Selecting a reliable CNC service provider is critical for ensuring high-quality parts that meet precise specifications in modern manufacturing. The evaluation process involves assessing technical capabilities, quality control systems, and operational reliability. This guide provides a detailed, systematic approach to evaluating CNC service providers based on machining precision and quality, focusing on measurable parameters and industry best practices. By following these steps, businesses can make informed decisions to partner with providers capable of delivering consistent, high-quality results.

Understanding CNC Machining Precision and Quality

CNC (Computer Numerical Control) machining relies on automated systems to control tools and machinery through precise programming. Precision refers to the ability to achieve tight tolerances, typically measured in microns or millimeters, while quality encompasses surface finish, material integrity, and adherence to specifications. Evaluating these aspects requires a deep understanding of technical metrics, equipment capabilities, and quality assurance processes. Key factors include machine accuracy, operator expertise, and inspection methodologies, all of which contribute to the final product's performance.

Key Metrics for Assessing Machining Precision

Precision in CNC machining is defined by how closely the machined part matches the design specifications. Below are the primary metrics to evaluate a service provider’s precision capabilities:

- Диапазон допусков: Tolerances are typically specified in terms of ±0.01 mm to ±0.001 mm for high-precision applications. Providers should demonstrate consistent achievement of these tolerances using calibrated equipment.

- Повторяемость: This measures the machine’s ability to produce identical parts across multiple runs. A repeatability of ±0.005 mm or better is often required for critical components in industries like aerospace or medical devices.

- Positional Accuracy: The ability of the CNC machine to move to the exact programmed coordinates. High-end machines achieve positional accuracy within ±0.002 mm.

- Surface Roughness (Ra): Surface finish is measured in micrometers (µm). For example, a Ra value of 0.8 µm indicates a smooth finish suitable for functional surfaces, while 0.4 µm or lower is required for high-precision applications.

Requesting detailed specifications from the provider, including machine datasheets and calibration records, ensures transparency in their ability to meet these metrics. Additionally, reviewing sample parts with measurement reports can validate claims about precision.

