Наш блог

Последние статьи

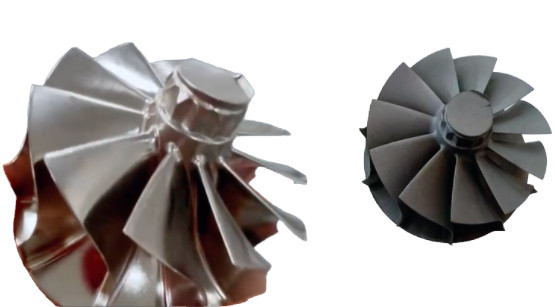

Optimization Steps for High-Temperature Alloy Impeller Polishing Process

A comprehensive guide to optimizing the polishing process for high-temperature alloy impellers, detailing steps, parameters, and technical considerations for achieving superior surface quality.

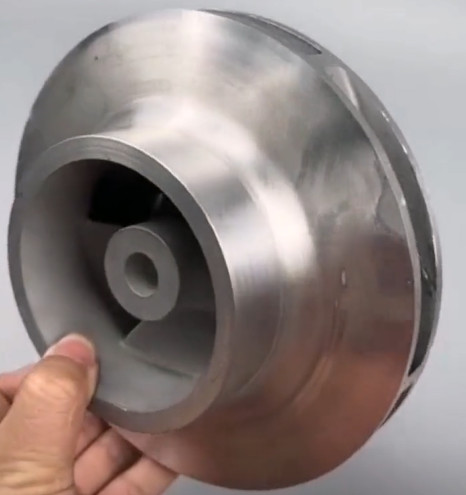

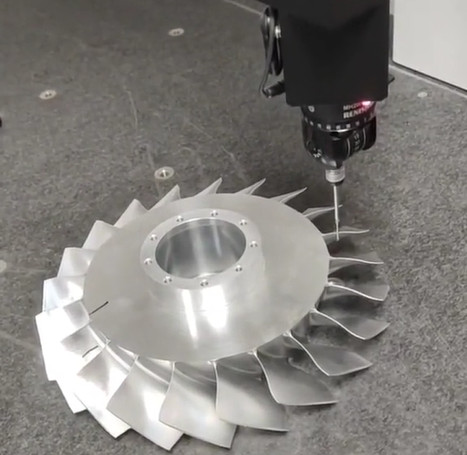

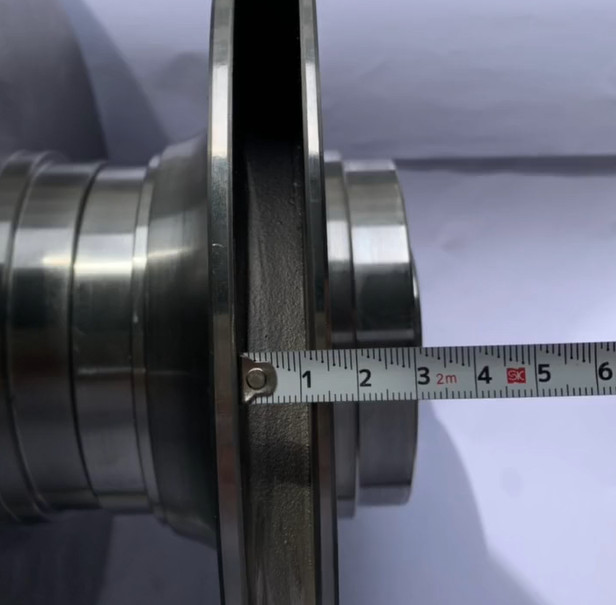

Controlling Concentricity Error to 0.002mm in Impeller Machining

Detailed guide on controlling concentricity error to 0.002mm in impeller machining, covering material selection, tooling, machining strategies, and inspection methods.

Precision Comparison: Laser Sintering vs. Traditional Casting for Stainless Steel Impellers

A detailed comparison of precision in laser sintering (DMLS) and traditional casting for stainless steel impellers, focusing on dimensional accuracy, surface finish, and mechanical properties.

Coating Tool Selection and Efficiency Analysis for Aluminum Alloy Impellers

Comprehensive analysis of coating tool selection and efficiency for machining aluminum alloy impellers, focusing on technical parameters, performance, and practical considerations.

