Compressor impellers are critical components in turbomachinery, requiring precision manufacturing to meet stringent performance and dimensional requirements. Machining these complex parts, typically from solid forgings, involves intricate processes such as 5-axis CNC milling. Reducing lead time in impeller machining is essential to improve production efficiency, meet customer demands, and maintain competitiveness. This article outlines systematic strategies to shorten lead time, focusing on technical optimization, process planning, and practical implementation, with detailed parameters where applicable.

Optimizing Machining Strategy Selection

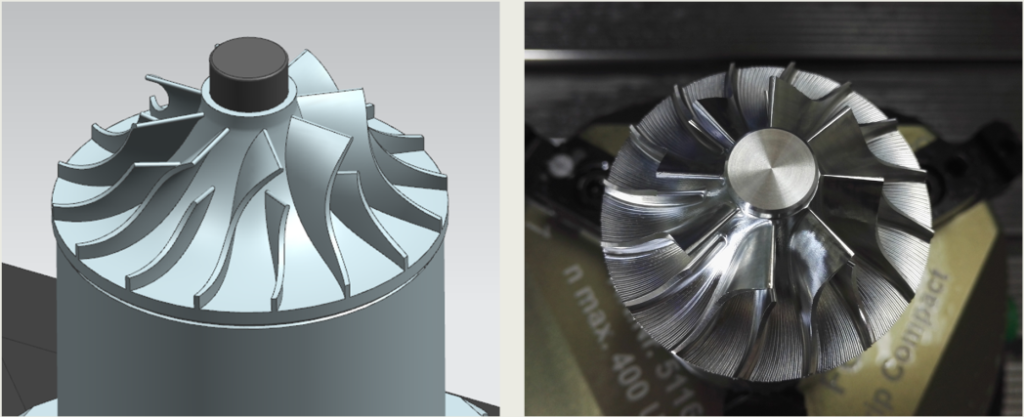

Selecting the appropriate machining strategy is foundational to reducing lead time. Compressor impellers, characterized by complex geometries like twisted blades and narrow flow passages, require careful planning of roughing, semi-finishing, and finishing phases. Each phase must balance material removal rates, tool life, and surface quality.

Roughing Phase: The roughing phase aims to remove the bulk of material quickly. Using larger diameter tools (e.g., 12-16 mm for wider sections) for the inlet and outlet areas of impeller flow passages, where geometry permits, maximizes material removal. For narrower sections, smaller tools (e.g., 6-8 mm) are used to avoid tool deflection. Cutting parameters include a spindle speed of 8,000-12,000 RPM, feed rate of 1,200-2,000 mm/min, and depth of cut of 2-4 mm per layer, depending on material (e.g., Inconel or titanium).

Semi-Finishing Phase: This phase refines the impeller’s geometry, preparing it for finishing. A step-over distance of 0.8-1.2 mm ensures smooth transitions between tool paths. Ball-end mills (e.g., 8 mm diameter) are often used, with spindle speeds of 10,000-15,000 RPM and feed rates of 800-1,500 mm/min. This phase reduces residual material while maintaining dimensional accuracy.

Finishing Phase: Finishing achieves the final surface quality and dimensional tolerances (e.g., ±0.02 mm). A step-over distance of 0.2-0.4 mm is critical to minimize cusp height and ensure surface roughness (Ra 0.8-1.6 µm). Flank milling is preferred for radial impellers due to faster machining times compared to point milling, with spindle speeds of 12,000-18,000 RPM and feed rates of 500-1,000 mm/min. Using specialized CAM software, such as MAX-PAC, optimizes tool paths to avoid collisions and reduce machining time.

