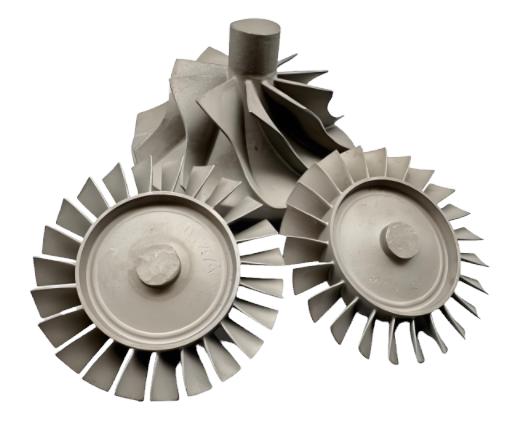

Titanium alloy impellers are critical components in industries such as aerospace, petrochemical, and energy, valued for their high strength-to-weight ratio and corrosion resistance. However, their surface treatment presents significant challenges due to the material’s unique properties, including low thermal conductivity, high chemical reactivity, and susceptibility to surface defects. This article provides a detailed, technical guide on how to solve common surface treatment issues for titanium alloy impellers, focusing on practical solutions, precise parameters, and systematic approaches to ensure high-quality outcomes.

Understanding Titanium Alloy Impeller Surface Treatment

Surface treatment of titanium alloy impellers is essential to enhance their performance, durability, and resistance to environmental factors. The process typically involves cleaning, acid pickling, mechanical polishing, or coating to remove defects, improve surface smoothness, and ensure compatibility with operational conditions. Common issues during surface treatment include over-corrosion, residual oxide scale, surface contamination, and uneven surface finish. These problems can compromise the impeller’s aerodynamic performance and mechanical efficiency. The following sections detail these issues and their respective solutions, supported by technical parameters and professional methodologies.

Common Surface Treatment Issues and Solutions

Over-Corrosion During Acid Pickling

Over-corrosion occurs when the titanium alloy surface develops pitting or uneven texture during acid pickling, often due to improper acid composition or prolonged exposure. This defect degrades surface integrity and can lead to stress concentration points, reducing the impeller’s fatigue life.

Solution: Optimize the acid pickling process by controlling the acid composition and pickling duration. A typical pickling solution for titanium alloys consists of hydrofluoric acid (HF) and nitric acid (HNO₃) in a specific ratio. The recommended concentration is 2-4% HF and 20-40% HNO₃, with water as the balance. The pickling time should range from 1 to 4 minutes, depending on the impeller’s size and surface condition. Monitor the bath temperature, keeping it below 40°C to prevent excessive etching. Regular testing of the acid solution’s pH and concentration ensures consistency. After pickling, rinse the impeller thoroughly with deionized water to remove residual acid and prevent further corrosion.

Residual Oxide Scale

Oxide scale, formed during high-temperature processing or machining, can remain on the impeller surface if not properly removed. This defect affects surface smoothness and may cause adhesion issues during subsequent coating processes.

Solution: Employ a combination of mechanical and chemical methods to remove oxide scale. Start with abrasive blasting using aluminum oxide or glass beads at a pressure of 0.2-0.4 MPa to dislodge loose scale. Follow this with acid pickling using the aforementioned HF-HNO₃ solution to dissolve remaining oxides. For stubborn scale, a two-step pickling process may be necessary: an initial pickling with a higher HF concentration (5-7%) for 30-60 seconds, followed by a standard pickling cycle. Ensure proper ventilation and safety measures during handling of hazardous chemicals. Post-treatment inspection using a magnifying lens or surface profilometer confirms complete scale removal.

Surface Contamination (Hanging Ash)

Surface contamination, often referred to as “hanging ash,” manifests as a grayish residue on the impeller surface, typically resulting from incomplete cleaning or contamination during processing. This issue can compromise surface quality and affect coating adhesion.

Solution: Implement a rigorous pre-treatment cleaning protocol. Begin with ultrasonic cleaning in a neutral detergent solution at 50-60°C for 10-15 minutes to remove organic contaminants and machining residues. Follow with a rinse in deionized water to eliminate detergent traces. For persistent contamination, use an alkaline cleaning solution (pH 10-12) at 60-70°C for 5-10 minutes, followed by another deionized water rinse. Ensure all cleaning equipment is free of contaminants by regularly maintaining and calibrating ultrasonic baths. After cleaning, handle impellers with clean gloves in a controlled environment to prevent re-contamination.

Uneven Surface Finish (Striped Patterns)

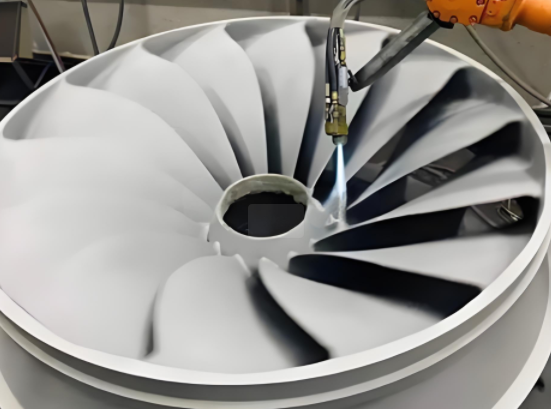

Striped patterns or uneven surface finishes can occur during mechanical polishing or grinding, often due to inconsistent tool pressure, improper abrasive selection, or inadequate process control. These defects affect the impeller’s aerodynamic performance and aesthetic quality.

