Impeller dynamic balance is essential for the reliable operation of turbines, including centrifugal pumps used as turbines (PATs) and other turbomachinery. When dynamic balance testing indicates that an impeller fails to meet specified balance tolerances, the consequences can include excessive vibrations, reduced efficiency, and mechanical failures. This article provides a systematic, technical analysis of these impacts, supported by detailed parameters and structured insights, focusing on mechanical and hydraulic effects without speculative content. Specific issues, such as increased maintenance costs and downtime, are addressed where relevant.

Principles of Impeller Dynamic Balance

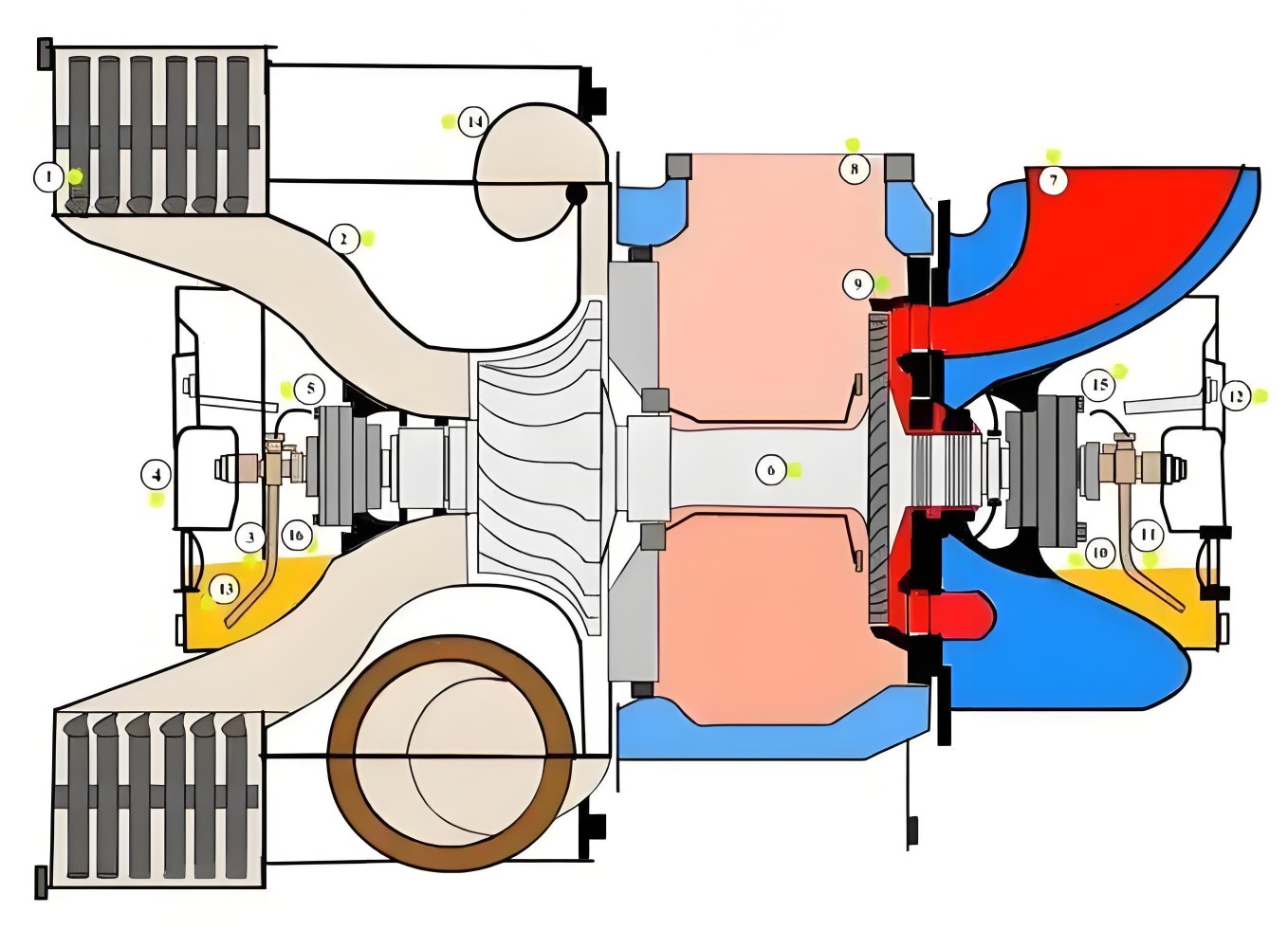

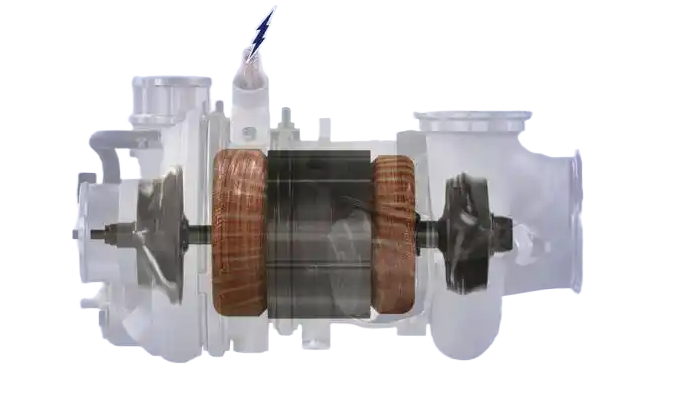

Dynamic balance ensures an impeller’s mass is evenly distributed around its rotational axis to minimize vibrations during operation. In turbines, the impeller converts fluid energy into mechanical energy (or vice versa in pumps), making balance critical for performance. Unqualified dynamic balance testing means the residual unbalance exceeds limits set by standards like ISO 1940-1, which specifies balance quality grades such as G2.5 for turbines operating at 1500–30,000 rpm.

