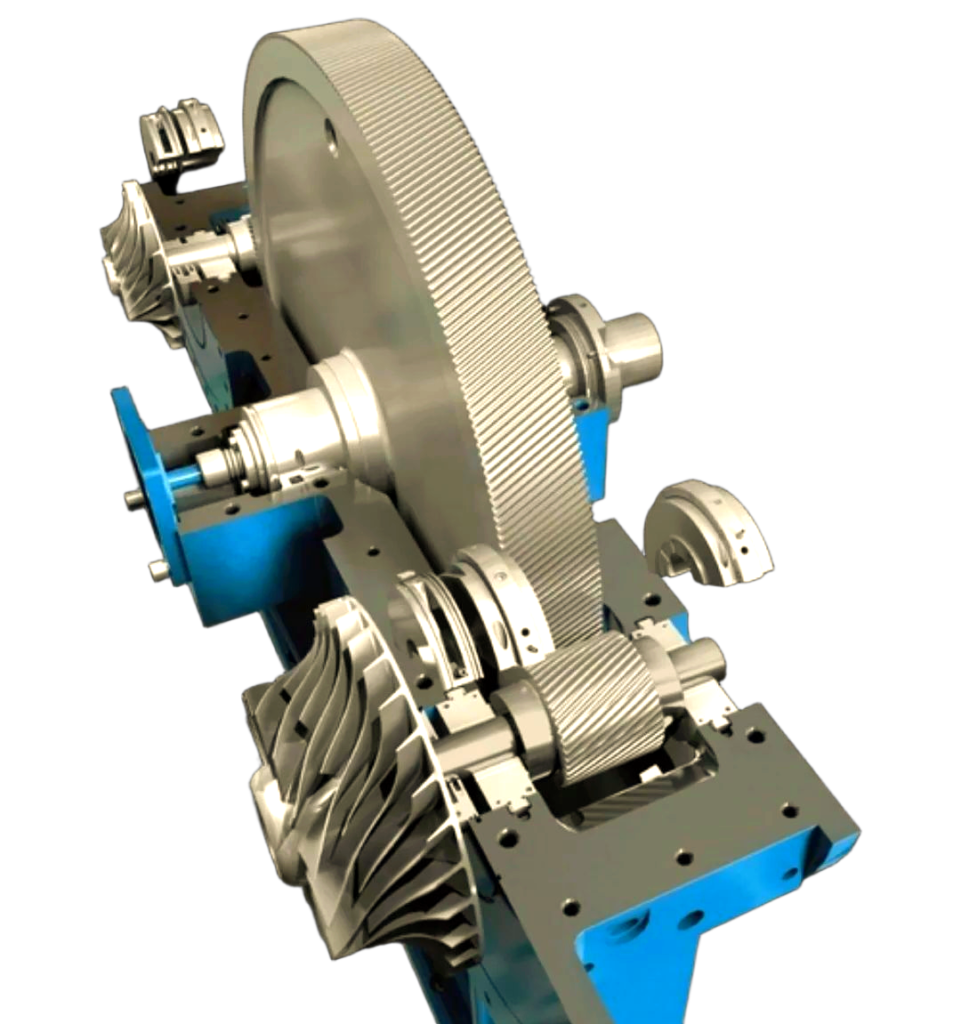

A centrifugal air compressor is a dynamic machine that compresses air by transferring energy from a rotating impeller to the air, increasing its pressure and velocity. These compressors are widely used in industries due to their ability to deliver high-pressure air efficiently. The impeller is the heart of the centrifugal compressor, as it is responsible for accelerating the air and initiating the compression process. Its design and performance directly influence the compressor’s efficiency, output, and reliability.

What Is an Impeller?

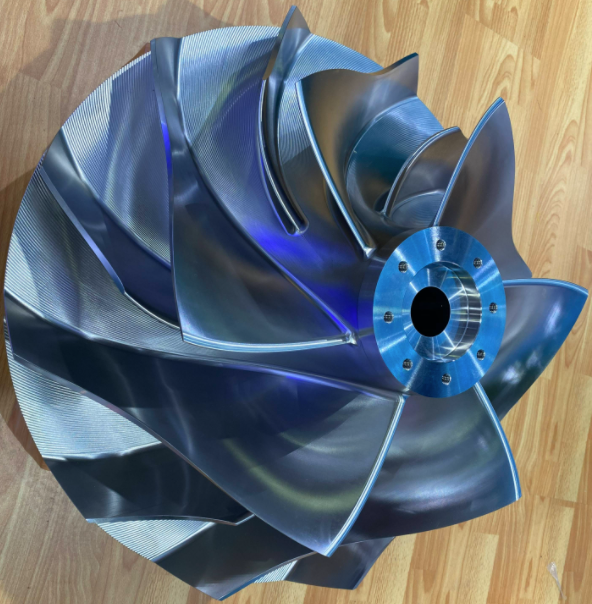

An impeller is a rotating component in a centrifugal compressor that accelerates air radially outward. It consists of a series of blades mounted on a central hub, designed to impart kinetic energy to the airflow. Unlike a turbine, which extracts energy from a fluid, or a fan, which moves large volumes of air at low pressure, an impeller is engineered to significantly increase air pressure through high-speed rotation.