Addressing Thermal Deformation in High-Speed Cutting of Titanium Alloy Impellers

Comprehensive guide on addressing thermal deformation in high-speed cutting of titanium alloy impellers, focusing on technical solutions, parameters, and systematic approaches.

Four Key Control Points in the 3D Printing Process for Centrifugal Impellers

Detailed guide on the four key control points in the 3D printing process for centrifugal impellers, including material selection, design optimization, printing parameters, and post-processing.

Adjusting CNC Machining Parameters for Ra0.05 Surface Finish on Molecular Pump Impellers

Detailed guide on adjusting CNC machining parameters to achieve Ra0.05 surface finish for molecular pump impellers, focusing on technical precision and professional execution.

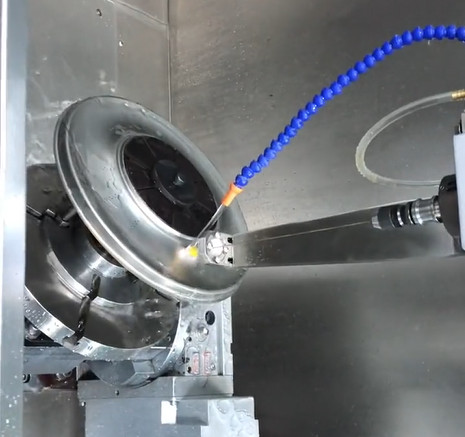

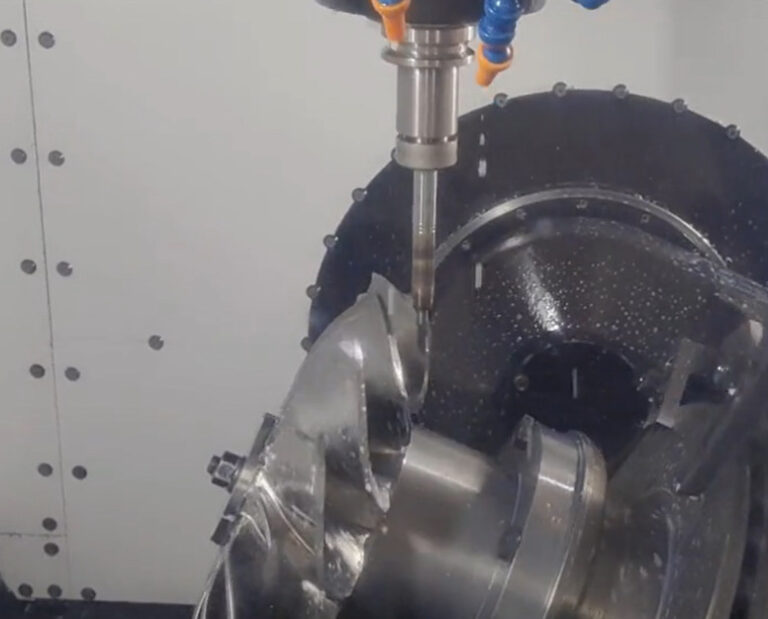

Optimization Study of Five-Axis Cutting Parameters for Turbine Impellers on Swiss Mikron Machines

A comprehensive study on optimizing five-axis cutting parameters for turbine impellers using Swiss Mikron machines, focusing on technical precision and efficiency.

Comparison of Electrical Discharge Machining and Grinding Efficiency for Compressor Impeller Manufacturing

A detailed comparison of Electrical Discharge Machining (EDM) and grinding for compressor impeller manufacturing, focusing on efficiency, precision, and material removal rates.