Residual unbalance is measured in gram-millimeters (g-mm). For a 6 kg impeller with a 280 mm diameter operating at 1500 rpm, the permissible residual unbalance is typically 10–20 g-mm to keep vibration levels below 2 mm/s RMS (root mean square). Exceeding these limits leads to operational issues, as detailed below.

Consequences of Unqualified Dynamic Balance

Unqualified dynamic balance testing results in excessive vibrations, hydraulic inefficiencies, and increased mechanical stress, all of which compromise turbine performance. The following sections examine these consequences with technical parameters and system-level considerations, highlighting specific issues where applicable.

Vibration-Induced Mechanical Stress

An unbalanced impeller generates centrifugal forces proportional to the square of the rotational speed, causing vibrations that stress turbine components like bearings, seals, and shafts. For a 6 kg impeller with a 280 mm diameter at 22,918 rpm, a residual unbalance of 5 g-mm can produce forces exceeding 10 kN. These forces cause cyclic loading, accelerating wear and increasing maintenance costs.

Bearings are particularly affected, with vibrations above 5 mm/s RMS reducing their lifespan. A bearing rated for 100,000 hours at 1480 rpm may fail in 40,000–50,000 hours under such conditions, leading to unplanned downtime and repair costs. Vibrations can also loosen mounting bolts, causing misalignment and further structural stress. For example, a vibration amplitude of 4 mm/s RMS can reduce the fatigue life of a steel shaft by 25–35%, necessitating frequent inspections.

Issue: Increased maintenance costs and downtime due to accelerated bearing wear and misalignment, requiring more frequent repairs and inspections.

Loss of Hydraulic Efficiency

An unbalanced impeller disrupts the flow field within the turbine, reducing hydraulic efficiency. In PAT systems, the impeller extracts energy from the fluid. Unbalance causes flow separation and vortices at the impeller inlet, decreasing energy transfer efficiency. Studies indicate a 1–4% efficiency drop at the best efficiency point (BEP), with losses up to 5–7% at off-design conditions (e.g., 0.8–1.2 QBEP).

For a PAT with a flow rate of 500 m³/h and a head of 50 m, an unbalanced impeller may reduce efficiency from 70% to 65%, resulting in a power loss of about 12 kW for a 100 kW system. This inefficiency increases energy consumption, raising operational costs in applications like micro-hydropower or industrial fluid systems.

Issue: Higher energy costs due to reduced efficiency, impacting the economic viability of turbine operations, especially in energy-intensive applications.

Risk of Mechanical Failure

Unbalanced impellers increase the risk of catastrophic failure due to fatigue and stress concentration. For a turbo impeller made of AA 7075 aluminum alloy at 989 kW and 22,918 rpm, unbalance-induced stresses near defects (e.g., a partially drilled hole) can exceed the material’s fatigue limit of 150 MPa, leading to crack initiation. Blade failure can damage the turbine and adjacent systems, causing significant downtime and repair costs.

The table below outlines the relationship between unbalance levels and failure modes:

| Unbalance Level (g-mm) | Vibration Amplitude (mm/s RMS) | Failure Mode | Lifespan Reduction |

|---|---|---|---|

| 10–20 | 2–3 | Bearing wear | 10-20% |

| 20-50 | 3–5 | Seal leakage, shaft misalignment | 20-40% |

| >50 | >5 | Blade fatigue, catastrophic failure | 50-80% |

Issue: Risk of catastrophic failure leading to extensive downtime and high repair costs, particularly in high-speed or high-power turbine systems.

Flow Instability and Pressure Fluctuations

Unbalanced impellers cause unsteady flow patterns, resulting in pressure fluctuations that destabilize turbine operation. In PAT systems without guide vanes, vortices at the impeller inlet can cause pressure fluctuations of 10–15% at 95.23 m³/h and 1500 rpm, compared to 5% for a balanced impeller. These fluctuations increase hydraulic losses and reduce system stability.

Severe pressure fluctuations can induce cavitation, where vapor bubbles collapse near the impeller blades, causing erosion. In turbines with pressure drops exceeding 400 kPa, cavitation can reduce impeller lifespan by 30–50%, particularly for materials like stainless steel or bronze, necessitating frequent replacements.

Causes of Unqualified Dynamic Balance

Several factors contribute to unqualified dynamic balance testing, each with specific technical implications for turbine performance. These are detailed below.

