Quote transparency in CNC machining services is a critical factor that influences procurement decisions, operational efficiency, and long-term supplier relationships. By providing clear, detailed, and accurate cost breakdowns, CNC service providers enable procurement professionals to make informed decisions, optimize budgets, and ensure project success. This article examines the impact of quote transparency on procurement, emphasizing its role in cost management, supplier evaluation, and operational streamlining. The discussion is grounded in technical insights and practical considerations, offering a systematic perspective for procurement managers and engineers in manufacturing industries.

Understanding Quote Transparency in CNC Machining

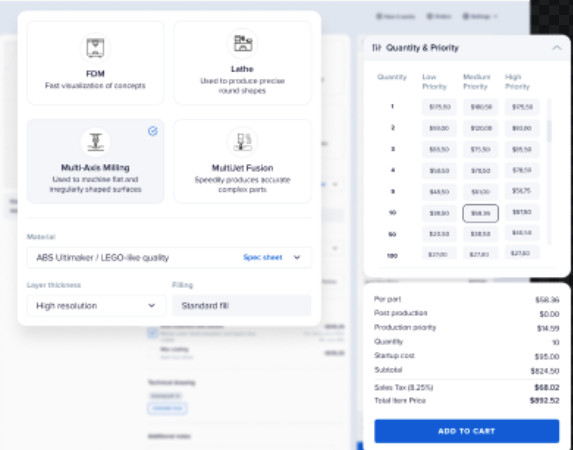

Quote transparency refers to the practice of CNC service providers offering detailed, itemized cost breakdowns in their quotations, including materials, labor, tooling, setup, finishing, and delivery costs. Unlike traditional Request for Quote (RFQ) processes, which often provide limited information, transparent quotes specify the cost drivers and assumptions behind the pricing. This clarity allows buyers to understand the value proposition and assess the feasibility of a supplier's offer.

На сайте Обработка на станках с ЧПУ, quotes typically include parameters such as material type (e.g., aluminum 6061, stainless steel 316), tolerances (e.g., ±0.005 mm), surface finishes (e.g., anodizing, bead blasting), and production volume. A transparent quote will also detail lead times, often ranging from 5 to 30 days depending on complexity, and may include additional services like quality assurance or assembly. For example, a quote for machining a batch of 100 алюминиевые детали with tight tolerances might break down as follows:

| Cost Component | Подробности | Estimated Cost (USD) |

|---|---|---|

| Материал | Aluminum 6061, 100 kg | 500 |

| Labor | 50 hours at $40/hour | 2,000 |

| Инструментальная оснастка | Custom end mill for complex geometry | 300 |

| Настройка | 2 setups at $150 each | 300 |

| Отделка | Anodizing, Type II | 400 |

| Total | - | 3,500 |

Such transparency ensures buyers can evaluate the quote against project requirements and compare it with other suppliers, fostering trust and accountability.

Impact on Cost Management and Budget Optimization

Transparent quotes directly influence cost management by providing procurement teams with a clear understanding of expenses. This clarity enables accurate budgeting and prevents unexpected costs during production. For instance, a transparent quote reveals whether high material costs are due to premium alloys or if labor costs are elevated because of complex geometries requiring extended machining time.

With detailed cost breakdowns, procurement professionals can identify opportunities for cost optimization. For example, if a quote shows high tooling costs due to custom tools, buyers can explore design simplifications to use standard tools, reducing expenses by 10-20% in some cases. Similarly, understanding setup costs encourages batching similar parts to minimize machine setup time, which can account for 5-15% of total costs in small-batch production. Transparent quotes also allow buyers to negotiate specific cost components, such as switching from stainless steel 316 to 304 to save 15-25% on material costs without compromising functionality.

Moreover, transparency reduces the risk of hidden costs, such as expedited shipping fees or additional quality checks, which can inflate budgets by up to 10% if not disclosed upfront. By aligning quotes with project budgets, procurement teams can allocate resources efficiently, ensuring projects remain financially viable.

Enhancing Supplier Evaluation and Selection

Quote transparency plays a pivotal role in supplier evaluation by providing a standardized basis for comparison. In traditional RFQ processes, quotes often vary in format and detail, making it difficult to assess suppliers objectively. Transparent quotes, however, include consistent parameters such as material grades, machining tolerances, and lead times, enabling procurement teams to evaluate suppliers based on capability and cost-effectiveness.

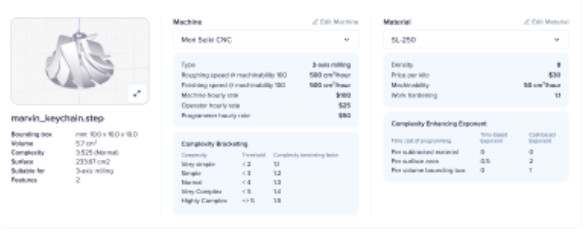

For example, when comparing quotes for a part requiring ±0.01 mm tolerances, a transparent quote will specify whether the supplier uses 5-axis CNC machines capable of achieving such precision. This information helps buyers verify if the supplier’s equipment, such as vertical machining centers (VMCs) with high-speed spindles (e.g., 12,000 RPM), aligns with project needs. Additionally, transparent quotes reveal quality assurance processes, such as whether suppliers use coordinate measuring machines (CMMs) for inspection, ensuring compliance with specifications.