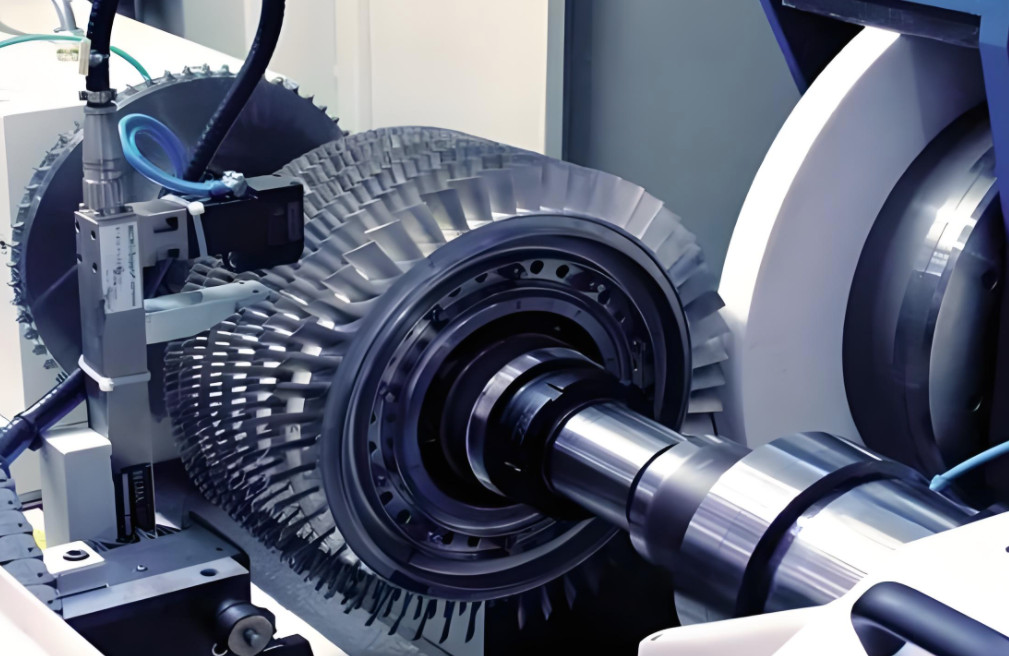

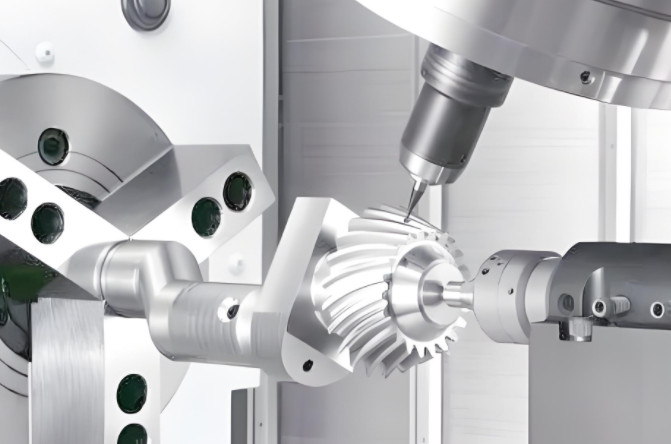

Evaluating Equipment and Technology

The quality of CNC equipment directly impacts precision and output. When assessing a CNC service provider, focus on the following equipment-related factors:

- Machine Type and Age: Modern 5-axis CNC machines offer greater flexibility and precision compared to 3-axis machines. Machines less than five years old typically incorporate advanced features like high-speed spindles (up to 30,000 RPM) and improved control systems.

- Tooling Quality: High-quality tools, such as carbide or diamond-coated cutters, reduce wear and maintain precision. Providers should use tools from reputable manufacturers and have a tool management system to monitor wear.

- Software Integration: Advanced CAD/CAM software ensures accurate translation of designs into machine instructions. Compatibility with industry-standard software like Siemens NX or Mastercam is a positive indicator.

- Maintenance Records: Regular maintenance, including spindle alignment and backlash compensation, ensures consistent performance. Request maintenance logs to verify upkeep schedules.

A provider with a diverse range of well-maintained machines, such as CNC lathes, milling centers, and EDM machines, is better equipped to handle complex projects. Visiting the facility to inspect equipment firsthand can provide valuable insights into their operational standards.

Quality Control Processes

Robust quality control (QC) systems are essential for ensuring consistent part quality. A reliable CNC service provider should have the following QC measures in place:

- In-Process Inspection: Real-time monitoring using probes or laser systems to detect deviations during machining. This reduces waste and ensures immediate corrective action.

- Final Inspection: Post-machining checks using coordinate measuring machines (CMM) or optical scanners to verify dimensions and surface quality. CMMs should have an accuracy of ±0.002 mm or better.

- Statistical Process Control (SPC): SPC uses statistical methods to monitor process stability. Providers should provide control charts showing Cp and Cpk values, with a Cpk of 1.33 or higher indicating a capable process.

- Traceability: Each part should be traceable to its production batch, including material certifications and inspection records. This is critical for industries like automotive and aerospace.

Ask for documentation of QC procedures, such as ISO 9001:2015 certification, which indicates adherence to international quality standards. Additionally, verify if the provider conducts regular audits of their QC processes to maintain reliability.

Material Handling and Expertise

The choice of materials and the provider’s expertise in handling them significantly affect machining quality. Consider the following:

- Material Knowledge: Providers should demonstrate expertise in machining various materials, such as aluminum (e.g., 6061-T6), stainless steel (e.g., 304 or 316), or exotic alloys like titanium (Ti-6Al-4V). Each material requires specific cutting parameters to avoid defects.

