China has established itself as a global leader in CNC (Computer Numerical Control) machining, offering a wide range of services for industries such as automotive, aerospace, electronics, and medical devices. This guide provides a detailed overview of China’s CNC factories, their capabilities, quality standards, and essential considerations for businesses seeking reliable manufacturing partners. With a focus on technical expertise and systematic processes, this guide aims to help you navigate the landscape of CNC machining in China.

Overview of CNC Machining in China

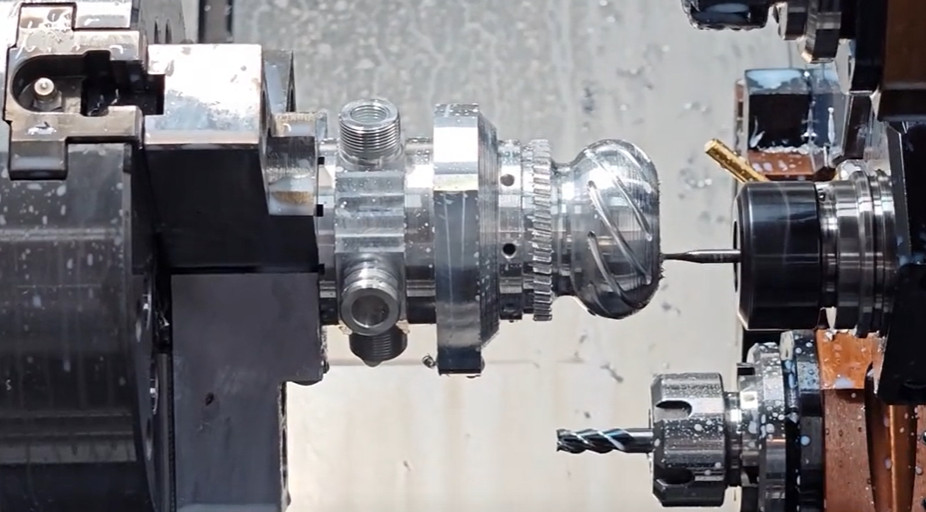

China’s CNC machining industry has grown significantly due to its advanced infrastructure, skilled workforce, and competitive pricing. CNC factories in China provide services such as milling, turning, drilling, and grinding, catering to both prototyping and large-scale production. These factories leverage modern equipment, including 3-axis, 4-axis, and 5-axis CNC machines, to produce high-precision components from various materials like aluminum, stainless steel, titanium, and plastics.

Many Chinese CNC factories operate extensive production facilities, often spanning thousands of square meters and equipped with dozens of advanced CNC machines. For example, some factories feature large vertical gantry mills with work ranges up to 6500 x 4200 x 1800 mm, ensuring versatility in handling complex and oversized parts. These facilities are supported by comprehensive supply chains, enabling efficient production and quick turnaround times.

Key Services Offered by China CNC Factories

China CNC factories provide a broad spectrum of CNC services tailored to meet diverse industry needs. Below is a detailed look at the primary services offered:

- CNC Milling: Utilizes multi-axis machines to create complex geometries with tolerances as tight as ±0.0005 mm. Suitable for producing flat surfaces, slots, and intricate 3D shapes.

- CNC Turning: Employs lathes to produce cylindrical parts with high precision, ideal for components like shafts and fittings.

- CNC Drilling: Focuses on creating precise holes in various materials, often integrated with milling processes for efficiency.

- Surface Finishing: Includes anodizing, powder coating, and polishing to enhance durability and aesthetics.

- Prototyping and Low-Volume Production: Supports rapid prototyping and small-batch production without additional fees, with lead times typically ranging from 20-30 days for short runs.

- Assembly Services: Offers clean assembly and welding to provide complete industrial chain solutions, reducing supply chain complexity.

These CNC services are supported by advanced software for design and simulation, ensuring accuracy and repeatability in production.