Solution: Standardize the mechanical polishing process with precise parameters. Use a sequence of progressively finer abrasives, starting with 120-grit silicon carbide for initial grinding, followed by 240-grit and 400-grit abrasives for finishing. Maintain a consistent polishing speed of 1000-1500 RPM and apply a uniform pressure of 0.1-0.2 MPa. Employ automated polishing equipment to minimize human-induced variations. For complex impeller geometries, use flexible polishing tools or robotic arms to ensure uniform contact with curved surfaces. Post-polishing, inspect the surface using a roughness tester to achieve a surface roughness (Ra) of 0.4-0.8 µm, suitable for most impeller applications.

Technical Parameters for Surface Treatment Processes

The following table summarizes the key parameters for addressing common surface treatment issues, ensuring repeatability and quality control.

| Issue | Процесс | Key Parameters | Метод проверки |

|---|---|---|---|

| Over-Corrosion | Acid Pickling | HF: 2-4%, HNO₃: 20-40%, Time: 1-4 min, Temp: <40°C | Visual inspection, surface profilometer |

| Residual Oxide Scale | Abrasive Blasting + Pickling | Blasting: 0.2-0.4 MPa, Pickling: 5-7% HF (initial), 2-4% HF (final) | Magnifying lens, surface profilometer |

| Surface Contamination | Ultrasonic + Alkaline Cleaning | Ultrasonic: 50-60°C, 10-15 min; Alkaline: pH 10-12, 60-70°C, 5-10 min | Visual inspection, contact angle measurement |

| Uneven Surface Finish | Mechanical Polishing | Abrasives: 120-400 grit, Speed: 1000-1500 RPM, Pressure: 0.1-0.2 MPa | Roughness tester (Ra 0.4-0.8 µm) |

Process Optimization for Complex Impeller Geometries

Titanium alloy impellers often feature complex geometries, such as narrow channels and twisted blades, which complicate surface treatment. To address these challenges, adopt advanced machining and treatment techniques. Use high-speed five-axis CNC machines with Hypermill software to generate precise tool paths, ensuring uniform surface treatment across intricate surfaces. Customized tools, such as small-diameter end mills (Ø 2-6 mm) with TiAlN coatings, reduce tool wear and improve surface finish. Maintain a cutting speed of 50-80 m/min and a feed rate of 0.02-0.05 mm/tooth to minimize thermal deformation. Regularly calibrate equipment to maintain accuracy, and use in-process monitoring systems to detect deviations in real time.

Quality Control and Inspection Protocols

Robust quality control is critical to ensuring the effectiveness of surface treatment processes. Implement a multi-stage inspection protocol to verify surface quality at each step. Use non-destructive testing methods, such as dye penetrant inspection, to detect micro-cracks or pitting. Measure surface roughness with a profilometer to ensure compliance with the target Ra value. For critical applications, conduct X-ray fluorescence (XRF) analysis to confirm the absence of residual contaminants. Maintain detailed records of process parameters and inspection results to facilitate traceability and continuous improvement.

Environmental and Safety Considerations

Surface treatment of titanium alloy impellers involves hazardous chemicals and processes, necessitating strict safety and environmental protocols. Use fume extraction systems during acid pickling to minimize exposure to toxic vapors. Store and dispose of chemical waste in accordance with local regulations, using designated containers for acid solutions. Train operators on proper handling of chemicals and machinery, and provide personal protective equipment (PPE) such as acid-resistant gloves and face shields. Regularly audit treatment facilities to ensure compliance with occupational health and safety standards.

Case Study: Practical Application

A manufacturer of aerospace impellers faced recurring issues with over-corrosion and uneven surface finish. By implementing the solutions outlined above, they achieved significant improvements. The acid pickling process was adjusted to a 3% HF and 30% HNO₃ solution, with a pickling time of 2 minutes at 35°C, reducing pitting incidents by 90%. Mechanical polishing was standardized using 240-grit and 400-grit abrasives at 1200 RPM, achieving a consistent Ra of 0.6 µm. The adoption of five-axis CNC machining with customized tools further enhanced surface uniformity, resulting in a 15% increase in production efficiency and improved impeller performance in engine testing.

Заключение

Solving common surface treatment issues for titanium alloy impellers requires a systematic approach combining precise process control, advanced equipment, and rigorous quality assurance. By optimizing acid pickling, removing oxide scale, eliminating contamination, and standardizing polishing, manufacturers can achieve high-quality surfaces that enhance impeller performance and durability. The technical parameters and methodologies provided in this guide offer a reliable framework for professionals seeking to improve surface treatment outcomes in demanding applications.