- Material Sourcing: Reliable providers source materials from certified suppliers and provide material test reports (MTRs) to confirm properties like hardness and composition.

- Терморегулирование: Materials with poor thermal conductivity, such as stainless steel, require precise coolant and cutting speed control to prevent thermal distortion. Providers should have systems to manage heat buildup.

Request case studies or examples of past projects involving materials similar to your requirements. This demonstrates the provider’s ability to handle specific material challenges effectively.

Operator Skill and Training

Even the best equipment requires skilled operators to achieve optimal results. Evaluate the provider’s workforce through:

- Certification and Training: Operators should be trained in CNC programming, G-code, and machine operation. Certifications from organizations like NIMS (National Institute for Metalworking Skills) add credibility.

- Experience Level: Operators with 5+ years of experience in CNC machining are better equipped to handle complex setups and troubleshoot issues.

- Staff Retention: Low turnover rates indicate a stable, experienced workforce. High turnover can lead to inconsistencies in quality.

Inquire about the provider’s training programs and operator-to-machine ratio. A ratio of 1:2 or better ensures adequate oversight during production.

Case Study Analysis and Past Performance

Reviewing a provider’s past performance provides insight into their reliability. Request:

- Sample Parts: Physical samples or detailed inspection reports of parts similar to your project requirements.

- Customer References: Contact previous clients to verify delivery times, quality consistency, and responsiveness.

- Defect Rates: Providers should share data on defect rates, ideally below 1% for high-precision industries.

Analyzing case studies or project portfolios helps assess whether the provider has experience with similar tolerances, materials, or industries. For example, a provider serving aerospace clients is likely adept at meeting stringent standards like AS9100.

Key Evaluation Parameters Table

| Параметр | Standard | Evaluation Method |

|---|---|---|

| Диапазон допусков | ±0.01 mm to ±0.001 mm | Review inspection reports, CMM data |

| Повторяемость | ±0.005 mm or better</LOL | Analyze production run data |

| Surface Roughness (Ra) | 0.4–0.8 µm for precision parts | Inspect sample parts, surface profilometer |

| Positional Accuracy | ±0,002 мм | Check machine specifications |

| Process Capability (Cpk) | ≥1.33 | Request SPC control charts |

This table summarizes critical parameters for precision and quality, along with methods to verify them during evaluation.

Common Issues in CNC Machining Quality

While not all providers face significant challenges, certain issues can affect machining quality. Addressing these during evaluation minimizes risks:

- Inconsistent Tolerances: Caused by worn tools or poor calibration. Ensure the provider has a tool replacement schedule and calibration records.

- Surface Imperfections: Result from improper cutting speeds or inadequate coolant. Verify the provider’s process for optimizing cutting parameters.

- Material Deformation: Common in materials like titanium due to excessive heat. Confirm the provider’s thermal management strategies.

Discussing these potential issues with the provider and reviewing their mitigation strategies demonstrates their commitment to quality.

Cost vs. Quality Considerations

While cost is a factor, prioritizing low prices over quality can lead to defects and rework. A balanced approach involves:

- Transparent Pricing: Providers should break down costs for setup, machining, and inspection to justify their rates.

- Long-Term Value: High-quality providers may charge more but reduce costs associated with scrap or delays.

- Scalability: Ensure the provider can handle varying production volumes without compromising precision.

Request quotes for small and large batches to assess cost-effectiveness while maintaining quality standards.

Заключение

Evaluating a CNC service provider’s machining precision and quality requires a systematic approach focusing on technical metrics, equipment capabilities, quality control, material expertise, and operator skills. By examining tolerance ranges, repeatability, surface finish, and process controls, businesses can ensure the provider meets their requirements. Requesting sample parts, case studies, and certifications like ISO 9001 further validates reliability. The provided table and issue analysis offer practical tools for assessment. By prioritizing these factors, you can select a CNC service provider that delivers consistent, high-quality results tailored to your manufacturing needs.