Centrifugal impellers are critical components in turbomachinery, such as pumps and compressors, designed to transfer energy from a motor to a fluid, increasing its velocity and pressure. This article provides a detailed examination of their structure, function, applications, and key design parameters, emphasizing technical precision and practical insights for engineers and industry professionals.

Structure of Centrifugal Impellers

A centrifugal impeller is a rotating component, typically disk-shaped, with curved blades or vanes that accelerate fluid radially outward. The impeller’s design directly influences its performance, efficiency, and suitability for specific applications. Key structural elements include:

- Impeller Eye: The central inlet where fluid enters axially.

- Vanes/Blades: Curved surfaces that impart energy to the fluid, typically arranged radially or with backward/forward curvature.

- Hub: The central part connecting the impeller to the drive shaft.

- Shroud: Optional plates enclosing the vanes, present in closed or semi-open impellers.

Impellers are classified into three main types based on their structural design:

| Impeller Type | Описание | Structural Features |

|---|---|---|

| Open | Vanes without enclosing shrouds, mounted on a hub. | Simple design, lower strength, easier to maintain, suitable for small pumps or solids-handling applications. |

| Semi-Open | Vanes with a single shroud on the back side. | Moderate strength, balances efficiency and solids-handling capability, used in medium-sized pumps. |

| Closed | Vanes enclosed between two shrouds. | High strength, high efficiency, complex manufacturing, ideal for clean fluids and large pumps. |

Material selection is critical, with common choices including stainless steel for corrosion resistance, aluminum for lightweight applications, and titanium for high-strength, high-speed scenarios. Material properties must align with the operating environment to prevent wear, corrosion, or cavitation damage.

Function of Centrifugal Impellers

The primary function of a centrifugal impeller is to convert mechanical energy from a motor into kinetic energy in the fluid, which is then transformed into pressure energy as the fluid exits the impeller. This process relies on fundamental fluid dynamics principles, including Bernoulli’s equation and Euler’s turbomachinery equation.

Operational Mechanism:

- Fluid enters the impeller eye axially and is captured by the rotating vanes.

- Centrifugal force accelerates the fluid radially outward, increasing its velocity.

- The fluid exits the impeller into a volute or diffuser, where kinetic energy is converted to static pressure.

Key Performance Parameters:

- Flow Coefficient (φ): A dimensionless parameter defined as φ = Q / (N * D³), where Q is the volumetric flow rate, N is rotational speed, and D is impeller diameter. Typical values range from 0.01 to 0.22 for centrifugal compressors.

- Head Coefficient (ψ): Defined as ψ = gH / (N² * D²), where H is the head generated and g is gravitational acceleration. Typical values are 0.4–0.6 for optimal designs.

- Efficiency (η): The ratio of hydraulic power output to mechanical power input, often 80–90% for well-designed impellers.

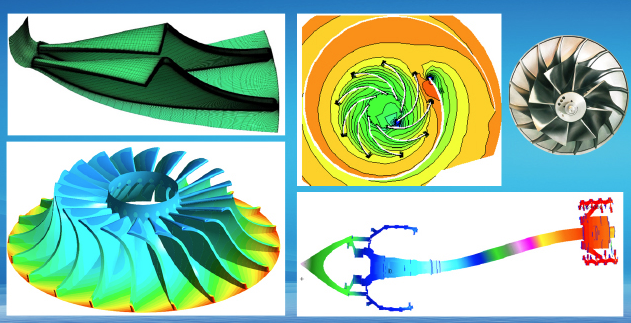

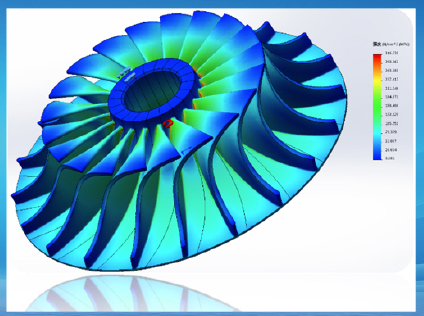

Failure Modes: Common issues include cavitation (vapor bubble formation at low-pressure regions), wear due to abrasive fluids, and imbalance causing vibrations. These can reduce efficiency and damage the impeller surface. Computational Fluid Dynamics (CFD) simulations, using tools like ANSYS CFX, are employed to predict and mitigate these issues.

Applications of Centrifugal Impellers

Centrifugal impellers are versatile components used across various industries due to their ability to handle diverse fluids and operating conditions. Key applications include:

- Centrifugal Pumps: Used in water supply, irrigation, wastewater treatment, and chemical processing for low-viscosity fluids (0.1–200 cP).

