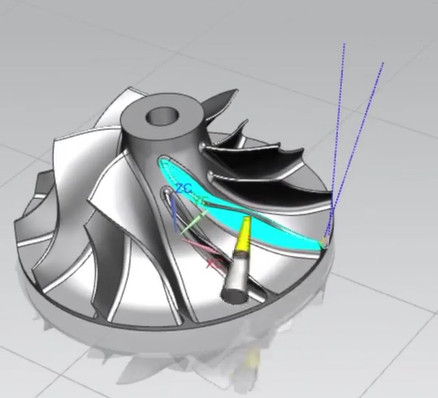

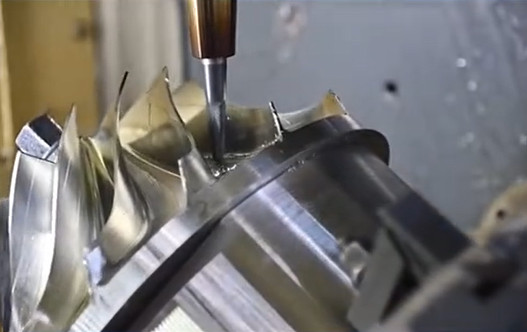

Aluminum alloy impellers are critical components in fluid machinery, such as pumps, compressors, and fans, due to their lightweight properties, machinability, and corrosion resistance. However, machining these components presents specific technical requirements, particularly in tool selection and coating application, to achieve high efficiency and surface quality. This article provides a detailed, experience-based analysis of coating tool selection for aluminum alloy impellers, focusing on technical parameters, performance metrics, and practical considerations to ensure optimal machining outcomes.

Material Properties of Aluminum Alloy Impellers

Aluminum alloys, such as Al6061, Al6063, and Al7075, are commonly used for impellers due to their favorable properties. These alloys offer a balance of low density (approximately 2.7 g/cm³), good mechanical strength (yield strength ranging from 145 MPa for Al6063 to 503 MPa for Al7075-T6), and moderate corrosion resistance. However, their softness and low melting point (around 580–660°C) make them prone to adhesion to cutting tools, leading to built-up edge (BUE) formation and poor surface finish if improper tools or parameters are used.

Surface treatments, such as anodizing, can enhance corrosion resistance but may complicate machining due to increased surface hardness. For impellers, Al6061 is often preferred for its machinability and cost-effectiveness, while Al7075 is chosen for high-performance applications requiring greater strength, such as aerospace impellers. Understanding these material properties is essential for selecting appropriate coating tools to minimize wear and maximize efficiency.

Requirements for Coating Tools in Impeller Machining

Machining aluminum alloy impellers involves high-speed cutting, typically at spindle speeds of 1000–10,000 RPM, and feed rates of 0.05–0.3 mm/rev, depending on the alloy and operation (roughing or finishing). The primary requirements for coating tools include:

- Low Affinity to Aluminum: Coatings must prevent adhesion to avoid BUE, which degrades surface quality and increases cutting forces.

- High Wear Resistance: Tools must withstand abrasive wear from silicon or other alloying elements in aluminum.

- Thermal Stability: Coatings should manage heat generation, as excessive heat can soften the workpiece or tool.

- Chip Evacuation: Efficient chip removal is critical to prevent clogging, especially in complex impeller geometries.

- Surface Finish: Tools must achieve low surface roughness (Ra 0.8–1.6 µm for general applications, Ra 0.2–0.8 µm for precision impellers).

These requirements are influenced by the impeller’s complex geometry, including curved vanes and thin-walled structures, which demand precise tool paths and minimal vibration during machining.

Types of Coating Tools for Aluminum Alloy Impellers

Several coating types are suitable for machining aluminum alloys, each offering distinct advantages based on their composition and properties. The following table summarizes the key characteristics of common coatings used for impeller machining:

| Coating Type | Composition | Hardness (HV) | Max Working Temp (°F) | Coefficient of Friction | Applications |

|---|---|---|---|---|---|

| TiB2 (Titanium Diboride) | Ti-B | 2804 | 900 | 0.35 | Non-abrasive aluminum alloys (e.g., Al6061, Al6063) |

| ZrN (Zirconium Nitride) | Zr-N | 2243 | 1110 | 0.40 | Abrasive aluminum alloys (e.g., Al7075 with silicon) |

| DLC (Diamond-Like Carbon) | C-based | 2000–4000 | 750 | 0.10–0.20 | High-speed finishing of precision impellers |

| PCD (Polycrystalline Diamond) | Diamond | 8000–12000 | 1470 | 0.05–0.10 | High-performance impellers in aerospace |

TiB2 Coating

TiB2 is widely used for machining non-abrasive aluminum alloys due to its low affinity to aluminum, which prevents BUE formation. Its hardness (HV 2804) and low coefficient of friction (0.35) ensure extended tool life and efficient chip evacuation. TiB2 is ideal for roughing and semi-finishing operations on Al6061 impellers, where spindle speeds of 5000–8000 RPM and feed rates of 0.1–0.2 mm/rev are common. However, it is less effective for abrasive alloys containing high silicon content, as the coating may wear prematurely.

