Stainless steel impellers are critical components in industries such as aerospace, automotive, and marine, where high precision, durability, and corrosion resistance are essential. Achieving the required dimensional accuracy and surface quality during machining is vital for performance and longevity. Two prominent methods for machining stainless steel impellers are Electrical Discharge Machining (EDM) and Grinding. This article provides a detailed comparison of these techniques, focusing on their processes, precision capabilities, surface finish, material considerations, and practical applications. The analysis is grounded in technical data and practical experience to assist engineers and manufacturers in selecting the appropriate method.

Overview of EDM and Grinding Processes

Understanding the fundamental principles of EDM and Grinding is essential for evaluating their suitability for machining stainless steel impellers.

Электроэрозионная обработка (EDM)

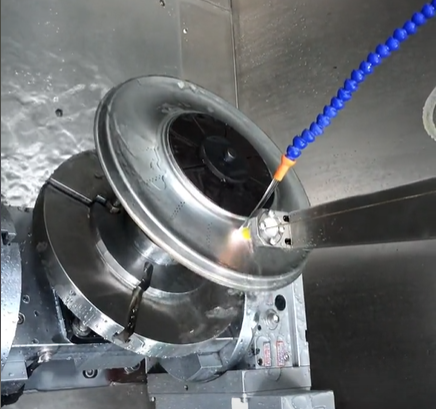

EDM is a non-traditional machining process that removes material through controlled electrical discharges (sparks) between a tool electrode and the workpiece, both submerged in a dielectric fluid. The process is ideal for conductive materials like stainless steel, regardless of hardness. EDM variants include:

- Проволочная электроэрозионная обработка: Uses a thin wire electrode to cut intricate shapes, suitable for complex impeller geometries.

- Sinker EDM: Employs a shaped electrode to create cavities or detailed features, often used for mold-like structures in impellers.

- Hole-Drilling EDM: Focuses on creating precise, deep holes, useful for impeller cooling channels or mounting features.

Key parameters in EDM include pulse duration (typically 1–100 µs), current (0.1–500 A), and spark gap (0.005–0.1 mm). The dielectric fluid, such as hydrocarbon oil or deionized water, cools the process, flushes debris, and maintains insulation. EDM is contactless, eliminating mechanical stress and tool wear from cutting forces.

Шлифование

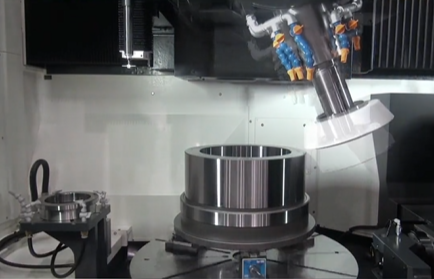

Grinding is a traditional abrasive machining process that uses a rotating wheel with bonded abrasive particles to remove material. For stainless steel impellers, surface grinding, cylindrical grinding, or creep-feed grinding are commonly employed. Grinding is highly effective for achieving tight tolerances and smooth surface finishes. Key parameters include:

- Wheel Type: Alumina, silicon carbide, or cubic boron nitride (CBN) wheels are used, with CBN preferred for stainless steel due to its hardness.

- Wheel Speed: Typically 20–40 m/s, depending on the material and wheel type.

- Скорость подачи: Ranges from 0.01–0.1 mm/pass for precision grinding.

- Coolant: Water-based or oil-based coolants reduce heat and prevent wheel clogging.

Grinding involves direct contact, generating mechanical forces and heat, which require careful management to avoid thermal damage or dimensional distortion.

Precision Capabilities

Precision is a critical factor in impeller machining, as dimensional accuracy affects performance, balance, and assembly. Both EDM and Grinding offer high precision, but their capabilities differ based on process mechanics and application.

EDM Precision

EDM achieves tolerances as tight as ±0.002 mm (±0.00008 inches) under optimal conditions. The precision depends on:

- Electrode Quality: High-precision electrodes (e.g., machined graphite or copper) ensure accurate feature replication.

- Spark Gap Control: Servo-controlled systems maintain consistent gaps, minimizing overcut (typically 0.005–0.05 mm per side).

- Machine Stability: Modern CNC EDM machines with high-resolution controls enhance repeatability.

Wire EDM excels in cutting complex 2D profiles, such as impeller vanes, with minimal deviation. Sinker EDM is ideal for 3D cavities but may require multiple electrodes for roughing and finishing to achieve high accuracy. Hole-drilling EDM can produce holes with diameters as small as 0.05 mm and aspect ratios up to 20:1.

Grinding Precision

Grinding typically achieves tolerances of ±0.005 mm (±0.0002 inches), with advanced setups reaching ±0.001 mm. Precision is influenced by:

- Wheel Dressing: Regular dressing ensures wheel geometry, critical for consistent material removal.

- Жесткость машины: High-stiffness grinders reduce vibration, improving accuracy.

- Fixturing: Secure workpiece fixturing minimizes positional errors.

Cylindrical grinding is particularly effective for impeller hubs or shafts, maintaining concentricity within 0.002 mm. Surface grinding ensures flatness and parallelism, crucial for mounting surfaces. Creep-feed grinding allows deeper cuts (up to 6 mm) with high precision, reducing machining time for large impellers.

| Параметр | EDM | Шлифование |

|---|---|---|

| Допуск (мм) | ±0.002–0.005 | ±0.001–0.005 |

| Minimum Feature Size (mm) | 0.05 (holes, wire cuts) | 0.1 (grooves, slots) |

| Aspect Ratio | Up to 20:1 (holes) | Up to 5:1 (slots) |

Surface Finish Quality

Surface finish impacts impeller efficiency, wear resistance, and fluid dynamics. Both EDM and Grinding produce distinct surface characteristics.

