This article provides a comprehensive, technical analysis of impeller prototypes, focusing on their structural design, material selection, and performance characteristics. Impellers are critical components in turbomachinery, such as centrifugal pumps, compressors, and turbines, where they transfer mechanical energy to fluids to achieve desired flow and pressure. The following sections detail the key aspects of impeller prototypes, supported by precise parameters and empirical insights, ensuring a professional and systematic presentation for engineers and industry professionals.

Impeller Structure

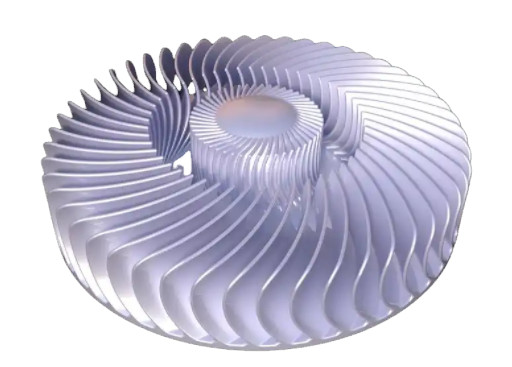

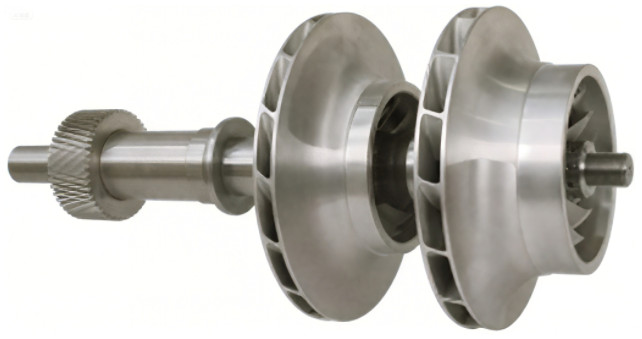

The structural design of an impeller determines its ability to handle fluid dynamics, mechanical stresses, and operational efficiency. Impellers are rotating components with blades or vanes that impart energy to the fluid. Their geometry, including blade shape, number, and orientation, significantly influences performance. The primary structural types include open, semi-open, and closed impellers, each suited for specific applications based on fluid properties and operational requirements.

Open Impellers: These feature blades attached to a central hub without shrouds, allowing easy cleaning and maintenance. They are ideal for handling fluids with suspended solids, such as in wastewater treatment, but exhibit lower efficiency due to fluid recirculation. Typical parameters include a blade number of 4–8 and a diameter range of 100–500 mm, depending on the pump size.

Semi-Open Impellers: These have a single shroud on one side, balancing efficiency and solids-handling capability. They are used in applications like chemical processing, where moderate solids are present. The shroud reduces tip leakage, improving efficiency by 5–10% compared to open impellers.

Closed Impellers: Featuring shrouds on both sides, closed impellers offer the highest efficiency (up to 85–90%) by minimizing leakage losses. They are common in clean fluid applications, such as water supply systems, but are less tolerant of solids. Key parameters include an impeller width of 5–20 mm and a blade wrap angle of 60–120°.

Structural parameters, such as impeller diameter (D2), blade outlet width (b2), and blade wrap angle (φ), are critical. For example, a centrifugal pump impeller with D2 = 166 mm, b2 = 8 mm, and φ = 70° can achieve a head of 20–30 m at 1500 rpm. The number of blades (Z) typically ranges from 4 to 8, with higher numbers improving pressure generation but increasing friction losses.

Computational Fluid Dynamics (CFD) simulations, using tools like ANSYS Fluent, are employed to optimize impeller geometry. For instance, a Rushton turbine impeller with a blade pitch angle of 45° generates radial flow patterns, achieving a flow number (NQ) of 0.7–0.9, indicating efficient pumping capacity. These simulations also reveal velocity vectors and pressure distributions, ensuring uniform fluid mixing.

Выбор материала

Material selection for impeller prototypes is driven by operational conditions, including fluid corrosiveness, temperature, and mechanical stresses. The chosen material must balance strength, durability, and cost while resisting wear, corrosion, and cavitation damage. Common materials include metals, polymers, and composites, each with distinct properties.

Metallic Materials: Stainless steel (e.g., AISI 316, 17-4 PH) is widely used due to its corrosion resistance and high strength. For example, 17-4 PH stainless steel, with a yield strength of 1100 MPa, is suitable for high-speed pumps generating heads up to 6000 ft per stage. Titanium alloys, with a density of 4500 kg/m³ and tensile strength of 900–1200 MPa, are preferred for aerospace and marine applications due to their lightweight and corrosion-resistant properties. Bronze and brass are used in less demanding applications, offering good machinability and moderate corrosion resistance.