Technical Capabilities and Equipment

China CNC factories are equipped with state-of-the-art machinery and technology to meet stringent industry requirements. Key technical capabilities include:

| Тип оборудования | Capabilities | Типовые применения |

|---|---|---|

| Трехкоординатные станки с ЧПУ | Basic milling and turning with tolerances of ±0.01 mm | Simple components, brackets, housings |

| Четырехкоординатные станки с ЧПУ | Rotational milling for complex geometries, tolerances of ±0.005 mm | Gears, impellers, multi-sided parts |

| 5-осевые станки с ЧПУ | Multi-angle machining with tolerances of ±0.0005 mm | Aerospace parts, medical implants, turbine blades |

| Vertical Gantry Mills | Large-scale machining, work range up to 6500 x 4200 x 1800 mm | Automotive frames, large molds |

Factories often integrate IoT and data analytics for real-time process monitoring, improving efficiency and precision. For instance, some facilities collect millions of data points daily to monitor parameters like feed rate and spindle performance, ensuring optimal operation.

Quality Control and Certifications

Quality assurance is a cornerstone of China’s CNC machining industry. Reputable factories adhere to international standards, such as ISO 9001:2015, to ensure consistent product quality. Quality control processes include:

- Precision Metrology: Use of Coordinate Measuring Machines (CMMs) and profile projectors to verify tolerances down to ±0.0005 mm.

- Detailed Inspection Reports: Comprehensive documentation provided with each delivery, outlining dimensional accuracy and material conformity.

- Material Testing: Verification of material properties to meet specifications, including hardness and tensile strength tests.

- Process Monitoring: Real-time data collection to detect deviations during production, ensuring consistency.

Many factories follow ISO 2768 standards for CNC milling, ensuring compatibility with global manufacturing requirements. Certifications like ISO 9001 demonstrate a commitment to quality, giving clients confidence in the reliability of the produced parts.

Material Options and Processing Flexibility

China CNC factories offer a wide range of materials to accommodate various applications. Common materials include:

- Металлы: Aluminum, stainless steel, titanium, brass, and copper, suitable for high-strength and corrosion-resistant components.

- Пластмассы: ABS, POM, and PEEK, ideal for lightweight and chemically resistant parts.

- Specialty Materials: High-temperature alloys and composites for aerospace and medical applications.

Factories can process micro-scale parts or extra-large components, with adjustable work envelopes to accommodate varying production volumes. For example, some facilities handle small-batch orders of fewer than 500 pieces without additional fees, ensuring cost-effectiveness for low-volume production.

Key Considerations for Selecting a CNC Factory

Choosing the right CNC factory in China requires careful evaluation. Below are essential factors to consider:

| Фактор | Описание |

|---|---|

| Manufacturing Experience | Look for factories with over 10 years of experience and a proven track record in your industry. |

| Equipment and Capacity | Ensure the factory has advanced machinery and sufficient capacity for your project’s scale. |

| Quality Certifications | Verify ISO 9001 or similar certifications to ensure adherence to international standards. |

| Communication and Support | Assess responsiveness and technical support, including the ability to provide precision check videos or factory floor details. |

| Lead Time and Pricing | Compare lead times (typically 20-30 days for short runs) and ensure competitive pricing without compromising quality. |

It’s also important to distinguish between manufacturers and trading companies. Manufacturers provide direct technical support and detailed precision checks, while trading companies may lack in-depth expertise. Requesting factory floor images or precision test videos can help verify authenticity.

Supply Chain and Logistics

China CNC factories often manage robust supply chains, integrating raw material procurement, machining, and surface treatment to streamline production. Many offer door-to-door delivery China CNC services, with products exported to over 150 countries. Factories located near major transport hubs, such as Shanghai or Anhui, benefit from efficient logistics via high-speed rail or air, reducing delivery times.

