Impeller dynamic balancing is a vital process in the maintenance and operation of rotating machinery, such as centrifugal pumps and blowers. It involves adjusting the mass distribution of an impeller to minimize vibrations caused by uneven centrifugal forces during rotation. An unbalanced impeller can lead to excessive vibrations, reducing efficiency, accelerating wear on bearings and seals, and posing safety risks. This article provides a detailed examination of the factors influencing impeller balancing, the methods employed, and practical solutions to ensure optimal performance.

Understanding Impeller Dynamic Balancing

Dynamic balancing corrects imbalances in multiple planes of a rotating component, distinguishing it from static balancing, which addresses only a single plane. For impellers—key components in pumps that impart energy to fluids—this process is critical due to their high rotational speeds and complex geometries. The goal is to achieve a balance grade, such as G6.3 or G2.5 as per ISO 21940-11, which specifies acceptable residual unbalance levels (e.g., 6.3 mm/s for general-purpose pumps or 2.5 mm/s for precision applications). Unbalance is typically measured in gram-millimeters (g-mm), and corrections aim to bring it within tolerance—for instance, a 500-gram impeller rotating at 3,600 RPM might require residual unbalance below 20 g-mm for smooth operation.

In industrial settings, such as water treatment or oil refining, balanced impellers enhance pump performance, reduce energy consumption, and extend equipment lifespan. Failure to balance an impeller can increase vibration amplitudes beyond acceptable limits (e.g., >4 mm/s), leading to mechanical fatigue and downtime.

Factors Affecting Impeller Dynamic Balancing

Several technical factors determine the complexity and precision required for impeller balancing. These factors must be analyzed to select the appropriate balancing approach and equipment.

Impeller Design and Geometry

The physical structure of an impeller significantly affects its balancing needs. Closed impellers, with shrouds on both sides, are more prone to dynamic unbalance due to their axial length, often exceeding 10% of their diameter (e.g., a 300-mm diameter impeller with a 40-mm width). Open or semi-open impellers, with fewer blades, may experience less dynamic unbalance but require precise static balancing. Blade count (e.g., 6 vs. 12) and asymmetry in design can also introduce uneven mass distribution, necessitating two-plane corrections.

Скорость вращения

Rotational speed amplifies the effects of imbalance. At 1,800 RPM, a 1-gram imbalance at a 100-mm radius generates approximately 35 N of centrifugal force, while at 3,600 RPM, this force doubles to 70 N. High-speed impellers (above 1,500 RPM) typically require dynamic balancing to tolerances as low as 10 g-mm, whereas low-speed impellers (below 1,000 RPM) may suffice with static balancing to 50 g-mm. Vibration frequency, proportional to RPM, must remain below critical thresholds (e.g., <7.1 mm/s per ISO 10816-3) to avoid resonance.

Material and Manufacturing Tolerances

Impeller materials, such as cast iron, stainless steel, or bronze, vary in density and uniformity. For example, cast iron (density ~7.2 g/cm³) may have porosity, causing a 0.5–1% mass variation across the impeller. Manufacturing tolerances, such as ±0.1 mm in machining, can also introduce imbalances. A 1-mm shift in mass center on a 200-mm diameter impeller equates to a 100 g-mm unbalance, requiring correction. High-precision fabrication reduces initial balancing efforts.

Wear and Environmental Factors

Operational wear from erosion, corrosion, or cavitation alters an impeller’s mass over time. For instance, a 2-mm material loss on a blade edge shifts the center of mass by 0.5–1 mm, increasing unbalance by 20–50 g-mm depending on impeller size. Environmental factors, like fluid abrasiveness or temperature (e.g., 80°C vs. 20°C), accelerate degradation, necessitating periodic rebalancing every 6–12 months in harsh conditions.

Application-Specific Standards

Balancing requirements vary by industry. API 610 for centrifugal pumps mandates a G6.3 balance grade for general use, while aerospace applications may demand G1.0 (1 mm/s vibration limit). A pump handling hazardous fluids requires tighter tolerances (e.g., residual unbalance <15 g-mm) to ensure safety, compared to a water pump tolerating up to 40 g-mm.

Methods and Equipment for Impeller Balancing

Balancing methods and tools are selected based on impeller characteristics and operational demands. Below are the primary approaches and equipment used.

Static Balancing

Static balancing corrects unbalance in a single plane, suitable for impellers with a length-to-diameter ratio below 0.1 (e.g., a 200-mm diameter, 15-mm wide impeller). It involves placing the impeller on a leveling stand or roller to identify heavy spots, then adding or removing weight (e.g., 2–5 grams) until it remains level. This method achieves tolerances of 30–50 g-mm and is cost-effective for speeds below 1,000 RPM.