Polymeric Materials: Thermoplastics like acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) are used for low-cost prototypes. ABS, with a tensile strength of 40–50 MPa, is favored for pump impellers in non-corrosive environments. Polyether ether ketone (PEEK), with a melting point of 343°C, is suitable for high-temperature applications up to 100°C. However, polymers exhibit higher creep under sustained loads, limiting their use in high-stress environments.

Composite Materials: Polymer composites, such as PEEK-GF30 (30% glass fiber-reinforced PEEK), offer enhanced strength (tensile strength of 150 MPa) and reduced weight compared to metals. They are used in specialized applications, such as medical blood pumps, where precise flow control is critical. Composites also reduce inertia, improving dynamic response in high-speed systems.

The following table summarizes key material properties for impeller applications:

| Материал | Плотность (кг/м³) | Прочность на разрыв (МПа) | Устойчивость к коррозии | Typical Application |

|---|---|---|---|---|

| Stainless Steel (17-4 PH) | 7800 | 1100 | Высокий | High-speed pumps |

| Титановый сплав | 4500 | 900-1200 | Превосходно | Aerospace, marine |

| ABS | 1050 | 40–50 | Умеренный | Prototype pumps |

| PEEK-GF30 | 1500 | 150 | Высокий | Medical pumps |

Material selection also considers manufacturing processes. Investment casting, used for stainless steel impellers, achieves high precision with surface roughness of 0.025 mm. Additive manufacturing, suitable for PLA and ABS, enables rapid prototyping but may introduce porosity, affecting fatigue life.

Performance Characteristics

Impeller performance is evaluated through hydraulic efficiency, head generation, flow rate, and resistance to cavitation. These parameters are influenced by structural design, material properties, and operating conditions, such as rotational speed and fluid viscosity. Performance testing often combines experimental measurements and CFD simulations to validate designs.

Hydraulic Efficiency: Efficiency is defined as the ratio of hydraulic power output to mechanical power input. Closed impellers achieve efficiencies of 85–90%, while open impellers range from 70–80%. Efficiency depends on impeller width and blade angle. For example, increasing blade outlet width from 8 mm to 12 mm can enhance flow rate by 15% but may reduce efficiency by 5% due to increased friction losses.

Head and Flow Rate: Head is the energy imparted to the fluid per unit weight, typically measured in meters. A self-priming pump with an impeller diameter of 166 mm and 6 blades at 1500 rpm can generate a head of 25–35 m. Flow rate, measured in m³/h, is proportional to impeller diameter and speed. For instance, a 200 mm diameter impeller at 3000 rpm delivers a flow rate of 50–100 m³/h.

Cavitation Resistance: Cavitation occurs when low-pressure regions form vapor bubbles, leading to performance degradation and material erosion. The Net Positive Suction Head Required (NPSHR) is a critical parameter, typically 2–5 m for centrifugal pumps. Рабочие колеса with rounded blade edges and optimized inlet angles (e.g., 15–20°) reduce cavitation risk. CFD simulations using SimScale can predict cavitation by analyzing pressure distributions and NPSHR values.

Operational Parameters: Performance is sensitive to rotational speed (500–5000 rpm) and fluid properties. High-viscosity fluids (e.g., 0.01 kg/m·s) require more power, reducing efficiency by 10–20%. Temperature affects viscosity; a 50°C increase can lower viscosity by 30%, improving flow but increasing cavitation risk.

The following table presents performance parameters for a centrifugal pump impeller:

| Параметр | Value | Impact |

|---|---|---|

| Impeller Diameter (D2) | 166 mm | Increases flow rate and head |

| Blade Outlet Width (b2) | 8 mm | Controls flow capacity |

| Blade Wrap Angle (φ) | 70° | Affects pressure generation |

| Скорость вращения | 1500 rpm | Enhances head and flow rate |

Testing involves physical models and numerical simulations. For example, a water model with a PLA impeller at 300 rpm and a gas flow rate of 10 dm³/min achieves uniform gas bubble dispersion, validating refining performance. Flow-3D simulations confirm these results, showing velocity fields and bubble trajectories.

Заключение

Impeller prototypes are defined by their structural design, material properties, and performance characteristics. Open, semi-open, and closed impellers cater to diverse applications, with parameters like diameter, blade width, and wrap angle dictating efficiency and flow. Materials such as stainless steel, titanium, and composites address corrosion, strength, and weight requirements. Performance metrics, including efficiency, head, and cavitation resistance, are optimized through precise design and testing. By integrating empirical data and CFD simulations, engineers can develop reliable impeller prototypes tailored to industrial needs.