Computer Numerical Control (CNC) machining is a cornerstone of modern manufacturing, enabling the production of high-precision components across industries such as aerospace, automotive, and medical. An efficient CNC factory relies on three critical pillars: advanced technology, high-quality equipment, and optimized processes. This article provides a detailed examination of these factors, offering practical insights and technical considerations to ensure operational excellence. By focusing on these elements, manufacturers can achieve consistent quality, reduce waste, and enhance productivity.

Advanced Technology in CNC Machining

Technology is the backbone of an efficient CNC factory, driving precision, automation, and data-driven decision-making. The integration of sophisticated software, control systems, and monitoring tools ensures that CNC operations are accurate and repeatable.

CAD/CAM Software

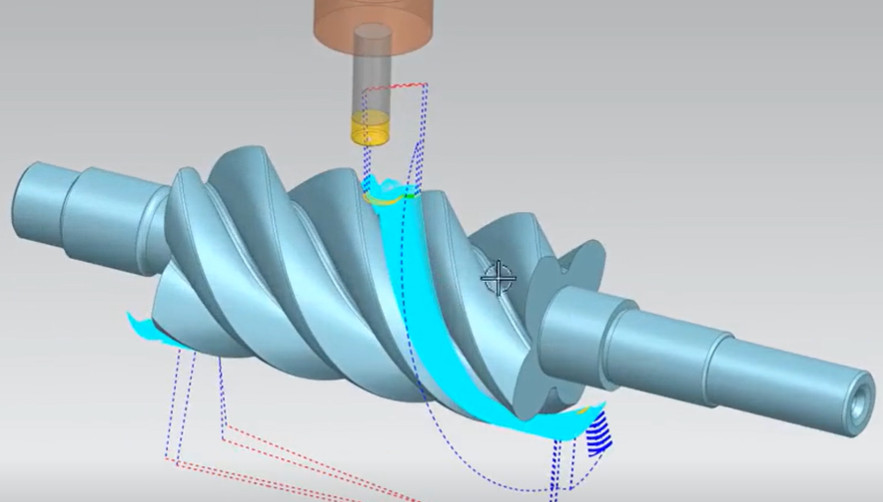

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are essential for translating design concepts into executable machine instructions. CAD software, such as AutoCAD or SolidWorks, allows engineers to create detailed 3D models with precise geometric dimensions, tolerances, and material specifications. CAM software, like Mastercam or Siemens NX, converts these designs into G-code or M-code, which CNC machines use to control tool paths and operations. A robust CAD/CAM workflow reduces programming errors and enables complex geometries, such as those required for aerospace components with tolerances as tight as ±0.025 mm.

Key considerations for CAD/CAM integration include compatibility with machine controllers, support for multi-axis machining (e.g., 5-axis systems), and the ability to simulate tool paths to prevent collisions. For example, a 5-axis CNC mill requires CAM software capable of handling simultaneous X, Y, Z, A, and B axis movements, ensuring smooth operation for intricate parts like turbine blades.

Control Systems and Feedback Loops

Modern CNC machines rely on closed-loop control systems to maintain precision. These systems use encoders to monitor the position of each axis, providing real-time feedback to the controller. For instance, a high-precision CNC lathe may use an incremental encoder with a resolution of 0.001 mm to ensure accurate positioning. Closed-loop systems correct deviations during machining, reducing errors caused by thermal expansion or tool wear. In contrast, open-loop systems, which lack feedback, are less reliable for high-precision tasks.

Advanced control systems also support real-time data collection, enabling operators to monitor spindle load, axis torque, and cutting parameters. For example, a CNC machine equipped with a Siemens SINUMERIK controller can log data at 1 ms intervals, allowing precise adjustments to feed rates and spindle speeds to optimize tool life and surface finish.

Automation and Integration

Automation technologies, such as robotic arms and pallet changers, enhance efficiency by reducing manual intervention. For instance, a CNC machining center with an automatic tool changer (ATC) can switch between tools in under 2 seconds, minimizing downtime. Integration with Manufacturing Execution Systems (MES) further streamlines operations by coordinating production schedules, tracking work-in-progress, and managing inventory. A factory producing automotive parts might use an MES to synchronize CNC milling and turning operations, ensuring a throughput of 500 parts per shift.

High-Quality CNC Equipment

The selection and maintenance of CNC equipment directly impact a factory’s ability to produce high-quality parts efficiently. Equipment must align with the specific requirements of the parts being manufactured, including material type, part complexity, and production volume.

Types of CNC Machines

CNC machines vary in type and capability, each suited to specific applications. The following table outlines common CNC machines and their specifications:

| Тип машины | Primary Function | Typical Specifications | Приложения |

|---|---|---|---|

| CNC Mill | Cutting and shaping materials in multiple axes | 3-5 axes, spindle speed: 10,000–20,000 RPM, worktable size: up to 2000 x 800 mm | Aerospace components, molds, prototypes |

| Токарный станок с ЧПУ | Turning cylindrical parts | 2-4 axes, max diameter: 500 mm, spindle speed: 4,000–6,000 RPM | Валы, bushings, medical implants |

| CNC Plasma Cutter | Cutting metal sheets with plasma torch | Cutting thickness: up to 50 mm, table size: 2000 x 4000 mm | Steel plates, structural components |

| CNC Water Jet | Cutting materials with high-pressure water | Pressure: 60,000 psi, cutting area: up to 3000 x 1500 mm | Stone, composites, heat-sensitive materials |

Selecting the right machine involves evaluating part dimensions, material hardness, and required tolerances. For example, a CNC mill with a 20,000 RPM spindle is ideal for machining aluminum aerospace parts, while a water jet cutter is better suited for titanium due to its heat-sensitive properties.