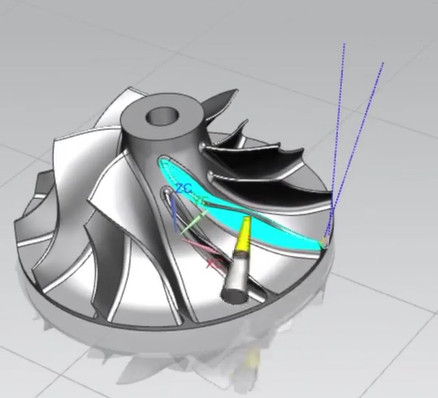

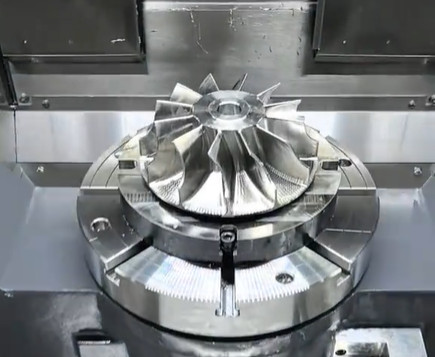

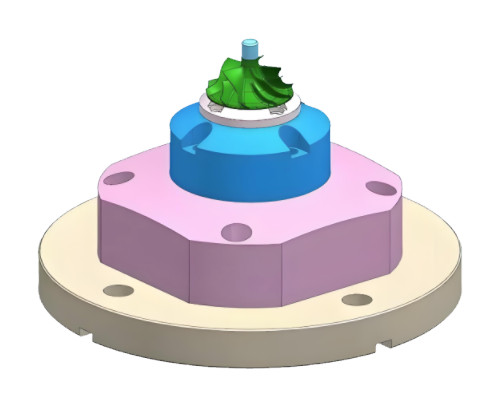

Optimizing Impeller Contour Accuracy to 0.006mm Using Five-Axis Machining

A detailed guide on optimizing impeller contour accuracy to 0.006mm using five-axis machining, covering toolpath planning, machine calibration, tool selection, and error compensation techniques.

Causes and Solutions for Residual Stress in Nickel-Based Alloy Impeller Machining

Comprehensive guide on the causes of residual stress in machining nickel-based alloy impellers and practical solutions to mitigate them, focusing on technical and systematic approaches.

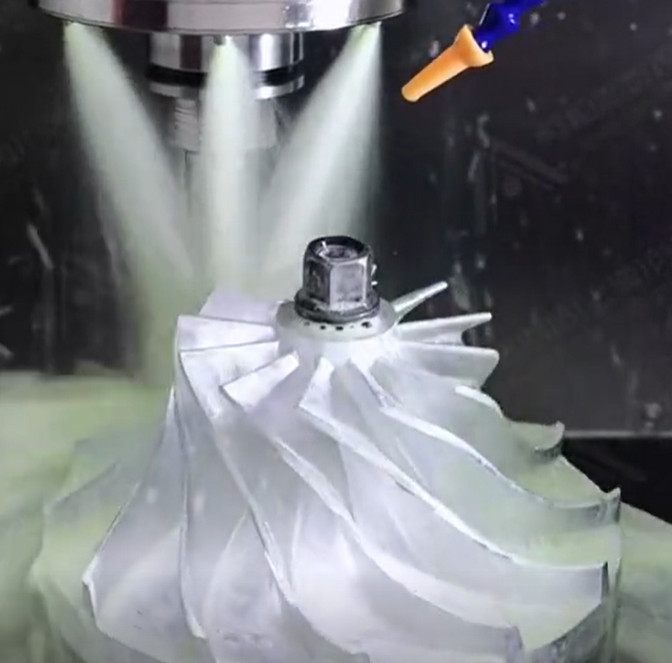

Optimizing Complex Surface Machining of Impellers with Swiss Mikron Five-Axis Machines

A comprehensive guide on optimizing complex surface machining of impellers using Swiss Mikron five-axis machines, focusing on technical strategies, parameters, and practical implementation.

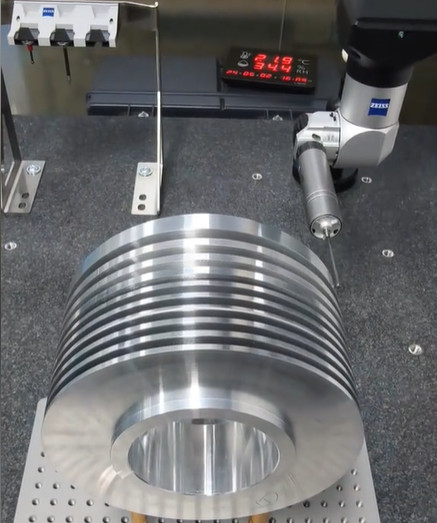

Ensuring Roundness of Vacuum Pump Blades Using Coordinate Measuring Machines

Detailed guide on ensuring roundness of vacuum pump blades using Coordinate Measuring Machines (CMM). Learn the principles, setup, measurement techniques, and analysis methods for high-precision

Heat Treatment and Strength Optimization of Titanium Alloy Impellers

Detailed exploration of heat treatment processes for optimizing the strength of titanium alloy impellers, focusing on technical parameters and systematic approaches.

