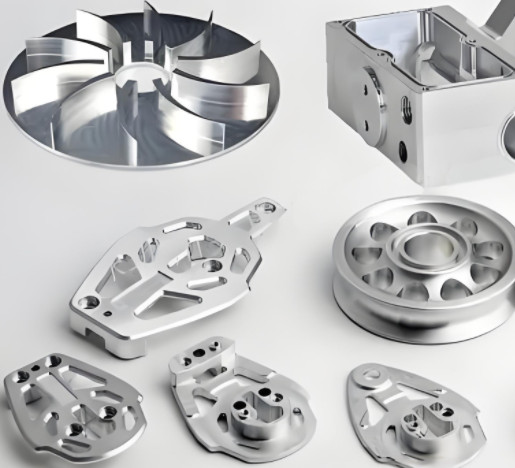

Selecting a CNC machining service provider requires careful evaluation to balance cost, quality, and efficiency. Effective cost control is critical to ensure that projects meet budget constraints while maintaining high standards. This guide outlines key considerations for controlling costs when choosing a CNC service provider, emphasizing material selection, design optimization, production efficiency, quality control, and supplier capabilities. Each factor is analyzed to provide actionable insights for decision-makers in manufacturing industries such as automotive, aerospace, and medical device production.

Material Selection and Cost Management

Material choice significantly impacts CNC machining costs due to variations in raw material prices, machinability, and processing requirements. Selecting the appropriate material involves balancing performance needs with cost efficiency.

Common materials like aluminum 6061 are cost-effective due to their availability and ease of machining, with an average cost of $2-$5 per pound. In contrast, exotic materials like titanium or Inconel are more expensive, costing $20-$50 per pound, and require specialized tools and slower machining speeds, increasing labor and machine time. For example, titanium’s high strength-to-weight ratio is ideal for aerospace components, but its hardness can increase tool wear by 20-30%, raising costs.

To control costs, verify the supplier’s ability to source materials efficiently. Providers with established supply chains can secure materials at lower prices, reducing overall project costs by 10-15%. Additionally, consider using alternative materials with similar properties. For instance, substituting stainless steel 304 for 316 in non-corrosive environments can save up to 20% on material costs without compromising quality.

Another consideration is material waste. CNC machining is a subtractive process, so optimizing material usage through precise design can minimize scrap. Suppliers offering material utilization analysis can reduce waste by up to 25%, directly lowering costs.

Design Optimization for Cost Efficiency

Part design directly affects machining time, tool usage, and overall costs. Complex designs with tight tolerances or intricate geometries increase programming time, setup complexity, and machining duration, driving up expenses.

Tolerance Settings: Tight tolerances, such as ±0.001 inches, require advanced equipment and additional inspection steps, increasing costs by 15-30%. For non-critical features, standard tolerances of ±0.005 inches can reduce machining time and costs while maintaining functionality. Collaborate with the supplier to set realistic tolerances based on part requirements.

Geometry Simplification: Complex features like undercuts, deep cavities, or thin walls increase machining time and tool costs. For example, ultra-deep cavities (depth-to-diameter ratio > 10:1) may require specialized tools, adding 20-40% to costs. Simplifying designs, such as increasing inner diameter sizes to allow larger end mills, can improve machining speed by 15-25% and reduce tool wear.

Wall Thickness: For metal parts, maintain a minimum wall thickness of 0.5 mm, and for plastics, 1.0 mm, to prevent deformation or cracking during machining. Thin walls require slower machining speeds and additional care, increasing costs by 10-20%. Suppliers with CAD/CAM expertise can simulate designs to identify cost-saving opportunities before production begins.

Design for Manufacturability (DFM): Engage suppliers early in the design phase for DFM feedback. Providers using 3D modeling and simulation can identify potential issues, such as tool inaccessibility, reducing setup time by up to 20% and avoiding costly rework.

Production Efficiency and Machine Capabilities

Production efficiency depends on the supplier’s equipment, capacity, and operational expertise. Advanced machinery and high-capacity facilities can reduce machining time and costs.

Equipment Quality: Modern CNC machines with high-speed spindles (18,000-24,000 RPM) and advanced controls improve efficiency, reducing cycle times by 15-30% compared to older machines. For example, 5-axis machining centers can process multiple sides of a part in one setup, cutting production time by up to 40% compared to 3-axis machines. Verify the supplier’s equipment list to ensure they have the necessary capabilities for your project.

Production Capacity: Suppliers with multiple machines can handle high-volume orders without delays. For instance, a facility with 50+ CNC machines can process orders 20-30% faster than one with fewer than 10 machines. Confirm the supplier’s capacity to meet your production schedule, especially for time-sensitive projects.