Tooling and Accessories

Tooling is critical to CNC efficiency. High-speed steel (HSS) or carbide tools are commonly used, with carbide offering superior durability for hard materials like stainless steel. Tool selection depends on cutting speed, feed rate, and material properties. For instance, a carbide end mill with a 0.5 mm corner radius can achieve a surface finish of Ra 0.8 µm on aluminum, while a diamond-coated tool is preferred for composites to prevent delamination.

Accessories like fixtures and clamps ensure part stability during machining. A vacuum chuck, for example, can secure thin sheets with a holding force of 100 N/cm², preventing vibration and ensuring accuracy. Proper tool and accessory selection reduces cycle times and defect rates, with advanced setups achieving scrap rates below 1%.

Equipment Maintenance

Regular maintenance is essential to prevent downtime and ensure consistent performance. A CNC machine requires lubrication every 500 hours of operation to prevent wear on guide rails and bearings. Cleaning schedules should remove debris and coolant residue to avoid spindle contamination. For example, a CNC machining center with improper lubrication may experience a 10% reduction in spindle accuracy over 1,000 hours. Calibration checks, conducted monthly, ensure axis alignment within ±0.01 mm, maintaining precision for high-tolerance parts.

Optimized CNC Processes

Efficient processes are the glue that binds technology and equipment, ensuring seamless production. Process optimization involves planning, parameter setting, and quality control to maximize throughput and minimize errors.

Process Planning

Effective process planning defines the sequence of operations, cutting parameters, and fixturing methods. A well-planned process for a complex part, such as an automotive gear, might involve roughing, semi-finishing, and finishing stages, each with specific feed rates (e.g., 0.2 mm/rev for roughing, 0.05 mm/rev for finishing). Planning also considers material removal rates, with high-speed machining achieving up to 800 cm³/min for aluminum. By optimizing tool paths, manufacturers can reduce cycle times by 15–20% while maintaining surface quality.

Machining Parameter Settings

Cutting parameters—speed, feed rate, and depth of cut—must be tailored to the material and part geometry. For example, machining stainless steel on a CNC mill might use a spindle speed of 2,000 RPM, a feed rate of 100 mm/min, and a depth of cut of 0.5 mm to balance tool life and surface finish. Incorrect parameters can lead to tool wear or part defects, such as burrs or dimensional inaccuracies. Advanced CNC systems allow dynamic adjustments, with adaptive control algorithms optimizing parameters in real time to maintain a tool life of over 10,000 minutes.

Quality Control and Inspection

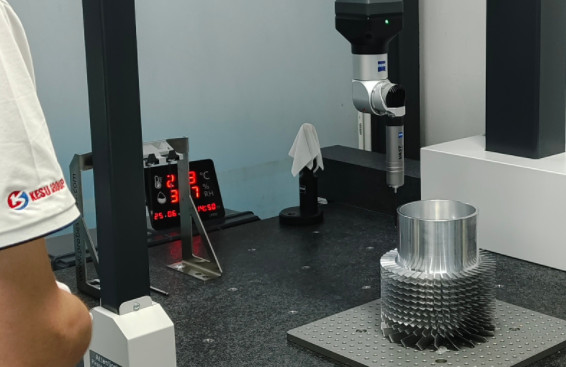

Quality control ensures that parts meet specifications. Coordinate Measuring Machines (CMMs) with a resolution of 0.001 mm can verify tolerances, while surface profilometers measure roughness to ensure finishes meet standards like Ra 0.4 µm for medical implants. Statistical Process Control (SPC) monitors production data, identifying deviations before they result in defects. For instance, a factory producing 1,000 parts daily might use SPC to maintain a CpK value above 1.33, ensuring process capability.

Workflow Coordination

Coordinating workflows across multiple CNC machines minimizes bottlenecks. A factory with 10 CNC mills and 5 lathes might use a scheduling system to prioritize high-volume jobs, achieving a machine utilization rate of 85%. Lean manufacturing principles, such as Just-In-Time (JIT) production, reduce inventory costs by 20–30% while ensuring timely delivery of parts like engine components.

Key Considerations for Implementation

Implementing these factors requires a systematic approach. Factories should start with a needs assessment to identify production goals, such as achieving a throughput of 10,000 parts per month or reducing cycle times by 15%. Investing in training ensures operators can leverage advanced technologies, with studies showing that trained operators improve productivity by 25%. Regular audits of equipment and processes, conducted quarterly, help identify inefficiencies, such as a 5% increase in scrap rate due to tool wear.

Budget constraints may limit investment in high-end equipment, but phased upgrades—starting with critical machines like 5-axis mills—can yield significant returns. For example, a factory upgrading to a 5-axis CNC machine reported a 30% reduction in setup times. Additionally, aligning technology, equipment, and processes with industry standards, such as ISO 9001, enhances credibility and ensures consistent quality.

Заключение

An efficient CNC factory hinges on the seamless integration of advanced technology, high-quality equipment, and optimized processes. CAD/CAM software, closed-loop control systems, and automation drive precision and productivity. Selecting the right machines and tools, coupled with rigorous maintenance, ensures reliability. Process planning, parameter optimization, and quality control minimize waste and maximize output. By addressing these factors systematically, manufacturers can achieve operational excellence, producing high-precision parts that meet the demands of industries worldwide.