Impeller prototyping through machining is a critical process in industries such as aerospace, automotive, and energy, where precision and performance are non-negotiable. This guide provides a detailed, technical exploration of the materials, tools—including specialized impeller forming tools—and precision requirements essential for producing high-quality impellers using advanced CNC (Computer Numerical Control) machining techniques. The focus is on delivering practical insights based on experience, ensuring reliability, technical accuracy, and a systematic approach to impeller prototyping.

Materials for Impeller Prototyping

The selection of materials for impeller prototyping directly impacts performance, durability, and manufacturability. Impellers often operate under demanding conditions, including high rotational speeds, corrosive environments, and extreme temperatures, necessitating materials with specific mechanical properties. The choice of material also influences the machining process, including the selection of impeller forming tools.

Common Materials and Their Properties

Materials must balance strength, weight, corrosion resistance, and machinability. Below is a detailed overview of commonly used materials for impeller prototyping:

| Материал | Основные свойства | Приложения | Обрабатываемость |

|---|---|---|---|

| Aluminum Alloys (e.g., 6061-T651, 7075-T7351) | Lightweight, corrosion-resistant, tensile strength ~310 MPa (6061-T651) | Aerospace, automotive impellers, fuel systems | Excellent, compatible with standard and impeller forming tools |

| Stainless Steel (e.g., 17-4PH, 316) | High corrosion resistance, tensile strength ~1100 MPa (17-4PH) | Marine, chemical processing impellers | Moderate, requires robust impeller forming tools due to hardness |

| Титановые сплавы (например, Ti-6Al-4V) | High strength-to-weight ratio, tensile strength ~900 MPa | Aerospace, high-performance turbochargers | Challenging, needs specialized impeller forming tools |

| Инконель 718 | High-temperature resistance, tensile strength ~1370 MPa | Gas turbines, high-temperature impellers | Difficult, requires high-performance impeller forming tools |

| Polymers/Composites (e.g., PPS with 40% fiberglass) | Lightweight, corrosion-resistant, tensile strength ~100 MPa | Automotive water pumps, low-load applications | Good, but requires careful tool selection to avoid delamination |

Алюминиевые сплавы are widely used due to their ease of machining and lightweight properties, making them suitable for prototyping impellers in aerospace and automotive applications. Stainless steel and titanium alloys are chosen for corrosive or high-strength environments but pose machining challenges due to their hardness and low thermal conductivity. Inconel 718 is ideal for high-temperature applications, such as gas turbines, but requires specialized impeller forming tools and slower cutting speeds to manage its toughness.

Tools for Impeller Prototyping Machining

Machining impellers demands a range of tools tailored to the complex geometries and material properties involved. Impeller forming tools, in particular, are critical for achieving the intricate blade shapes and tight tolerances required. The following sections detail the primary tools used in impeller prototyping, with a focus on impeller forming tools and their applications.

Impeller Forming Tools

Impeller forming tools are specialized cutting tools designed to handle the unique challenges of machining impeller blades, which often feature complex, curved geometries and thin sections. These tools are typically used in 5-axis CNC machines to ensure precise material removal and surface finish. Key types of impeller forming tools include:

- Tapered Ball End Mills: These tools, with diameters ranging from 0.5 mm to 10 mm, are ideal for machining the curved surfaces of impeller blades. The tapered design reduces deflection and improves access to tight areas, ensuring smooth transitions between blade surfaces. For example, a 2 mm ball end mill with a 3° taper is commonly used for finishing aluminum impellers.

- Barrel Tools: Barrel tools have a larger radius of curvature, enabling faster material removal and better surface finish on large, curved impeller surfaces. They are particularly effective for roughing and semi-finishing operations in titanium and Inconel.

- Custom Form Tools: For specific impeller designs, custom tools with tailored profiles are used to match the blade geometry. These tools are often coated with materials like TiAlN (Titanium Aluminum Nitride) to enhance wear resistance when machining hard materials like Inconel 718.

Impeller forming tools must be selected based on the material and geometry. For instance, aluminum requires high-speed steel (HSS) or carbide tools with polished flutes to reduce chip adhesion, while titanium and Inconel demand carbide tools with coatings like AlCrN (Aluminum Chromium Nitride) to withstand high temperatures and wear.

Other Machining Tools

In addition to impeller forming tools, other tools are essential for various stages of impeller prototyping:

- Концевые фрезы: Flat-end mills (e.g., 4-flute carbide, 6-12 mm diameter) are used for roughing the impeller hub and outer contours.

- Drills and Reamers: Used for creating mounting holes or alignment features, with tolerances as tight as ±0.01 mm for high-precision applications.

- Мельницы для лица: Employed for initial stock removal, typically with 50-100 mm diameter cutters for large impellers.