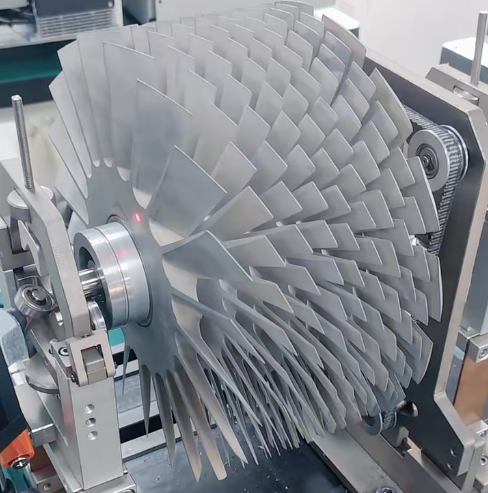

Dynamic Balancing

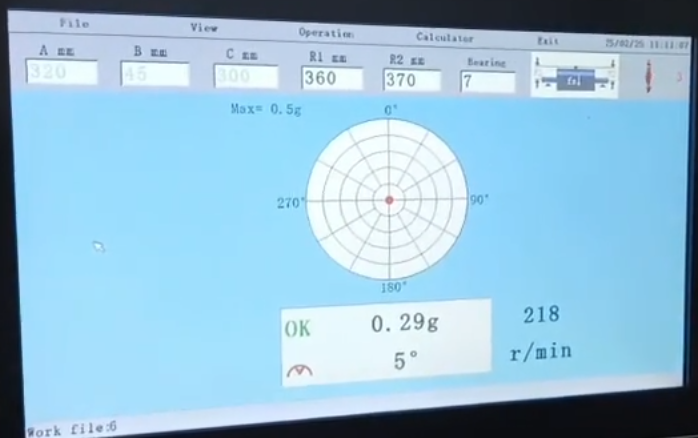

Dynamic balancing addresses multi-plane unbalance, essential for impellers operating above 1,500 RPM or with axial lengths exceeding 20% of their diameter. Using a balancing machine, it measures vibration in two planes (e.g., front and back) and corrects unbalance to within 5–20 g-mm. For a 300-mm impeller at 3,000 RPM, corrections might involve drilling 0.5–1 gram of material at specific angles (e.g., 45° and 225°). This method aligns with ISO 21940-11 standards.

Balancing Equipment

Horizontal balancing machines, with capacities up to 1,000 kg, are used for dynamic balancing, offering precision to 0.1 g-mm. Vertical machines suit smaller impellers (e.g., <50 kg) for static balancing. Vibration analyzers, measuring amplitudes as low as 0.01 mm/s, complement these machines. Modern systems integrate software to calculate correction masses and locations, reducing balancing time by 20–30%.

Solutions for Effective Impeller Dynamic Balancing

Implementing robust balancing solutions ensures long-term machinery reliability and efficiency. Below are actionable strategies.

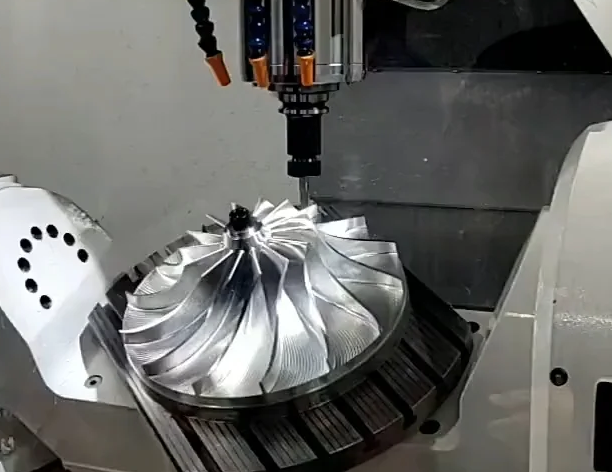

Precision Manufacturing

Manufacturing impellers with tolerances of ±0.05 mm and using CNC machining minimizes initial unbalance to 10–20 g-mm. Quality control, such as ultrasonic testing for material defects, further reduces balancing needs.

Regular Maintenance

Scheduled balancing checks every 6–12 months, or after 5,000 operating hours, detect wear-induced unbalance (e.g., >30 g-mm). Vibration monitoring during operation flags issues when amplitudes exceed 4 mm/s, prompting immediate correction.

Advanced Balancing Techniques

Using laser-guided weight adjustments or automated balancing machines achieves precision to 2–5 g-mm. Field balancing, adjusting impellers in situ, corrects minor unbalance (e.g., 10–15 g-mm) without disassembly, saving downtime.

Comparison of Balancing Methods

The table below compares static and dynamic balancing methods, detailing their applications and trade-offs.

| Method | Speed Range (RPM) | Tolerance (g-mm) | Преимущества | Ограничения |

|---|---|---|---|---|

| Static Balancing | <1,000 | 30–50 | Simple, low-cost, quick | Limited to low speeds, single-plane correction |

| Dynamic Balancing | >1,500 | 5–20 | High precision, multi-plane correction | Higher cost, requires expertise |

Factors and Their Balancing Impact

This table summarizes key factors and their influence on the balancing process.

| Фактор | Balancing Impact |

|---|---|

| Design/Geometry | Complex shapes require dynamic balancing |

| Скорость | >1,500 RPM needs tighter tolerances (e.g., <20 g-mm) |

| Материал | Porosity increases initial unbalance by 10–30 g-mm |

| Носите | Shifts mass, requiring rebalancing every 6–12 months |

Заключение

Impeller dynamic balancing is critical for optimizing pump performance, reducing vibrations, and extending machinery life. By addressing factors like design, speed, and wear with appropriate methods and equipment, industries can achieve balance tolerances as low as 5–20 g-mm, meeting standards like ISO 21940-11. Regular maintenance and precision techniques ensure reliability, making impeller balancing a cornerstone of industrial efficiency.