Quality Die Casting Service

Die casting is a highly efficient manufacturing process used to produce complex, high-precision metal parts by forcing molten metal into reusable steel molds, known as dies, under high pressure. This technique allows for the creation of intricate shapes with tight tolerances, excellent surface finishes, and consistent quality, making it ideal for industries requiring durable and reliable components.

- High Precision and Accuracy

- Excellent Surface Finish

- Material Versatility

- Durability and Strength

Why Choose Our Die Casting Services?

High Quality Parts

ISO 9001:2015 certified, KeSu provides precision die casting with thorough quality inspections at various stages: pre-production, in-production, first article inspection, and pre-delivery. From die casting material selection to final inspection, our dedication ensures unparalleled excellence in die-cast components.

Fast Lead Time

Competitive Pricing

Die Casting Specialist

Expertise & Experience

Advanced Equipments

From Design to Prototyping to Production

- 15+ Years of Experience

- ISO 9001:2015 certified QMS

- CMM Quality Inspections

- Surface Finishing Options

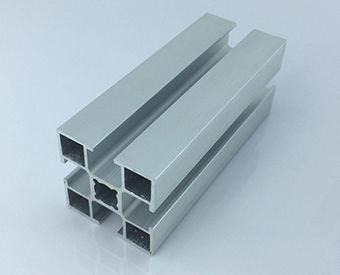

Custom Die Casting service

1

Rapid Prototyping

We offer high-quality rapid prototyping services in China, providing you with more competitive die casting prices and faster delivery times. We have developed the latest rapid prototyping technology to meet your design challenges, and will work with you to verify and improve your product die casting prototyping, conduct functional testing, and carry out engineering verification.

2

Rapid Manufacturing

KeSu is your best die casting manufacturing partner in China. We offer a range of solutions from effective rapid prototyping to production of die casting parts. Our die casting company's rich machining experience and ability to integrate resources enable us to meet the needs of any projects and ensure your parts always meet the highest quality standards.

3

Custom Die Casting

We provide one-stop rapid die casting services and cost-effective rapid custom die casting machining services. Do you need production-grade materials, complex geometric shapes, tight tolerances, or fine details? Working with the KeSu die casting factory, you can get die casting parts to the specs you require through the design prototyping and manufacturing process.

We've helped thousands of customers succeed

Thomas

Sales Manager

Addison.H

Head of Designer

Nancy. K

Engineer

He is my long term supplier with all my trust.

Can we please proceed the order for parts as quoted? Drawings and quote attached.

Die Casting Materials

| Name | Description |

|---|---|

| Aluminum Die Casting |

Lightweight and strong, aluminum is ideal for automotive and aerospace parts requiring durability and minimal weight. Alloys include ADC12, ADC6, A360, A380. Advantages: 1. Lightweight & Strong: Delivers robust components without added weight. 2. Corrosion Resistance: Naturally withstands corrosion, ensuring longevity. 3. Malleability: Allows for intricate die-cast designs. 4. Cost-Effective: Abundance makes die casting affordable. 5. Thermal Conductivity: Excels in heat dissipation, ideal for heat-sensitive components. |

| Zinc Die Casting |

Known for its toughness, zinc enables precise, high-tolerance casting for intricate designs and durable components. Alloys include Zamak 3, Zamak 5, Zamak 2, ZA8. Advantages: 1. Precision & Detail: Allows for high-precision components with intricate details. 2. High Strength: Offers exceptional durability and resistance to wear. 3. Ease of Casting: Fluidity ensures smooth, defect-free components. 4. Extended Lifespan: Resistant to environmental impacts, ensuring longer product life. 5. Cost-Effective Finishing: Achieves smooth finish, reducing post-processing costs. |

| Magnesium Die Casting |

The lightest structural metal, magnesium offers an excellent stiffness-to-weight ratio, ideal for weight-sensitive applications. Alloys include AZ91D, AM60B. Advantages: 1. Ultra-Lightweight: Produces the lightest metal components. 2. High Strength-to-Weight Ratio: Maintains impressive strength despite lightness. 3. Excellent Damping Capacity: Absorbs vibrations, ideal for noise reduction. 4. Rapid Production: Allows faster die casting cycles for quicker production. 5. Eco-Friendly: Recyclable and requires less energy in production. |

| Copper Die Casting | Copper is excellent for parts such as heat sinks and electrical connectors due to its effective heat and electricity conductivity. Alloys include ZQA19-2, ZQA19-4, ZQA19-7, ZQA19-10. |

| Name | Description |

|---|---|

| As Cast | Provides a basic, functional finish for die casting products with relatively smooth surfaces and minor tool marks, suitable for non-cosmetic applications. |

| Polishing | Enhances the surface smoothness and shine of metal casts, reducing surface roughness to achieve a high-gloss finish that is visually appealing. |

| Sand Blasting | Offers a uniform, matte finish by blasting the surface with fine particles, which also helps to remove small imperfections and prepare the surface for further treatments. |

| Anodizing | Increases corrosion resistance and wear properties of aluminum cast parts, while also adding the option for coloration, enhancing both durability and aesthetics. |

| Powder Coating | Creates a thick, uniform coating that is tougher than conventional paint. Ideal for adding vibrant colors and additional protection against corrosion and chipping. |

| Brushed Finish | Produces a distinctive look with a pattern of fine lines on the metal surface, which can help in hiding fingerprints and minor scratches, adding both aesthetics and practicality. |

