Selecting the right CNC factory is a pivotal decision for manufacturers aiming to produce high-quality, precise components. The equipment capability of a CNC factory directly influences production outcomes, impacting precision, efficiency, and cost-effectiveness. This guide delves into the critical aspects of equipment capability, offering a systematic and professional perspective to help businesses make informed choices. By focusing on technical details, material compatibility, and operational parameters, we aim to provide a trustworthy and experience-based framework for evaluating CNC factories.

Understanding CNC Equipment Capability

Equipment capability in a CNC factory refers to the technical specifications, performance metrics, and operational versatility of the machines used for manufacturing. These machines, controlled by computer numerical control (CNC) systems, execute precise instructions to shape raw materials into finished parts. The capability of these machines determines their ability to meet specific project requirements, including tolerances, material types, and production volumes. A factory with robust equipment capabilities can handle diverse tasks, from milling and turning to complex multi-axis operations, ensuring consistent quality and efficiency.

The importance of equipment capability lies in its direct correlation with the quality of the final product. Factories with advanced CNC machines can achieve tighter tolerances, work with a broader range of materials, and execute complex geometries. Understanding these capabilities requires evaluating machine types, precision levels, and software integration, which we will explore in detail below.

Key Factors in Evaluating CNC Equipment Capability

To assess a CNC factory’s equipment capability, several technical factors must be considered. These include machine types, precision and tolerances, material compatibility, spindle power, and software integration. Each factor contributes to the factory’s ability to deliver components that meet design specifications.

Machine Types and Their Applications

CNC factories typically employ a variety of machines, each designed for specific tasks. The type of machine available in a factory significantly impacts its ability to handle different projects. Common CNC machine types include:

| Тип машины | Primary Function | Типовые применения |

|---|---|---|

| Фрезерные станки с ЧПУ | Use rotary cutting tools to remove material from a workpiece | Flat surfaces, slots, pockets, and complex 3D shapes |

| Токарные станки с ЧПУ | Rotate the workpiece against a cutting tool | Cylindrical parts like shafts, bushings, and screws |

| CNC Laser Cutters | Use a focused laser beam to cut or engrave materials | Sheet metal cutting, intricate patterns, and engravings |

| CNC EDM (Electrical Discharge Machines) | Use electrical discharges to shape conductive materials | Precision molds, dies, and intricate metal parts |

A factory with a diverse range of machine types can address varied manufacturing needs, from producing automotive components to aerospace parts. For example, a CNC milling machine with 5-axis capability can create complex geometries that a 3-axis machine cannot, making it essential for industries requiring intricate designs.

Precision and Tolerance Capabilities

Precision is a cornerstone of Обработка на станках с ЧПУ, and a factory’s equipment must achieve tight tolerances to meet industry standards. Tolerances as low as ±0.005 mm are often required for high-precision industries like aerospace and medical device manufacturing. Advanced CNC machines with closed-loop feedback systems monitor axis positions using encoders, ensuring accuracy during operation. For instance, a high-precision CNC machine can maintain consistent tolerances across large production runs, reducing defects and ensuring part reliability.

When evaluating a factory, inquire about the tolerances their machines can achieve. For example, a CNC mill with a spindle runout of less than 0.002 mm indicates superior precision, suitable for critical applications. Factories should provide detailed specifications, including maximum deviation limits and repeatability metrics, to demonstrate their equipment’s precision capabilities.

Совместимость материалов

The ability of CNC equipment to process various materials is a critical consideration. CNC machines must handle metals (e.g., aluminum, stainless steel, titanium), plastics (e.g., ABS, PEEK), composites, and even softer materials like wood or foam. Material compatibility depends on the machine’s spindle power, tooling options, and cutting parameters.

For instance, machining titanium requires a CNC machine with a high-torque spindle (e.g., 20-30 kW) and robust tooling to withstand the material’s hardness. Conversely, softer materials like plastics may require lower spindle speeds to prevent melting or deformation. A factory with versatile equipment can switch between materials seamlessly, reducing setup times and ensuring process stability.

Key material-specific parameters include:

- Скорость вращения шпинделя: Typically ranges from 6,000 to 24,000 RPM, depending on material hardness.

- Cutting Feed Rate: Varies from 100 mm/min for hard metals to 1,000 mm/min for softer materials.

- Материал инструмента: Carbide tools for metals, diamond-coated tools for composites.

A factory’s ability to provide detailed material compatibility data reflects its technical expertise and operational flexibility.

Spindle Power and Tooling Options

The spindle is the heart of a CNC machine, driving the cutting tools that shape the workpiece. Spindle power, measured in kilowatts (kW), determines the machine’s ability to handle tough materials and maintain cutting efficiency. For example, a spindle with 15 kW of power is suitable for aluminum, while 30 kW or more is needed for stainless steel or titanium.

Tooling options also play a significant role. Modern CNC machines often feature automatic tool changers (ATCs) with capacities ranging from 20 to 60 tools, allowing for rapid tool swaps during complex operations. Factories with advanced tooling systems can handle intricate designs without requiring multiple setups, improving efficiency and reducing costs.

Software and Programming Integration

CNC machines rely on software to translate design files into machine instructions, typically using G-code or proprietary languages. Factories with advanced software integration, such as CAD/CAM systems, can optimize toolpaths, reduce machining time, and enhance precision. For example, CAM software like Mastercam or Siemens NX can simulate machining processes to detect potential errors before production begins.