ZrN Coating

ZrN is suitable for abrasive aluminum alloys, such as Al7075, due to its moderate hardness (HV 2243) and higher working temperature (1110°F). It provides good abrasion resistance and lubricity, making it effective for machining impellers with complex geometries. ZrN-coated tools are often used at spindle speeds of 3000–6000 RPM and feed rates of 0.05–0.15 mm/rev to achieve surface roughness values of Ra 0.8–1.2 µm. Its cost-effectiveness makes it a practical choice for general-purpose impeller machining.

DLC Coating

DLC coatings offer a low coefficient of friction (0.10–0.20) and high hardness (HV 2000–4000), making them ideal for high-speed finishing operations. They excel in achieving ultra-smooth surfaces (Ra 0.2–0.4 µm) required for precision impellers in applications like marine propulsion systems. DLC-coated tools are typically used at spindle speeds of 8000–10,000 RPM and low feed rates (0.05–0.1 mm/rev). Their main limitation is lower thermal stability (750°F), which restricts their use in high-temperature roughing operations.

PCD Coating

PCD coatings provide exceptional hardness (HV 8000–12000) and the lowest coefficient of friction (0.05–0.10), making them the premium choice for high-performance impellers. They are used in aerospace applications, where Al7075 impellers require surface roughness values below Ra 0.4 µm. PCD tools operate effectively at spindle speeds of 6000–10,000 RPM and feed rates of 0.05–0.15 mm/rev. Their high cost is a significant consideration, but their durability justifies the investment for large-scale production.

Tool Geometry and Machining Parameters

Tool geometry plays a critical role in machining efficiency. For aluminum alloy impellers, the following parameters are recommended:

- Rake Angle: Positive rake angles (10–20°) reduce cutting forces and improve chip evacuation, minimizing heat generation.

- Clearance Angle: Positive clearance angles (5–15°) prevent tool flank wear and ensure smooth cutting.

- Helix Angle: High helix angles (30–40°) enhance chip removal, particularly in deep vane machining.

- Flute Count: 2-flute end mills are preferred for roughing due to larger chip pockets, while 3-flute tools are used for finishing to balance chip evacuation and surface quality.

Machining parameters depend on the operation type. For roughing, higher feed rates (0.15–0.3 mm/rev) and moderate spindle speeds (3000–6000 RPM) maximize material removal rates (MRR). For finishing, lower feed rates (0.05–0.1 mm/rev) and higher spindle speeds (6000–10,000 RPM) ensure precision and surface quality. Coolants, such as water-based emulsions, are often used to reduce heat and improve tool life, particularly for DLC and ZrN coatings.

Efficiency Analysis of Coating Tools

Efficiency in impeller machining is measured by MRR, tool life, surface quality, and energy consumption. The following table compares the performance of different coatings based on experimental data:

| Coating | MRR (cm³/min) | Tool Life (min) | Surface Roughness (Ra, µm) | Energy Consumption (kW) |

|---|---|---|---|---|

| TiB2 | 120–150 | 60–80 | 0.8–1.6 | 1.2–1.5 |

| ZrN | 100–130 | 50–70 | 0.8–1.2 | 1.3–1.6 |

| DLC | 80–110 | 70–90 | 0.2–0.4 | 1.1–1.4 |

| PCD | 90–120 | 100–120 | 0.2–0.4 | 1.0–1.3 |

TiB2 and ZrN coatings offer higher MRR, making them suitable for roughing operations where productivity is prioritized. DLC and PCD coatings excel in finishing, providing superior surface quality and longer tool life, though at lower MRR. Energy consumption is slightly lower for DLC and PCD due to their low friction, which reduces cutting forces. For Al6061 impellers, TiB2 is often the most cost-effective choice for general machining, while PCD is preferred for high-precision aerospace applications.

Practical Considerations in Tool Selection

Selecting the optimal coating tool involves balancing performance, cost, and application requirements. Key considerations include:

- Alloy Composition: Non-abrasive alloys favor TiB2 or DLC, while abrasive alloys require ZrN or PCD.

- Production Volume: High-volume production justifies the cost of PCD, while low-volume runs may use TiB2 or ZrN.

- Machine Rigidity: Less rigid machines benefit from low-friction coatings like DLC to reduce vibration.

- Operation Type: Roughing prioritizes MRR (TiB2, ZrN), while finishing emphasizes surface quality (DLC, PCD).

For example, in a marine cooling pump project using Al6061 impellers, TiB2-coated tools achieved a surface roughness of Ra 1.2 µm at a spindle speed of 6000 RPM and feed rate of 0.15 mm/rev, with a tool life of 70 minutes. In contrast, an aerospace Al7075 impeller required PCD tools to achieve Ra 0.3 µm at 8000 RPM and 0.05 mm/rev, with a tool life of 110 minutes.

Conclusion

Coating tool selection for aluminum alloy impellers requires a systematic approach, considering material properties, tool geometry, coating characteristics, and machining parameters. TiB2 and ZrN coatings are cost-effective for roughing and general machining, while DLC and PCD excel in precision finishing. By aligning tool selection with specific alloy types, production goals, and operational conditions, manufacturers can achieve high efficiency, extended tool life, and superior surface quality. This analysis provides a practical framework for optimizing impeller machining processes, ensuring reliable performance in demanding applications.