This article provides a detailed comparison of Mastercam and UG (Siemens NX) programming for CNC machining of Hastelloy impellers. Hastelloy, a nickel-based superalloy, is widely used in aerospace, chemical processing, and marine applications due to its corrosion resistance and high-temperature strength. Impellers, with their complex geometries and tight tolerances, require advanced CAD/CAM software for efficient and precise manufacturing. Mastercam and UG are two leading solutions, each with distinct strengths. This comparison focuses on technical capabilities, toolpath strategies, programming efficiency, and practical considerations, emphasizing experience-based insights and professional expertise.

Overview of Mastercam and UG for Impeller Programming

Mastercam, developed by CNC Software Inc., is a widely adopted CAD/CAM software known for its user-friendly interface and versatility across industries, including aerospace and automotive. It supports 2.5- to 5-axis machining and offers specialized modules like Blade Expert for impeller programming. UG, now Siemens NX, is a high-end CAD/CAM/CAE platform with robust capabilities for complex parts, particularly in aerospace. NX includes dedicated impeller programming modules and excels in parametric modeling and integrated manufacturing workflows.

Both software solutions are capable of programming Hastelloy impellers, but they differ in approach, complexity, and cost. Mastercam is often preferred for its accessibility and extensive post-processor library, while NX is favored for its advanced simulation and integration with PLM systems. The following sections compare their performance in key areas of impeller manufacturing.

Material Considerations for Hastelloy Impellers

Hastelloy’s high hardness (typically HRC 30-40) and low thermal conductivity make it challenging to machine. Tool wear, heat generation, and surface finish are critical concerns. Both Mastercam and NX must account for these properties through optimized toolpaths and cutting parameters.

- Tool Selection: Carbide tools with TiAlN or AlCrN coatings are recommended. Typical tool diameters range from 6 mm for finishing to 16 mm for roughing.

- Cutting Parameters: Spindle speeds of 800-1200 RPM, feed rates of 0.05-0.1 mm/tooth, and depths of cut of 0.2-0.5 mm for finishing are common.

- Coolant: High-pressure coolant (70-100 bar) is essential to manage heat and chip evacuation.

Mastercam’s Dynamic Motion technology adjusts feed rates dynamically to minimize tool wear, while NX’s adaptive milling strategies optimize chip thickness. Both approaches reduce thermal stress on Hastelloy, but NX’s parametric control allows finer adjustments based on material properties.

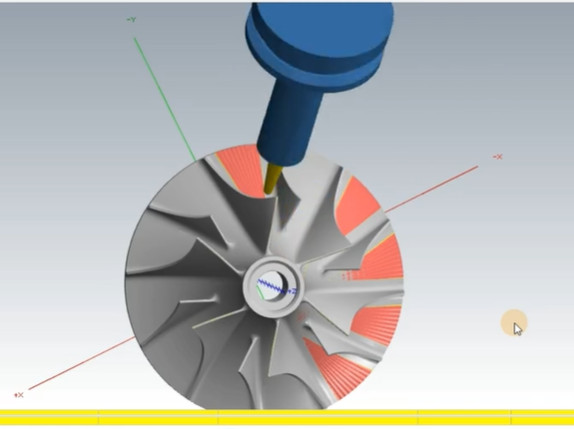

Toolpath Generation for Impeller Machining

Impeller machining typically involves 5-axis simultaneous milling due to the complex blade geometries, narrow flow channels, and tight tolerances (e.g., ±0.02 mm). Toolpath generation is a core differentiator between Mastercam and NX.

Mastercam Toolpath Strategies

Mastercam’s Blade Expert module is tailored for impellers, offering dedicated strategies for roughing, semi-finishing, and finishing. Key toolpaths include:

- OptiRough: A high-efficiency roughing strategy that removes material in layers with dynamic feed rate adjustments. Parameters: stepover 30-40% of tool diameter, axial depth 0.5-1.0 mm.

- Multiaxis Roughing: Targets blade surfaces with 5-axis motion, ensuring consistent chip loads. Stepdown: 0.3-0.6 mm.

- Blade Finishing: Uses ball-end mills (e.g., 6 mm) for smooth surfaces, with stepover of 0.1-0.2 mm and tolerance of 0.01 mm.

Mastercam’s interface allows quick setup, with automated feature recognition for hubs and blades. Its post-processor library ensures compatibility with most 5-axis machines, such as DMG Mori or Mazak.

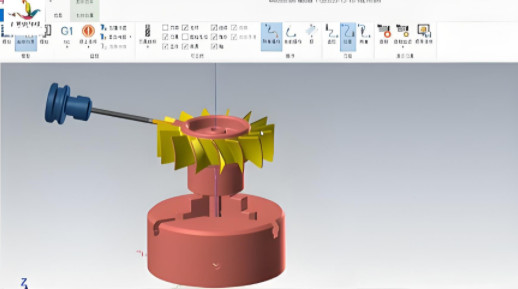

NX Toolpath Strategies

NX’s impeller programming module automates toolpath generation for hubs, blades, and shrouds. Key strategies include:

- Adaptive Roughing: Maintains constant chip thickness, reducing tool wear. Parameters: stepover 25-35%, depth of cut 0.4-0.8 mm.

- Streamline Finishing: Optimizes tool orientation for blade surfaces, minimizing scallops. Stepover: 0.08-0.15 mm, tolerance: 0.005 mm.

- Hub Finishing: Uses 5-axis swarf cutting for smooth transitions, with stepover of 0.1 mm.

NX’s parametric toolpaths allow real-time adjustments based on geometry changes, and its simulation verifies toolpaths against machine kinematics, reducing setup errors.

