environments, duplex stainless steels (e.g., UNS S32205) or nickel-based alloys (e.g., Inconel 625) offer superior resistance. The table below summarizes key material options and their corrosion-resistant properties.

| Материал | Key Alloying Elements | Устойчивость к коррозии | Типовые применения | PREN (Pitting Resistance Equivalent Number) |

|---|---|---|---|---|

| AISI 316L Stainless Steel | Cr (16-18%), Ni (10-14%), Mo (2-3%) | Good resistance to general corrosion and pitting in mildly aggressive environments | Water pumps, mild chemical processing | 24-26 |

| Duplex Stainless Steel (UNS S32205) | Cr (22-23%), Ni (4.5-6.5%), Mo (3-3.5%) | Excellent resistance to pitting and crevice corrosion in chloride-rich environments | Seawater pumps, desalination plants | 35-36 |

| Inconel 625 | Ni (58% min), Cr (20-23%), Mo (8-10%) | Superior resistance to acidic and high-temperature corrosion | Chemical processing, marine environments | 40-45 |

Parameters for Material Selection:

- Environment Analysis: Assess pH, temperature (e.g., 20-80°C for 316L, up to 200°C for Inconel), and chloride concentration (e.g., <200 ppm for 316L, >1000 ppm for duplex).

- Mechanical Requirements: Ensure tensile strength (e.g., 485 MPa for 316L, 690 MPa for UNS S32205) and hardness (e.g., 217 HB max for 316L) meet design needs.

- Cost Consideration: Balance performance with budget; duplex steels cost 1.5-2 times more than 316L, while Inconel may be 3-5 times higher.

Practical Considerations: During alloying, maintain precise control over composition to avoid segregation. Use vacuum arc remelting (VAR) for high-purity alloys like Inconel to minimize inclusions. Verify material certifications to ensure compliance with ASTM or ISO standards.

Surface Treatment and Coatings

Surface treatments and coatings create protective barriers that shield impellers from corrosive agents. These methods enhance resistance without altering the bulk material, making them cost-effective for standard alloys. Common techniques include passivation, electroplating, and advanced coatings like plasma-sprayed ceramics or physical vapor deposition (PVD).

Passivation: This chemical process removes surface contaminants and forms a stable oxide layer. For 316L stainless steel, nitric acid passivation (20-40% concentration, 20-50°C, 30-60 minutes) increases the chromium oxide layer thickness to 2-5 nm, improving pitting resistance.

Electroplating: Nickel or chromium plating adds a 10-50 µm layer that resists corrosion in acidic or alkaline environments. For example, a 25 µm nickel coating on carbon steel impellers can extend life in pH 4-8 solutions by 2-3 times.

Advanced Coatings: Plasma-sprayed ceramic coatings (e.g., Al₂O₃-TiO₂, 100-300 µm thickness) provide exceptional resistance to abrasive and corrosive wear in high-velocity flows (e.g., 10-20 m/s). PVD coatings like titanium nitride (TiN, 1-5 µm) offer hardness (2000-2500 HV) and low friction, reducing erosion-corrosion.

Parameters for Surface Treatment:

- Passivation: Use ASTM A967 standards; ensure surface cleanliness with a water break test post-treatment.

- Electroplating: Control current density (1-5 A/dm²) and bath temperature (40-60°C) for uniform coating thickness.

- Plasma Spraying: Maintain spray distance (100-150 mm) and plasma temperature (10,000-15,000°C) for optimal adhesion (bond strength >50 MPa).

Practical Considerations: Surface preparation is critical; use grit blasting (e.g., 60-120 mesh alumina) to achieve a surface roughness of Ra 2-4 µm before coating. Regularly inspect coatings for defects like pinholes using dye penetrant testing. In saline environments, combine passivation with coatings for synergistic protection.

Precision Machining and Finishing

Precision machining and surface finishing reduce surface irregularities that act as corrosion initiation sites. Smooth surfaces minimize crevices where corrosive agents accumulate, while controlled machining prevents microstructural damage that could compromise corrosion resistance.

Machining Techniques: Use computer numerical control (CNC) milling or turning with low feed rates (0.05-0.1 mm/rev) and cutting speeds (50-100 m/min for stainless steel) to achieve surface roughness of Ra 0.4-0.8 µm. Avoid excessive heat generation, which can induce residual stresses or phase transformations in alloys like duplex stainless steel.

Surface Finishing: Polishing or superfinishing can reduce Ra to 0.1-0.2 µm, significantly lowering corrosion susceptibility. Electropolishing, using a phosphoric-sulfuric acid electrolyte (50-70°C, 5-10 A/dm²), removes 10-20 µm of surface material, enhancing both smoothness and passivation.

Parameters for Machining and Finishing:

- Обработка с ЧПУ: Use carbide tools with TiAlN coatings; maintain coolant flow (e.g., 10-20 L/min) to reduce thermal effects.

- Полировка: Employ diamond abrasives (1-6 µm grit) for final stages to achieve mirror-like finishes.

- Electropolishing: Control voltage (10-20 V) and process time (5-15 minutes) for uniform material removal.

Practical Considerations: Monitor tool wear to prevent surface defects; replace tools after 50-100 machining cycles for stainless steel. Post-machining, clean surfaces with acetone to remove contaminants. Use profilometers to verify surface roughness, ensuring compliance with ISO 4287 standards.

Implementation and Quality Control

Effective implementation of these techniques requires rigorous quality control. Conduct material testing (e.g., ASTM G48 for pitting corrosion) to validate alloy performance. For coatings, perform adhesion tests (e.g., ASTM D3359) and thickness measurements using eddy current or ultrasonic methods. Post-machining, use non-destructive testing (e.g., X-ray fluorescence) to confirm surface integrity.

Quality Control Parameters:

| Процесс | Test Method | Acceptance Criteria |

|---|---|---|

| Выбор материала | ASTM G48 (Pitting Test) | No pitting at 25°C for 316L, 40°C for duplex |

| Surface Coating | ASTM D3359 (Adhesion Test) | 4B or better (minimal flaking) |

| Прецизионная обработка | ISO 4287 (Surface Roughness) | Ra ≤ 0.8 µm for machined surfaces |

Practical Considerations: Develop standard operating procedures (SOPs) for each process. Train personnel on equipment handling and testing protocols. Maintain detailed records of process parameters and test results for traceability.

Заключение

Enhancing impeller corrosion resistance through material selection, surface treatments, and precision machining is a systematic process that demands technical expertise and rigorous control. By selecting appropriate alloys (e.g., 316L or duplex stainless steel), applying protective coatings (e.g., plasma-sprayed ceramics), and achieving smooth surfaces (Ra 0.1-0.8 µm), manufacturers can significantly extend impeller life in corrosive environments. The detailed parameters and practical considerations provided ensure reliable implementation, making this guide a valuable resource for engineers seeking durable, high-performance impellers.