Manufacturing Imperfections

Manufacturing defects, such as uneven material distribution or machining errors, are common causes of impeller unbalance. A partially drilled hole in a turbo impeller can introduce a 5–10 g-mm unbalance, generating vibrations of 3–4 mm/s RMS at 22,918 rpm. Casting imperfections, like porosity or inclusions, can exacerbate unbalance. A 0.1% mass variation (6 g) in a 6 kg impeller at a 140 mm radius results in an 840 g-mm unbalance, exceeding typical tolerances.

Non-destructive testing (e.g., ultrasonic or X-ray inspection) is critical to detect these defects. Inadequate quality control can allow imperfections to persist, leading to operational issues.

Improper Impeller Trimming

Impeller trimming adjusts a PAT’s operating condition to match specific flow and head requirements. Asymmetric trimming can introduce unbalance. Trimming a 255 mm diameter impeller to 215 mm reduces the flow rate by 20 m³/h and efficiency by 2.17% at the BEP. If not performed symmetrically, trimming can increase unbalance by 15–30 g-mm, causing vibrations of 4–6 mm/s RMS and reducing bearing life by 20–30%.

The table below illustrates the impact of trimming on performance:

| Impeller Diameter (mm) | Flow Rate (m³/h) | Efficiency at BEP (%) | Potential Unbalance (g-mm) |

|---|---|---|---|

| 255 | 95.23 | 70.00 | 10–20 |

| 235 | 90.00 | 68.50 | 15–25 |

| 215 | 75.23 | 67.83 | 20–30 |

Operational Wear and Corrosion

Prolonged operation in harsh environments can alter an impeller’s mass distribution. Corrosion in water or oil applications can remove material unevenly, creating an unbalance of 5–15 g-mm. For example, pitting corrosion causing a 0.5% mass loss at the blade edges of a 280 mm diameter impeller can induce vibrations of 2–4 mm/s RMS. Wear in open or semi-open impellers, such as a 1 mm reduction in blade thickness, can increase unbalance by 10 g-mm, reducing efficiency and lifespan.

Mitigation Strategies for Unqualified Dynamic Balance

Addressing unqualified dynamic balance requires rigorous testing, corrective actions, and preventive measures to ensure turbine reliability. The following strategies focus on technical solutions.

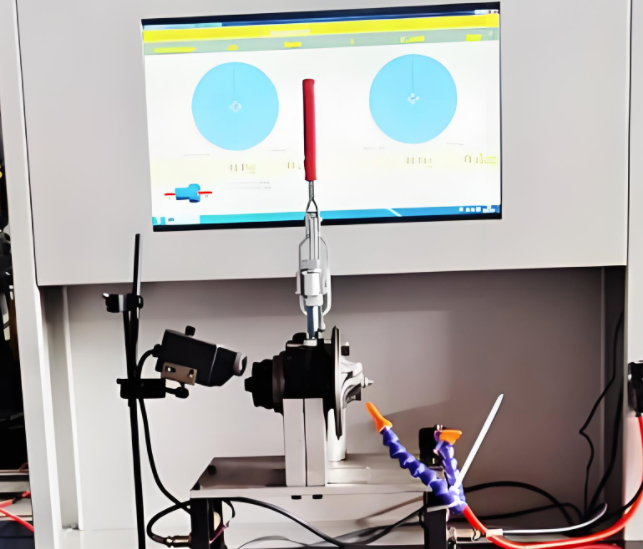

Precision Dynamic Balancing

Dynamic balancing should use high-precision equipment capable of detecting unbalance below 5 g-mm. Two-plane balancing is recommended for complex impeller geometries to address both static and dynamic unbalance. Calibration to ISO 1940-1 standards ensures accuracy. For a 6 kg impeller at 1500 rpm, the target residual unbalance should be below 15 g-mm, maintaining vibrations under 2 mm/s RMS.

Enhanced Manufacturing Quality Control

Stringent quality control during manufacturing can minimize unbalance. Non-destructive testing, such as dye penetrant or ultrasonic inspection, should detect defects like porosity or machining errors. Maintaining dimensional tolerances of ±0.1 mm during casting can limit unbalance to 5 g-mm. Automated machining processes enhance symmetry and reduce errors.

Routine Maintenance and Monitoring

Regular maintenance, including vibration monitoring and impeller inspection, can detect unbalance early. Vibration sensors should measure amplitudes as low as 1 mm/s RMS for early warnings. Periodic cleaning and coating applications can mitigate corrosion, while rebalancing every 12–18 months can maintain performance in harsh environments.

Заключение

Unqualified impeller dynamic balance testing significantly impacts turbine performance, causing excessive vibrations, hydraulic inefficiencies, mechanical failures, and flow instabilities. These issues, driven by manufacturing imperfections, improper trimming, and operational wear, lead to increased maintenance costs, downtime, and energy losses. Precision balancing, enhanced quality control, and routine maintenance can mitigate these effects, ensuring reliable and efficient turbine operation. This technical analysis, supported by specific parameters and structured insights, provides a comprehensive framework for addressing impeller unbalance in turbomachinery.