EDM Surface Finish

EDM surfaces typically exhibit a cratered texture due to spark erosion, with surface roughness (Ra) ranging from 0.8–4.8 µm. Finishing passes with lower current and shorter pulse durations can achieve Ra as low as 0.05 µm (mirror-like finish). Key factors include:

- Pulse Energy: Lower energy reduces crater size, improving smoothness.

- Dielectric Flushing: Effective debris removal prevents recast layers, which can increase roughness.

- Electrode Material: Graphite electrodes produce finer finishes than copper in finishing operations.

EDM’s recast layer (0.0025–0.15 mm thick) and heat-affected zone (HAZ) may require post-processing for fatigue-critical applications, such as impeller blades in turbines.

Grinding Surface Finish

Grinding produces smoother surfaces, with Ra values of 0.2–1.6 µm, and up to 0.05 µm for fine grinding. Factors affecting finish include:

- Wheel Grit Size: Finer grits (e.g., 120–320) yield smoother surfaces.

- Coolant Application: Prevents burn marks and maintains wheel sharpness.

- Скорость подачи: Slower feeds improve surface quality but increase cycle time.

Grinding avoids recast layers but may introduce residual stresses or micro-cracks if heat is not managed. Stainless steel’s tendency to clog wheels requires specialized wheels or coolants to maintain finish quality.

Material Considerations for Stainless Steel

Stainless steel, particularly austenitic grades (e.g., 304, 316), poses unique machining challenges due to its work-hardening properties and thermal conductivity.

EDM for Stainless Steel

EDM is unaffected by material hardness, making it ideal for hardened stainless steel (e.g., 17-4 PH). The process handles work-hardening without compromising tool life, as no cutting forces are involved. However, considerations include:

- Electrode Wear: Tool wear ratios (workpiece erosion/tool erosion) range from 0.5:1 to 100:1, with graphite electrodes offering better wear resistance for stainless steel.

- Material Removal Rate (MRR): Typically 0.006–0.65 cm³/h/A, slower than grinding for large volumes.

- Dielectric Fluid: Hydrocarbon oils are common, but deionized water is used for high-precision applications to reduce carbon pickup.

Grinding for Stainless Steel

Grinding requires careful parameter selection to manage stainless steel’s work-hardening and heat sensitivity. Considerations include:

- Wheel Clogging: Stainless steel particles can adhere to wheels, reducing efficiency. CBN wheels and high-pressure coolants mitigate this.

- Thermal Damage: Excessive heat can cause burns or phase changes, affecting corrosion resistance.

- MRR: Higher than EDM, ranging from 1–10 cm³/min, depending on wheel and feed rate.

Practical Applications and Selection Criteria

Choosing between EDM and Grinding depends on impeller design, production volume, and performance requirements.

Applications of EDM

EDM is preferred for:

- Сложные геометрии: Intricate vane profiles or thin-walled features where mechanical forces risk deformation.

- Hardened Materials: Machining pre-hardened stainless steel without heat treatment distortion.

- Малосерийное производство: Prototyping or custom impellers where electrode setup is cost-effective.

Example: Wire EDM is used to cut precise vane slots in a 316 stainless steel impeller with a tolerance of ±0.003 mm, achieving Ra 1.2 µm.

Applications of Grinding

Grinding is suited for:

- Крупносерийное производство: Large batches of impellers requiring consistent surface finish and tolerances.

- Large Surfaces: Hubs or mounting faces needing flatness within 0.005 mm.

- Постобработка: Refining EDM-machined surfaces to remove recast layers or improve smoothness.

Example: Cylindrical grinding finishes an impeller shaft to a tolerance of ±0.002 mm and Ra 0.4 µm using a CBN wheel at 30 m/s.

| Criteria | EDM | Шлифование |

|---|---|---|

| Геометрия | Complex, intricate | Simple, large surfaces |

| Объем производства | Low to medium | Medium to high |

| Твердость материала | Unaffected | Requires wheel selection |

Limitations and Considerations

While both methods are effective, certain limitations must be addressed.

EDM Limitations

EDM’s slower MRR makes it less efficient for large material removal. Electrode fabrication for sinker EDM adds setup time and cost. The recast layer and HAZ may require secondary processes for critical applications. Additionally, EDM is limited to conductive materials, though this is not an issue for stainless steel.

Grinding Limitations

Grinding’s mechanical forces can cause workpiece deflection in thin-walled impellers. Wheel wear and clogging increase maintenance costs, particularly for stainless steel. Thermal management is critical to prevent burns or distortion, requiring robust coolant systems.

Заключение

EDM and Grinding are both capable of achieving high precision in machining stainless steel impellers, but their suitability depends on specific requirements. EDM excels in complex geometries, hardened materials, and low-volume production, offering tolerances of ±0.002 mm and surface finishes down to Ra 0.05 µm. Grinding is ideal for high-volume production, large surfaces, and superior surface finishes (Ra 0.2–0.05 µm), with tolerances as tight as ±0.001 mm. By understanding the process mechanics, precision capabilities, and material considerations, manufacturers can select the optimal method to meet performance and cost objectives. For impellers requiring both intricate features and smooth surfaces, a hybrid approach—using EDM for roughing and Grinding for finishing—may provide the best results.