Additionally, factories with real-time monitoring systems can track machine performance, ensuring consistent output. Closed-loop control systems, which use feedback from encoders, are essential for maintaining accuracy during high-speed operations. When selecting a factory, verify that their software supports industry-standard file formats (e.g., STEP, IGES) and integrates with your design workflow.

Operational Efficiency and Production Capacity

Equipment capability also influences a factory’s operational efficiency and production capacity. High-performance CNC machines can operate continuously, reducing downtime and increasing throughput. For example, a CNC lathe with a bar feeder can process multiple parts without manual intervention, ideal for high-volume production.

Key metrics to evaluate include:

- Cycle Time: Time to complete one part, influenced by spindle speed and feed rate.

- Setup Time: Time required to prepare the machine for a new job, minimized by ATCs and quick-change fixtures.

- Объем производства: Maximum output per shift, determined by machine speed and automation features.

A factory with high-capacity machines can handle both small-batch prototyping and large-scale production, offering flexibility for diverse project needs.

Quality Control and Inspection Capabilities

Equipment capability extends beyond machining to include quality control and inspection. Advanced CNC factories use coordinate measuring machines (CMMs) and laser scanners to verify part dimensions against design specifications. For example, a CMM with a measurement accuracy of ±0.001 mm can detect minute deviations, ensuring compliance with tight tolerances.

Factories should also have robust quality control processes, including:

- In-Process Inspection: Real-time monitoring during machining to detect errors early.

- Post-Process Inspection: Final checks using precision instruments to confirm part accuracy.

- Documentation: Detailed reports on tolerances, surface finish, and material properties.

These capabilities ensure that the factory can deliver parts that meet stringent quality standards, reducing the risk of costly rework.

Customization and Flexibility

A factory’s equipment capability determines its ability to handle custom projects. CNC machines with multi-axis capabilities (e.g., 5-axis mills) can produce complex geometries, such as turbine blades or medical implants, that require simultaneous movement in multiple directions. Factories with flexible equipment can also adapt to unique project requirements, such as non-standard materials or intricate designs.

For example, a CNC router with a large work envelope (e.g., 2000 x 1000 x 1000 mm) can accommodate oversized parts, while a machine with high-speed spindles can handle delicate engravings. Factories that invest in versatile equipment demonstrate their ability to meet diverse customer needs, enhancing their reliability as a partner.

Maintenance and Equipment Reliability

Reliable CNC equipment is essential for consistent production. Factories should implement preventive maintenance programs to minimize downtime and ensure machine longevity. Key maintenance practices include:

- Regular Calibration: Ensures machines maintain precision over time.

- Lubrication Schedules: Reduces wear on moving parts like spindles and bearings.

- Tool Inspection: Checks for wear or damage to maintain cutting accuracy.

A factory with well-maintained equipment is less likely to experience unexpected failures, ensuring timely delivery of parts. Ask for maintenance records and uptime statistics to gauge equipment reliability.

Experience and Technical Expertise

Equipment capability is only as effective as the team operating it. A factory with experienced technicians and programmers can maximize machine performance, optimizing parameters like feed rate (e.g., 500-2000 mm/min) and spindle speed for specific materials. Look for factories with a proven track record in your industry, as their expertise ensures they can handle complex projects and troubleshoot issues effectively.

For example, a factory with experience in aerospace machining will understand the stringent requirements for materials like Inconel, adjusting machining parameters to prevent tool wear or part deformation. Certifications like ISO 9001 or AS9100 further validate a factory’s technical proficiency.

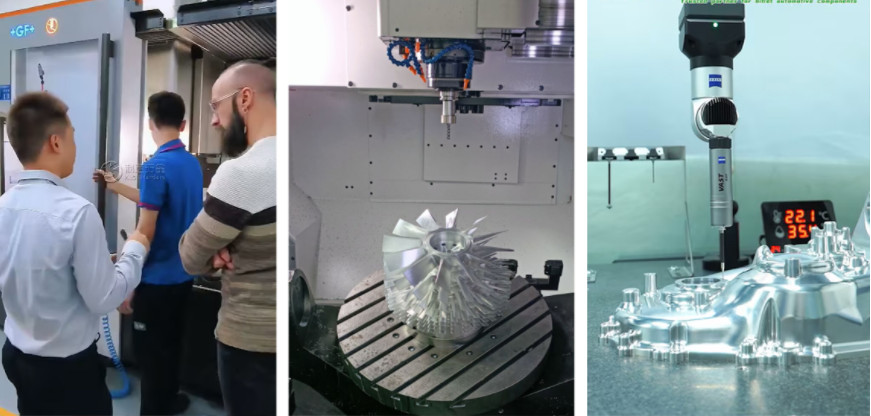

Kesu stands out in CNC machining factories

Kesu focuses on providing customers with the best services in rapid prototyping and low-volume production. Kesu has invested in more than 200 sets of advanced equipment, including 4-axis and 5-axis CNC machines, CNC lathes, 5-axis lathe mill combo machines, CNC Swiss-type automatic lathes, 3D printers, CMM, XRF spectrometers, Rockwell hardness testers, 3D measuring projectors, etc.

Заключение

Choosing a CNC factory with strong equipment capability is essential for achieving high-quality, precise, and cost-effective manufacturing outcomes. By evaluating machine types, precision levels, material compatibility, spindle power, software integration, and operational efficiency, businesses can select a partner that aligns with their project needs. Factories with diverse, well-maintained equipment and experienced teams offer the flexibility and reliability required for successful production. Prioritizing these factors ensures that your CNC manufacturing process meets industry standards and delivers consistent results, fostering trust and long-term collaboration.