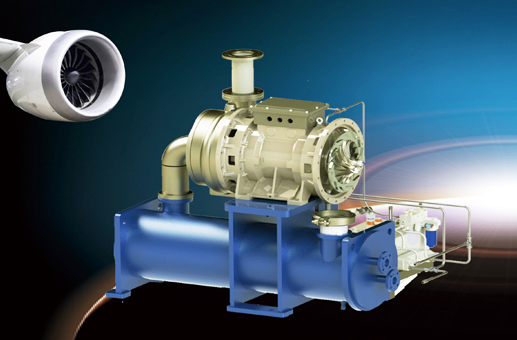

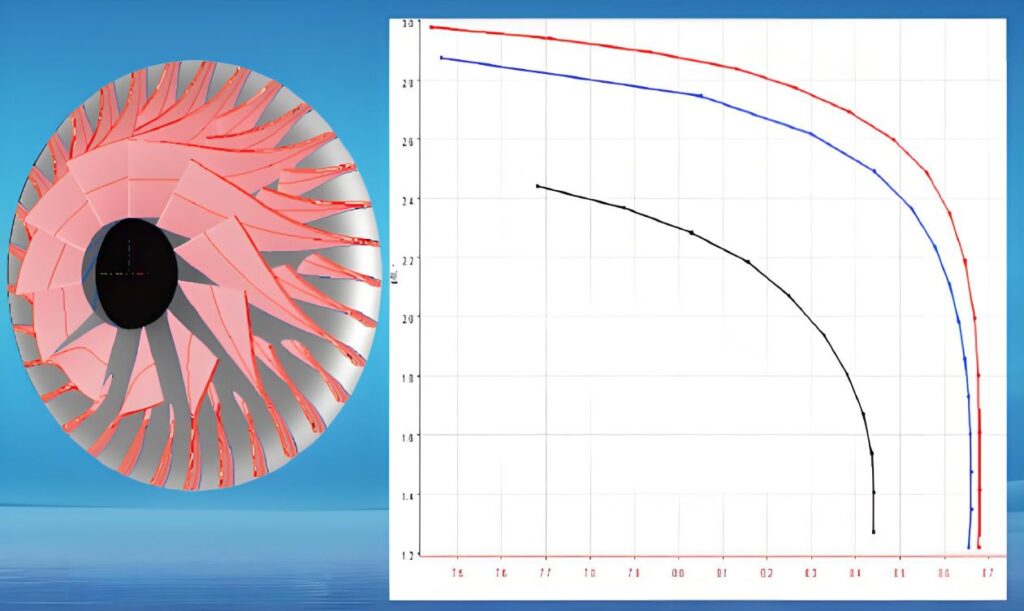

- Centrifugal Compressors: Applied in petrochemical, energy, and marine industries, handling flow rates from 1,000 to 150,000 cfm and pressure ratios up to 3 for single-stage units.

- Fans and Blowers: Employed in HVAC systems, industrial ventilation, and combustion air supply.

- Turbines and Propellers: Used in micro-gas turbines and ship propulsion systems for axial or mixed-flow configurations.

Specific Use Cases:

| Промышленность | Application | Impeller Type | Key Requirements |

|---|---|---|---|

| Wastewater Treatment | Sewage pumping | Open or Vortex | High solids-handling capacity, clog resistance |

| Нефть и газ | Hydrocarbon transfer | Closed | Corrosion resistance, high pressure (up to 100 bar) |

| HVAC | Air circulation | Semi-Open | Low noise, moderate flow rates |

Impellers are tailored to specific applications by adjusting parameters like vane angle, number of blades, and diameter to meet flow, pressure, and efficiency requirements.

Design Parameters and Optimization

The performance of centrifugal impellers depends on several geometric and operational parameters, which are optimized using advanced tools like CFD and machine learning. Key parameters include:

- Impeller Diameter: Larger diameters increase head and flow but require more energy. The affinity law approximates: H ∝ D².

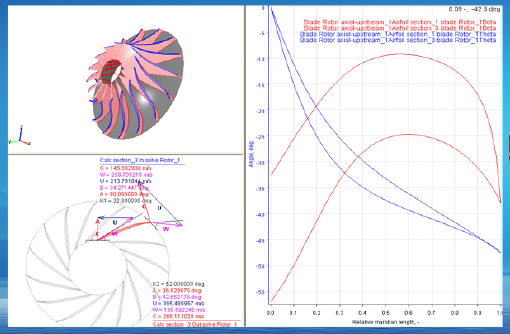

- Blade Angle: Inlet (β₁) and outlet (β₂) angles, typically 15–30° and 20–45°, respectively, affect fluid entry and exit efficiency.

- Number of Blades: Typically 5–12, balancing efficiency and manufacturing complexity.

- Blade Curvature: Backward-curved blades offer higher efficiency, while forward-curved blades provide higher pressure.

Optimization Techniques:

- CFD Simulations: Tools like ANSYS Fluent and CFturbo analyze flow patterns, pressure distribution, and cavitation risks.

- Machine Learning: Artificial neural networks and genetic algorithms optimize geometric parameters for specific flow coefficients (e.g., 0.18–0.22).

- Bezier Surface and FFD: Parameterization techniques enhance blade geometry for improved aerodynamic performance.

Recent studies show that optimized impellers can achieve efficiency improvements of 1–2%, with operating ranges widened by up to 7% through gradient-based algorithms.

Recent Advancements and Research

Recent research focuses on improving impeller performance through advanced design and analysis techniques:

- Manufacturing Uncertainties: Studies address geometric deviations using statistical models and polynomial chaos methods to predict performance variations.

- High-Speed Applications: Impellers operating at 50,000 rpm, such as those with shark fin-like blade designs, are optimized for combustor efficiency.

- Multi-Objective Optimization: Genetic algorithms and response surface methods balance aerodynamic and structural performance.

These advancements underscore the ongoing evolution of impeller design, driven by computational tools and interdisciplinary approaches, ensuring higher efficiency and reliability across diverse applications.

Заключение

Centrifugal impellers are indispensable in turbomachinery, enabling efficient fluid movement across industries like water management, oil and gas, and HVAC. Their performance hinges on precise structural design, material selection, and optimization of parameters like flow and head coefficients. Advances in CFD, machine learning, and manufacturing techniques continue to enhance impeller efficiency and reliability, addressing challenges such as cavitation and wear. By tailoring designs to specific applications and leveraging cutting-edge tools, engineers can maximize performance, reduce energy consumption, and extend operational lifespans, ensuring centrifugal impellers remain a cornerstone of modern fluid dynamics systems.