How Centrifugal Impellers Address Uneven Layer Thickness in 3D Printing

Detailed technical analysis of how centrifugal impellers address uneven layer thickness in 3D printing, focusing on process parameters, material selection, and manufacturing techniques.

Optimizing Machining Precision for Turbine Blades in Turbine Engines

Comprehensive guide on optimizing machining precision for turbine blades in turbine engines, covering methods, parameters, and techniques for enhanced accuracy and performance.

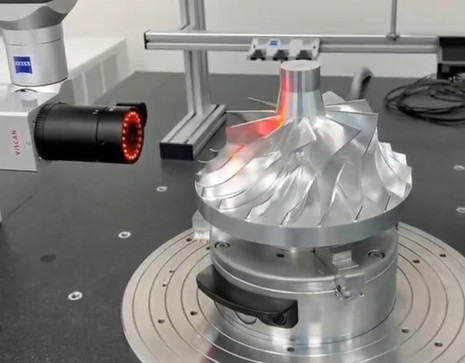

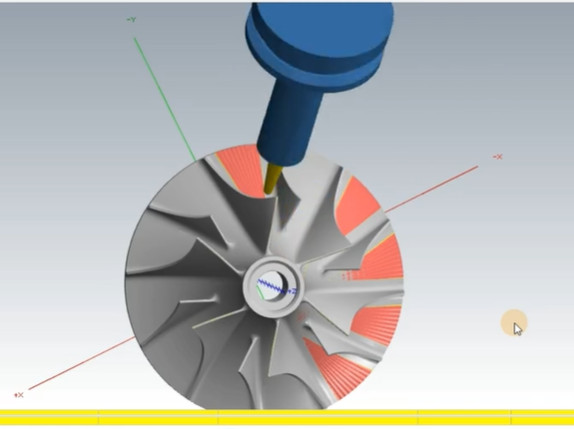

Optimizing ZEISS 3D Inspection for Molecular Pump Impeller Measurement Efficiency

Comprehensive guide on optimizing ZEISS 3D inspection for molecular pump impeller measurement efficiency, focusing on technical setup, calibration, software utilization, and data analysis.

Three Key Processing Techniques to Enhance High-Temperature Resistance of Compressor Impellers

Learn three critical processing techniques to improve the high-temperature resistance of compressor impellers, with detailed parameters and practical insights for engineers and manufacturers.

Mastercam vs. UG Programming for Hastelloy Impeller Manufacturing

A detailed comparison of Mastercam and UG (NX) programming for CNC machining of Hastelloy impellers, focusing on technical aspects, toolpath strategies, and practical considerations.

Addressing Fixture Errors in Aero-Engine Turbine Blade Machining

Comprehensive guide on addressing fixture errors in aero-engine turbine blade machining, focusing on technical solutions, parameters, and systematic approaches.

Optimization Steps for Micro-Arc Oxidation Process of High-Temperature Alloy Impellers

Detailed steps for optimizing the micro-arc oxidation process for high-temperature alloy impellers, focusing on technical parameters and systematic approaches for enhanced coating performance.

How to Control Impeller Machining True Profile Error to 0.007mm

Comprehensive guide on how to control impeller machining true profile error to 0.007mm, detailing precision techniques, equipment, and quality control processes.

Comparison of Polishing and Sandblasting Efficiency for Stainless Steel Impellers

A comprehensive comparison of polishing and sandblasting processes for stainless steel impellers, focusing on efficiency, surface quality, and practical applications.

Tool Selection and Durability Analysis for High-Speed Cutting of Aluminum Alloy Impellers

A comprehensive guide to tool selection and durability analysis for high-speed cutting of aluminum alloy impellers, focusing on technical parameters, material properties, and machining strategies.