For example, factories in Kunshan City, 40 km from Shanghai, leverage proximity to ports and railways to expedite shipping. Typical lead times for short-run production range from 10-30 days, while large-scale orders may take 30-45 days, depending on complexity and volume.

Отраслевые применения

China CNC factories serve a wide range of industries, including:

- Автомобиль: Produces precision components like engine parts and transmission gears, meeting high performance standards for fuel efficiency and durability.

- Аэрокосмическая промышленность: Manufactures complex parts like landing gears, рабочие колеса, and turbine blades, requiring high-torque machining and tight tolerances.

- Electronics: Creates housings, connectors, and heat sinks with fine surface finishes.

- Medical Devices: Produces implants and surgical tools with biocompatible materials like titanium and PEEK.

Factories often tailor their services to meet industry-specific requirements, such as high-temperature alloy machining for aerospace or clean assembly for medical applications.

Cost-Effectiveness and Competitive Advantage

One of the primary advantages of partnering with China CNC factories is cost-effectiveness. For instance, CNC milling services in China can be up to 50% lower than those in Europe or North America, without compromising quality. This is achieved through efficient production processes, large-scale facilities, and competitive labor costs.

Factories also offer flexibility in order sizes, accommodating both prototyping and high-volume production. The ability to provide instant quotes through online platforms, based on uploaded CAD files, further enhances efficiency and transparency in pricing.

Kesu: Precision CNC Machining, Redefined for Global Excellence

Kesu specializes in empowering industries from automotive to aerospace, electronics to medical devices, with precision that sets new standards: think CNC milling and turning with tolerances as strict as ±0.0025 mm, enhanced by 5-axis technology and ISO 9001-certified quality. Whether you need rapid prototyping, small-batch runs, or large-scale production, our advanced facilities deliver—with lead times as short as 7-30 days, cost savings of up to 50% versus Western alternatives, and seamless door-to-door shipping to 150+ nations. At Kesu, we pair cutting-edge machinery with clear communication and rigorous quality checks, turning your CAD designs into flawless, industry-ready components. Choose Kesu: where precision meets efficiency, and every project gets the tailored excellence it deserves.

Заключение

China’s CNC factories offer a compelling combination of advanced technology, comprehensive services, and competitive pricing, making them a preferred choice for global businesses. By understanding their capabilities, quality standards, and key selection criteria, you can identify a reliable partner for your machining needs. Whether you require precision prototyping or large-scale production, China’s CNC industry is well-equipped to deliver high-quality components across diverse applications.

FAQ: China CNC Machining Factories

What industries do China CNC factories primarily serve?

China CNC factories cater to a wide range of industries, including automotive (engine parts, transmission gears), aerospace (landing gears, turbine blades, impellers), electronics (housings, connectors), and medical devices (implants, surgical tools). They also support sectors requiring precision components, such as industrial machinery and consumer goods.

What are the key services offered by China CNC factories?

CNC milling (complex 3D geometries with tolerances as tight as ±0.0005 mm)

CNC turning (cylindrical parts like shafts)

CNC drilling (precision hole creation)

Surface finishing (anodizing, powder coating, polishing)

Prototyping, low-volume production, and assembly services (clean assembly, welding).

What factors should businesses consider when selecting a China CNC factory?

Manufacturing experience (10+ years in the target industry).

Equipment and capacity (advanced machinery for project scale).

Quality certifications (ISO 9001, industry-specific accreditations).

Communication/support (responsiveness, technical transparency).

Lead times and pricing (competitive rates without quality compromises).

Why are China CNC factories cost-effective compared to other regions?

Cost advantages stem from efficient large-scale production, competitive labor costs, and integrated supply chains (raw materials to finishing). Services like CNC milling can be up to 50% cheaper than in Europe or North America, with no sacrifice in precision or quality.

What lead times can be expected for production?

Prototyping and low-volume runs (e.g., <500 pieces): Typically 10–30 days.

Large-scale orders: 30–45 days, depending on complexity and volume.