Comparison

Mastercam’s toolpaths are faster to generate due to its streamlined interface, making it suitable for job shops with diverse workloads. NX’s toolpaths offer superior precision and control, ideal for aerospace applications requiring stringent tolerances. For Hastelloy, NX’s adaptive strategies may extend tool life slightly more than Mastercam’s dynamic milling, but the difference is marginal with proper parameter tuning.

Programming Efficiency and User Experience

Programming efficiency impacts production timelines, especially for complex impellers. Mastercam and NX differ significantly in their workflows and learning curves.

Mastercam Programming Workflow

Mastercam’s interface is intuitive, with a shallow learning curve. A typical impeller programming workflow includes:

- Importing CAD model (e.g., STEP or IGES).

- Defining stock and fixtures using automated tools.

- Selecting toolpaths from Blade Expert, adjusting parameters (e.g., stepover, feed rate).

- Simulating toolpaths and generating G-code.

Programming a Hastelloy impeller (e.g., 200 mm diameter, 5 blades) takes 2-4 hours for an experienced user. Mastercam’s extensive tutorials and community support enhance productivity.

NX Programming Workflow

NX’s workflow is more complex due to its parametric environment. Steps include:

- Importing or modeling geometry in NX CAD.

- Defining machining regions (hub, blades, shroud) using feature-based tools.

- Generating toolpaths with impeller module, fine-tuning parameters.

- Simulating toolpaths with machine kinematics and exporting G-code.

Programming the same impeller may take 3-6 hours, reflecting NX’s steeper learning curve. However, NX’s integration with PLM systems streamlines data management in large organizations.

Comparison

Mastercam is faster for small to medium-sized shops due to its simplicity and quick setup. NX’s complexity is justified in high-volume production or when integrated with broader manufacturing systems. For Hastelloy impellers, both systems are efficient with proper training, but Mastercam’s accessibility gives it an edge for less experienced programmers.

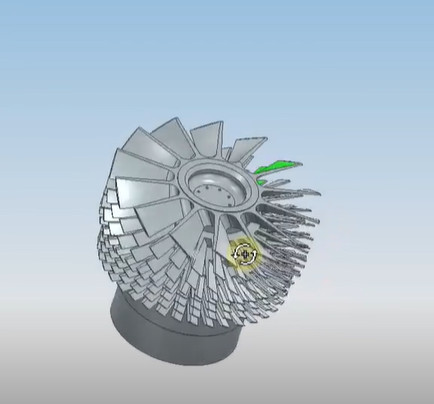

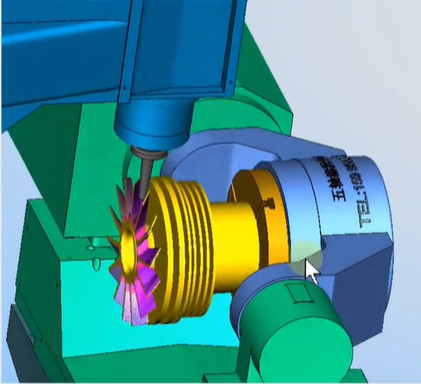

Simulation and Verification

Simulation is critical for impeller machining to prevent collisions, tool breakage, and material waste, especially with Hastelloy’s high cost.

Mastercam Simulation

Mastercam’s integrated simulation visualizes toolpaths, stock removal, and machine motion. Key features:

- Backplotting for toolpath verification.

- Material removal simulation with color-coded stock analysis.

- Collision detection for tools, fixtures, and machine components.

Simulation is user-friendly but may require third-party software like VERICUT for advanced machine kinematics verification.

NX Simulation

NX’s simulation is more robust, integrating machine kinematics and G-code verification. Features include:

- 3D simulation of toolpaths and stock removal.

- Machine-specific kinematics modeling (e.g., DMG Mori DMU 50).

- Nonlinear error detection for 5-axis machining.

NX’s native simulation reduces reliance on external tools, ensuring higher accuracy for complex setups.

Comparison

NX’s simulation is superior for aerospace-grade impellers due to its machine-specific modeling and error detection. Mastercam’s simulation is adequate for most applications but may need supplementary tools for high-precision work. For Hastelloy, NX’s robustness minimizes risks, but Mastercam’s simplicity suffices for less demanding tolerances.

Cost and Accessibility

Cost and accessibility influence software adoption, particularly for small to medium-sized enterprises.

| Aspect | Mastercam | NX (UG) |

|---|---|---|

| Initial Cost | $10,000-$50,000 (depending on modules) | $50,000-$100,000+ |

| Annual Maintenance | $2,000-$5,000 | $5,000-$10,000 |

| Training Resources | Extensive tutorials, community forums | Limited English resources, Siemens support |

| Programmer Availability | High (widely used) | Moderate (specialized) |

Mastercam’s lower cost and widespread use make it accessible for job shops. NX’s higher cost is justified for large organizations with complex workflows. For Hastelloy impeller production, Mastercam offers a cost-effective solution, while NX suits high-budget, high-precision projects.

Practical Considerations for Hastelloy Impeller Manufacturing

Key considerations include machine compatibility, programmer expertise, and production volume. Mastercam’s extensive post-processor library ensures compatibility with most CNC machines, while NX requires custom posts for non-standard setups. Programmer expertise is critical: Mastercam’s ease of use suits varied skill levels, while NX demands advanced training. For low to medium volumes, Mastercam’s quick programming is advantageous; for high volumes, NX’s automation and integration excel.

Conclusion

Mastercam and UG (NX) are both capable of programming Hastelloy impellers, but their strengths cater to different needs. Mastercam offers simplicity, cost-effectiveness, and accessibility, making it ideal for job shops and small to medium-sized enterprises. NX provides superior precision, simulation, and integration, suiting aerospace and high-volume production. The choice depends on budget, production requirements, and programmer expertise. For Hastelloy impellers, both systems deliver reliable results with proper parameter optimization and training.