Transparency also fosters trust in supplier relationships. Suppliers who provide detailed quotes demonstrate confidence in their pricing and capabilities, reducing the likelihood of disputes over cost overruns. This trust is critical for long-term partnerships, where procurement teams rely on suppliers for consistent quality and delivery. For instance, a supplier offering a transparent quote with a 7-day lead time for 500 parts signals reliability, compared to a vague quote with no clear timeline.

Streamlining Procurement Operations

Transparent quotes streamline procurement operations by reducing the time and effort required for decision-making. In traditional RFQ processes, procurement teams may spend days or weeks clarifying vague quotes, requesting additional details, or resolving discrepancies. Transparent quotes eliminate these inefficiencies by providing all necessary information upfront, such as material certifications, machining processes (e.g., milling, turning), and delivery schedules.

Для complex projects, transparency facilitates collaboration between procurement, engineering, and quality assurance teams. For example, a quote detailing the use of geometric dimensioning and tolerancing (GD&T) allows engineers to confirm that the supplier can meet design specifications, reducing the risk of rework, which can cost 5-10% of the project budget. Similarly, clear lead time estimates enable procurement teams to align production schedules, avoiding delays that could extend project timelines by 10-20%.

Transparent quotes also support digital procurement platforms, where standardized data formats enable automated quote comparisons. For instance, a platform like Contracts Finder in the UK allows buyers to upload detailed RFQs and receive standardized quotes, reducing evaluation time by up to 30%. This efficiency is particularly valuable for high-volume procurement, where processing multiple quotes manually can overwhelm procurement teams.

Building Trust and Accountability

Transparency in quotes fosters trust and accountability between CNC service providers and buyers. By openly sharing cost breakdowns and production assumptions, suppliers signal their commitment to fair pricing and quality delivery. This openness reduces the perception of risk for buyers, who may otherwise suspect hidden costs or inflated margins.

For instance, a supplier providing a detailed quote that includes material traceability (e.g., compliance with ASTM standards) reassures buyers that the parts meet regulatory requirements, critical in industries like aerospace or medical device manufacturing. Similarly, transparency in labor costs, such as specifying 20 hours of CNC programming at $50/hour, demonstrates accountability for the quoted price.

Accountability extends to ethical considerations, such as disclosing sourcing practices for raw materials. For example, a transparent quote might confirm that materials are free from conflict minerals, aligning with regulations like the Dodd-Frank Act. This transparency not only ensures compliance but also enhances the buyer’s reputation for ethical procurement practices.

Facilitating Long-Term Supplier Relationships

Transparent quotes lay the foundation for long-term supplier relationships by fostering mutual understanding and collaboration. When suppliers provide detailed cost breakdowns, buyers gain insight into the supplier’s processes, enabling them to propose design or production optimizations that benefit both parties. For example, a buyer might suggest reducing the number of setups from three to two, cutting costs by 10% while maintaining quality.

Long-term relationships also benefit from transparent communication about production capabilities. A supplier who discloses limitations, such as a maximum part size of 500 mm due to machine constraints, helps buyers avoid mismatched expectations. This honesty encourages repeat business, as buyers prefer suppliers who consistently deliver predictable outcomes.

Furthermore, transparent quotes enable performance tracking over multiple projects. By maintaining records of past quotes, procurement teams can evaluate supplier reliability, such as whether lead times of 10-15 days were consistently met. This data-driven approach strengthens partnerships, as both parties can address inefficiencies and align on future projects.

Practical Considerations for Implementing Quote Transparency

To maximize the benefits of quote transparency, procurement teams and CNC service providers must adopt practical strategies. Buyers should request standardized quote formats that include key parameters like material specifications, tolerances, and lead times. Suppliers, in turn, should invest in systems to generate detailed quotes efficiently, such as ERP software that integrates cost data from material suppliers and machine logs.

Collaboration is also essential. Procurement teams should engage suppliers early in the RFQ process to clarify requirements, reducing the likelihood of vague or incomplete quotes. For example, providing CAD files in STEP or IGES format ensures suppliers can accurately assess machining complexity, leading to more precise quotes.

Finally, both parties should prioritize clear communication. Suppliers should proactively explain cost drivers, such as why a specific alloy increases material costs by 20%. Buyers should provide feedback on quotes to refine future submissions, creating a cycle of continuous improvement.

Заключение

Quote transparency from CNC service providers significantly impacts procurement by enhancing cost management, supplier evaluation, operational efficiency, trust, and long-term relationships. Detailed quotes with clear cost breakdowns, technical specifications, and delivery timelines empower procurement teams to make informed decisions, optimize budgets, and streamline operations. By fostering accountability and collaboration, transparency strengthens supplier partnerships, ensuring consistent quality and reliability. For procurement professionals and CNC service providers alike, prioritizing transparency is a strategic approach to achieving successful outcomes in manufacturing projects.