Tool selection also depends on the CNC machine’s capabilities. 5-axis machines are preferred for impeller machining due to their ability to access complex geometries, reducing setup times and improving accuracy.

Precision Requirements in Impeller Prototyping

Precision is a cornerstone of impeller prototyping, as even minor deviations can significantly affect aerodynamic performance, balance, and durability. Achieving the required tolerances involves careful consideration of machining strategies, tool selection, and quality control measures.

Tolerance and Surface Finish Specifications

Impeller prototyping typically requires tight tolerances to ensure performance and compatibility with mating components. Common precision requirements include:

- Blade Profile Tolerance: ±0.02 mm to ±0.05 mm, depending on the application. Aerospace impellers often demand tighter tolerances (±0.02 mm) to maintain aerodynamic efficiency.

- Отделка поверхности: Ra (Roughness Average) values of 0.4 to 0.8 µm are typical for impeller blades to minimize drag and improve flow characteristics. Polishing or superfinishing may be required for high-performance applications.

- Concentricity and Runout: Concentricity tolerances of ±0.01 mm and runout of ±0.015 mm are critical for impeller hubs to ensure balanced rotation at high speeds (e.g., 20,000 RPM for turbochargers).

- Blade Thickness: Thin blades (e.g., 0.5-2 mm) require precise control to avoid deformation during machining, often necessitating adaptive machining strategies.

Achieving these tolerances requires advanced CNC machines with high spindle accuracy (e.g., ±0.002 mm) and robust fixturing systems to minimize vibration. Impeller forming tools play a key role in maintaining precision, as their geometry directly influences the accuracy of blade profiles and surface finishes.

Machining Strategies for Precision

Several machining strategies are employed to meet precision requirements:

- 5-Axis Simultaneous Machining: Allows continuous toolpath adjustments to follow complex impeller geometries, reducing errors from multiple setups. Typical feed rates range from 500 to 2000 mm/min, depending on material.

- Высокоскоростная обработка (HSM): Uses spindle speeds of 10,000-30,000 RPM and small stepovers (0.05-0.2 mm) to achieve fine surface finishes and minimize tool marks.

- Адаптивный клиринг: Optimizes toolpaths to maintain consistent cutting loads, reducing tool wear and improving precision when using impeller forming tools on hard materials like titanium.

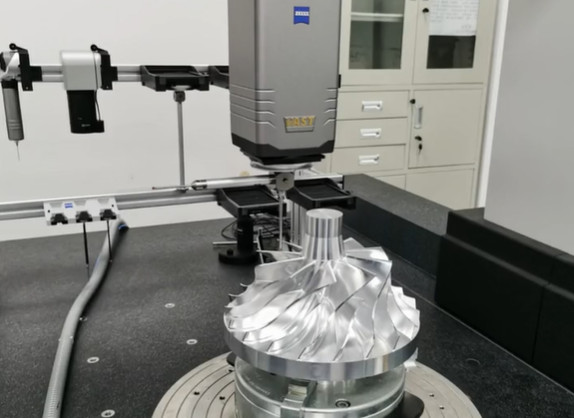

Quality control is critical, involving in-process measurements with CMM (Coordinate Measuring Machines) or laser scanners to verify tolerances. For example, a CMM with a probing accuracy of ±0.001 mm can detect deviations in blade profiles during machining.

Key Considerations in Impeller Prototyping

While impeller prototyping is a well-established process, certain considerations can impact efficiency and quality. These include:

- Material-Tool Compatibility: Mismatched tools and materials (e.g., using HSS tools on Inconel) can lead to tool wear, poor surface finish, or dimensional inaccuracies.

- Терморегулирование: Materials like titanium and Inconel generate significant heat during machining, requiring effective coolant strategies (e.g., high-pressure coolant at 70 bar) to prevent tool damage and workpiece distortion.

- Fixturing Challenges: Impellers with thin blades are prone to vibration, necessitating custom fixtures or vacuum chucks to ensure stability during machining.

Addressing these considerations requires careful planning, including the use of impeller forming tools designed for specific materials and geometries, as well as robust process optimization to minimize errors.

Заключение

Impeller prototyping machining is a complex but critical process that demands careful selection of materials, tools, and precision strategies. Aluminum, stainless steel, titanium, and Inconel are common material choices, each requiring specific impeller forming tools like tapered ball end mills or barrel tools to achieve the desired geometry and surface finish. Precision requirements, including tight tolerances and smooth surface finishes, are met through advanced CNC machining techniques and rigorous quality control. By addressing key considerations such as material-tool compatibility and thermal management, manufacturers can produce high-quality impellers that meet the stringent demands of aerospace, automotive, and energy applications. This systematic approach ensures reliability, performance, and efficiency in impeller prototyping.