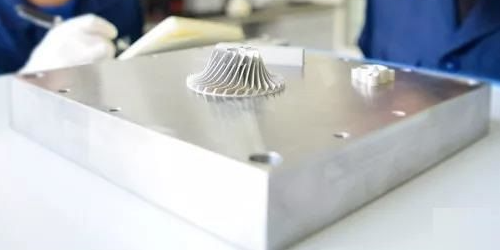

Additive manufacturing, widely recognized as 3D printing, is a transformative technology that builds objects layer by layer from digital designs. Its applications span multiple industries, including aerospace, where it enables the production of high-performance components like aviation engine parts. When paired with titanium alloys, 3D printing offers a powerful solution for modern manufacturing challenges.

Key Benefits of 3D Printing in Aerospace

The adoption of 3D printing for aviation engine parts delivers several advantages:

- Efficient Prototyping: Manufacturers can produce sample components rapidly, testing properties like strength, hardness, and density to refine designs early in the process.

- Reduced Material Waste: Unlike traditional machining, which can waste up to 95% of raw materials, 3D printing minimizes loss to approximately 5%, optimizing resource use.

- Complex Design Capability: This technology excels at creating intricate shapes critical for aviation, enhancing component functionality without added production complexity.

Why Titanium Alloys Matter

Titan-Legierungen are a cornerstone of aerospace engineering due to their unique properties:

- Lightweight Strength: With an exceptional strength-to-weight ratio, titanium reduces aircraft weight, lowering fuel costs and boosting payload capacity.

- Durability: Its resistance to corrosion and high temperatures ensures reliability in demanding flight conditions.

Known as the "space metal," titanium is a preferred material for critical engine components.

A Leader in Advanced Manufacturing

A prominent player in this field has made significant contributions to 3D printing and titanium alloy applications:

- Industry Collaboration: A strategic partnership with Siemens (China) has advanced additive manufacturing techniques, fostering innovation in production processes.

- Specialized Research: The creation of dedicated institutes, such as one focused on vanadium and titanium materials, supports the development of cutting-edge solutions for aerospace and beyond.

- Production Expansion: Efforts to extend titanium alloy powder production target high-value sectors, including aviation, defense, automotive, and medical industries.

Future Applications

The successful production of 3D-printed titanium alloy aviation engine parts marks a milestone in advanced manufacturing. This technology’s potential extends to:

- Luft- und Raumfahrt: Engine components and structural parts.

- Medizinische: Precision implants and devices.

- Automobilindustrie: Lightweight, durable parts.

Emerging metal powders, such as specialized titanium and vanadium alloys, will further broaden these applications, driving efficiency across industries.

Schlussfolgerung

The combination of 3D printing and titanium alloys represents a leap forward in aerospace manufacturing. Through ongoing innovation and strategic focus, this technology continues to redefine production standards, delivering efficient, high-quality solutions for the future.