Key Characteristics:

- Function: Converts mechanical energy into kinetic energy of the air.

- Materials: Typically made from aluminum alloys, titanium, or stainless steel for durability and resistance to high rotational stresses.

- Konstruktion: Fabricated through precision machining, casting, or advanced methods like 3D printing.

Role of the Impeller in Compression

The impeller plays a critical role in the compression process by performing three main functions:

- Air Intake and Acceleration: The impeller draws air into the compressor through its inlet and accelerates it radially outward due to its high rotational speed, typically ranging from 10,000 to 100,000 RPM depending on the compressor size.

- Energy Conversion: The impeller’s blades transfer mechanical energy from the motor to the air, converting it into kinetic energy. The velocity of the air can reach up to 500 m/s in high-performance compressors.

- Directing Airflow: The accelerated air is directed into the diffuser, a stationary component that slows the airflow, converting kinetic energy into static pressure. This results in compressed air with pressure ratios typically ranging from 3:1 to 10:1.

Design Features

The impeller’s design is critical to compressor performance. Key design elements include:

Blade Shape and Angle: Impellers feature radial, backward-curved, or forward-curved blades. Backward-curved blades are most common due to their balance of efficiency and stability, offering pressure ratios up to 8:1 with efficiencies of 80-90%. Radial blades are used for higher pressure applications, while forward-curved blades are less common due to lower efficiency.

Number of Blades and Diameter: The number of blades (typically 10-20) and impeller diameter (ranging from 100 mm to 1,000 mm) affect airflow and pressure. More blades increase pressure but may reduce flow rate, while larger diameters enhance flow capacity.

Rotationsgeschwindigkeit: Higher speeds increase kinetic energy but require robust materials to withstand centrifugal forces, which can exceed 100,000 N in large compressors. Speed is optimized based on the desired pressure ratio and flow rate.

| Parameter | Typical Range | Impact |

|---|---|---|

| Blade Angle | Radial, Backward-curved, Forward-curved | Affects efficiency and pressure ratio |

| Number of Blades | 10-20 | Balances pressure and flow rate |

| Durchmesser | 100-1,000 mm | Influences flow capacity |

| Rotationsgeschwindigkeit | 10,000-100,000 RPM | Determines kinetic energy output |

Performance Factors

Several factors govern impeller performance:

Effizienz: Impeller efficiency, typically 80-90%, depends on blade design and material. Losses occur due to friction, turbulence, and heat generation.

Pressure Ratio: Defined as the ratio of outlet to inlet pressure, it ranges from 3:1 to 10:1 for single-stage compressors. Multi-stage designs can achieve ratios up to 20:1.

Surge and Stall: Surge occurs when airflow reverses due to excessive pressure, potentially damaging the compressor. Stall happens when airflow separates from the blades, reducing efficiency. Both are mitigated through precise design and control systems.

Manufacturing and Materials

Impellers are constructed from materials that withstand high stress and corrosion:

- Aluminium-Legierungen: Lightweight, used in smaller compressors (stress resistance up to 400 MPa).

- Titan: High strength-to-weight ratio, ideal for aerospace applications (stress resistance up to 1,000 MPa).

- Rostfreier Stahl: Corrosion-resistant, used in harsh environments.

Manufacturing Methods: Precision machining ensures tight tolerances (e.g., ±0.01 mm), while casting is cost-effective for simpler designs. Advances in 3D printing allow complex geometries with reduced weight, improving efficiency by up to 5% in some cases.

Applications and Use Cases

Centrifugal compressors with impellers are used in:

- HVAC Systems: Provide compressed air for large-scale cooling (e.g., commercial buildings).

- Industrielle Maschinen: Power pneumatic tools and processes in manufacturing.

- Power Plants: Supply compressed air for gas turbines.

- Luft- und Raumfahrt: Used in jet engines for high-pressure air delivery.

Comparison with Axial Compressors:

| Merkmal | Centrifugal Compressor | Axial Compressor |

|---|---|---|

| Airflow Direction | Radial | Parallel to axis |

| Pressure Ratio | 3:1 to 10:1 per stage | 1.1:1 to 1.5:1 per stage |

| Anwendungen | HVAC, industrial | Jet engines, large turbines |

| Size | Compact | Larger, elongated |

Common Issues and Maintenance

Impellers face several challenges:

Erosion, Corrosion, and Fatigue: High-speed rotation and exposure to moisture or chemicals can degrade materials. Titanium and stainless steel mitigate corrosion, while regular coatings extend lifespan.

Balancing and Vibration: Imbalance causes vibrations, leading to bearing wear or blade failure. Dynamic balancing to tolerances of 0.01 g·mm reduces risks.

Maintenance: Regular inspections (e.g., every 2,000-5,000 operating hours) detect cracks, wear, or imbalance. Non-destructive testing (e.g., ultrasonic or dye penetrant) ensures integrity.

Schlussfolgerung

The impeller is the cornerstone of centrifugal air compressors, driving air acceleration, energy conversion, and pressure build-up. Its design, material, and maintenance significantly impact compressor performance and longevity. By optimizing blade geometry, material selection, and manufacturing techniques, impellers achieve high efficiency and reliability across diverse applications, from HVAC to aerospace.