Die Casting FAQs

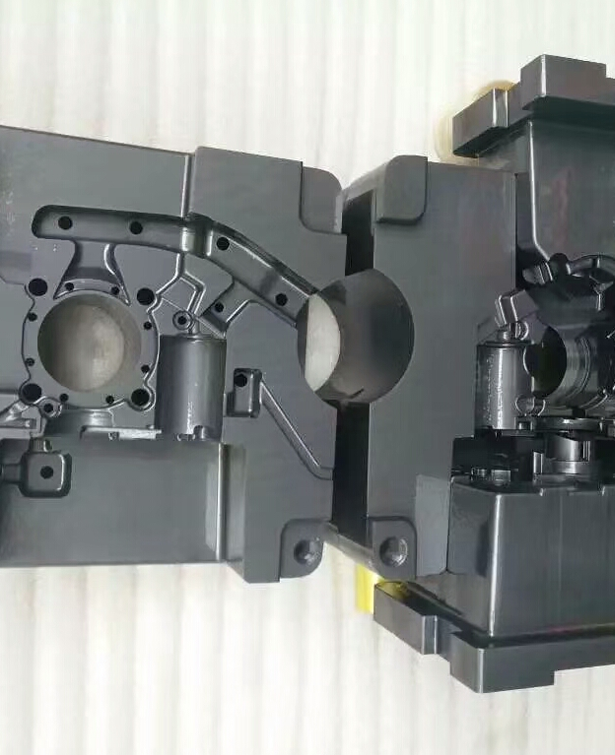

What is the die casting process?

Die casting is a precision manufacturing process where molten metal is forced under high pressure (1,500–25,000 psi) into a steel mold, or die, to create complex parts. The process includes:

- Mold Preparation: The die is lubricated and preheated for easy part removal and temperature control.

- Metal Injection: Molten metal is injected into the die at high speed and pressure.

- Cooling: The metal cools and solidifies rapidly within the mold.

- Ejection: The die opens, and the solidified part is ejected.

- Trimming: Excess material (flash, gates) is removed.

What are the advantages of die casting?

- High Precision: Achieves tight tolerances (±0.1–0.5 mm) and complex shapes consistently.

- Fast Production: Rapid cycle times enable high-volume manufacturing.

- Strong, Lightweight Parts: Dense metal structure ensures durability with minimal weight.

- Low Waste: Efficient material use reduces scrap and secondary machining needs.

What are the disadvantages of die casting?

- High Initial Costs: Expensive dies and machines make it less viable for small runs.

- Material Limitations: Best suited for low-melting-point metals like aluminum and zinc.

- Porosity Risk: Rapid cooling may trap air, causing internal voids.

- Size Constraints: More effective for smaller parts; large components may lose accuracy.

What are key design considerations for die casting?

What is the lead time for die cast tooling?

Lead time for die cast tooling typically ranges from 2 to 12 weeks, depending on part complexity, material, and precision requirements. This includes design, mold machining, testing, and adjustments to ensure quality.

What are the tolerances for die casting?

Die casting tolerances vary by part size and material, typically ranging from ±0.1 mm for dimensions under 25 mm to ±0.5 mm for up to 250 mm. Tighter tolerances (±0.02 mm) are possible with post-machining. Materials like aluminum and zinc affect shrinkage and accuracy.

Can die cast parts be post-machined?

Yes, die cast parts can be post-machined to achieve tighter tolerances, smoother finishes, or complex features. Common processes include drilling, milling, and CNC machining, which correct defects like porosity and enhance precision for high-performance applications.

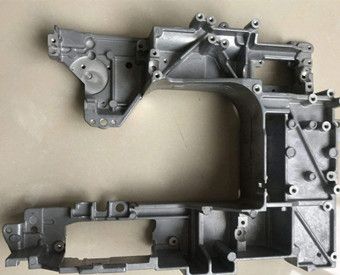

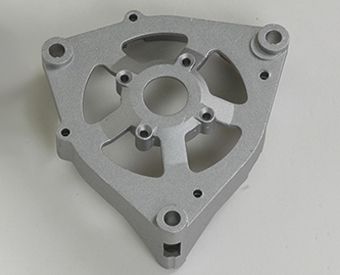

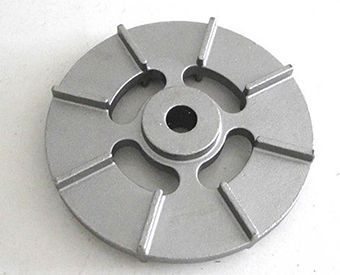

Die Casting Parts

Quote Now to Start Your Die Casting Project

Complete Die Casting services from prototype to production ensure high quality, fast delivery and competitive prices.