Automation Integration: Suppliers using automated systems, such as robotic arms for loading/unloading, can reduce labor costs by 10-20%. Automation also minimizes human error, ensuring consistent quality and reducing rework expenses.

Machining Time Reduction: Efficient programming and toolpath optimization can reduce machining time. For example, using high-feed milling strategies can decrease cycle times by 15-25%. Suppliers with skilled programmers can implement these strategies to lower costs without sacrificing quality.

Quality Control and Inspection Processes

Robust quality control (QC) ensures parts meet specifications, preventing costly rework or defects. However, excessive QC measures can increase costs, so balance is key.

Inspection Equipment: Suppliers using advanced tools like Coordinate Measuring Machines (CMMs) and optical comparators can verify part accuracy to within ±0.0005 inches. Regular calibration of inspection tools ensures reliability, reducing defect rates by 10-15%. Confirm the supplier’s QC capabilities to avoid unexpected costs from non-compliant parts.

Quality Management Systems: Certifications like ISO 9001 or AS9100 indicate a systematic approach to quality. These systems reduce error rates by 5-10% through standardized processes. For regulated industries like aerospace, AS9100 compliance is mandatory to ensure parts meet stringent standards.

Traceability: Suppliers offering material and process traceability provide assurance against defects, reducing liability risks. Traceability systems can lower rework costs by 10-20% by identifying issues early in production.

Balancing QC Costs: Excessive inspections, such as 100% part checks, can increase costs by 15-25%. For non-critical components, statistical process control (SPC) can reduce inspection frequency while maintaining quality, saving 5-10% on QC expenses.

Supplier Experience and Expertise

The supplier’s experience and technical expertise directly influence cost control. Experienced providers can anticipate challenges, optimize processes, and deliver consistent results.

Industry-Specific Knowledge: Suppliers with experience in your industry (e.g., automotive or medical) understand specific requirements, such as material certifications or regulatory compliance. This expertise reduces errors by 10-15% and avoids costly delays due to non-compliance.

Technical Proficiency: Skilled operators and programmers can optimize toolpaths and setups, reducing machining time by 10-20%. For example, experienced programmers can minimize tool changes, saving 5-10% on cycle times.

Problem-Solving Capabilities: Suppliers with a track record of handling complex projects can troubleshoot issues efficiently, reducing downtime by 15-25%. Request case studies or references to verify their ability to manage challenging projects.

Long-Term Partnership Potential: Building a relationship with a reliable supplier can lead to cost savings over time. Established partners often offer bulk discounts or prioritized scheduling, reducing costs by 5-15% for repeat orders.

Pricing Structure and Transparency

A transparent pricing structure helps avoid hidden costs and ensures cost-effective decisions. Evaluate the supplier’s pricing model to align with your budget.

Cost Breakdown: Request detailed quotes covering material, labor, setup, and additional fees (e.g., expedited shipping). Transparent pricing can reduce total costs by 5-10% by eliminating surprises.

Volume Discounts: Suppliers offering discounts for high-volume orders can lower per-unit costs by 10-20%. For example, producing 1,000 parts instead of 100 can reduce costs per part by 15% due to economies of scale.

Cost vs. Quality: Avoid choosing suppliers based solely on low prices, as this may compromise quality. Low-cost providers may use outdated equipment or skip QC steps, leading to defects and rework costs of 20-30%. Instead, prioritize value by selecting suppliers with competitive pricing and proven quality.

Geographic Considerations: Suppliers in regions with lower labor costs, such as parts of Asia, can offer 10-20% cost savings. However, factor in shipping costs and lead times, which can add 5-15% to expenses for international suppliers.

Key Cost Control Factors Summary

| Фактор | Cost Impact | Cost-Saving Strategy |

|---|---|---|

| Выбор материала | 10-50% of total cost | Use cost-effective materials like aluminum; optimize material usage |

| Оптимизация дизайна | 15-40% cost reduction | Simplify geometries, set realistic tolerances, use DFM |

| Production Efficiency | 10-30% cost reduction | Choose suppliers with modern equipment and automation |

| Контроль качества | 5-25% cost impact | Balance inspection frequency with SPC; ensure certifications |

| Supplier Expertise | 10-25% cost savings | Select experienced providers with industry knowledge |

| Pricing Structure | 5-20% cost variation | Seek transparent pricing and volume discounts |

Заключение

Effective cost control when selecting a CNC service provider requires a systematic approach to material selection, design optimization, production efficiency, quality control, supplier expertise, and pricing transparency. By carefully evaluating these factors, manufacturers can reduce costs by 10-40% while ensuring high-quality parts. Collaborate with suppliers early, verify their capabilities, and prioritize value over the lowest price to achieve long-term cost savings and reliable outcomes.