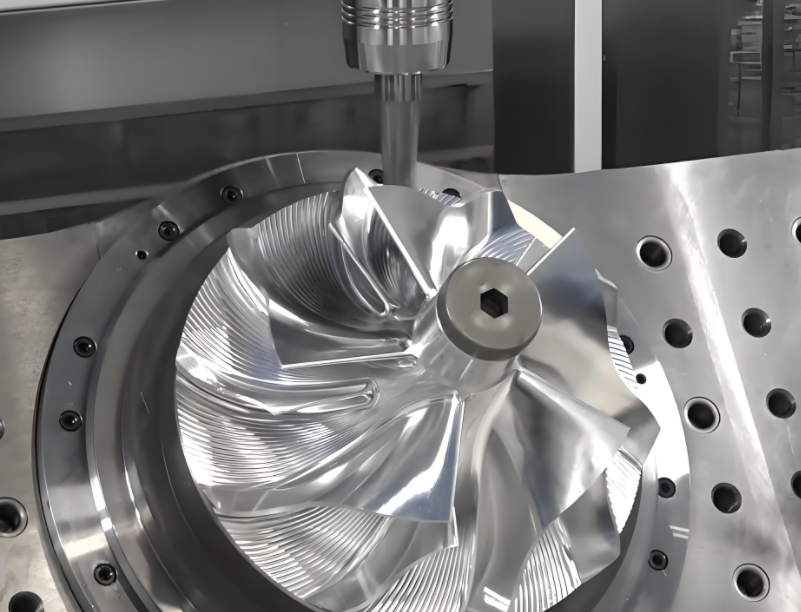

Implementing 5-Axis CNC Machining

Five-axis CNC machining is critical for impeller production due to its ability to access complex geometries. This technology reduces setup times and improves precision, directly impacting lead time.

Optimierung der Werkzeugwege: Five-axis machines allow simultaneous control of tool orientation, enabling efficient machining of twisted blades and shrouded impellers. Tool paths should be generated using CAM software to minimize non-cutting movements. For example, a continuous spiral tool path reduces tool retractions, cutting lead time by up to 15%. Parameters include a tool tilt angle of 10-30° to avoid collisions and a lead angle of 5-10° for smooth cutting.

Tool Selection: Ball-end and tapered end mills (e.g., 6-10 mm diameter) are commonly used. For high-temperature alloys like Inconel, coated carbide tools with a hardness of 60-65 HRC are recommended. Tool length-to-diameter ratios should not exceed 4:1 to minimize deflection, which can increase machining time due to rework.

Machine Dynamics: Machine stiffness and spindle dynamics are critical. A machine with a minimum spindle power of 20 kW and rigidity to handle cutting forces (e.g., 500-1,000 N) ensures stable operation. Regular calibration of rotary axes maintains accuracy, reducing lead time by avoiding errors that require rework.

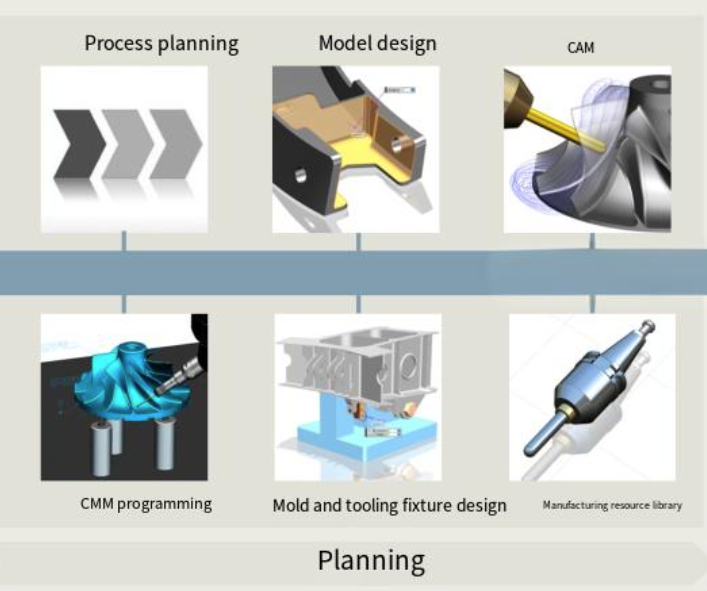

Streamlining Process Planning

Effective process planning minimizes delays across the manufacturing workflow, from order receipt to final inspection. A systematic approach ensures all stages are aligned to reduce lead time.

Workflow Analysis: Map the entire process, from material procurement to delivery, to identify bottlenecks. For example, delays in material staging or tool setup can add hours to lead time. Consolidating tasks, such as grouping components frequently used together, reduces parts-gathering time by 10-20%.

Parallel Processing: Running processes simultaneously, such as material preparation during machine setup, can save significant time. For instance, staging tools and fixtures while the previous job runs can reduce changeover time by 30-50 minutes per setup.

Preventive Maintenance: Scheduled maintenance of CNC machines prevents unexpected downtime. A maintenance schedule targeting 95% machine availability includes weekly checks of spindle bearings and monthly calibration of linear axes. This reduces unplanned downtime, which can extend lead time by days.

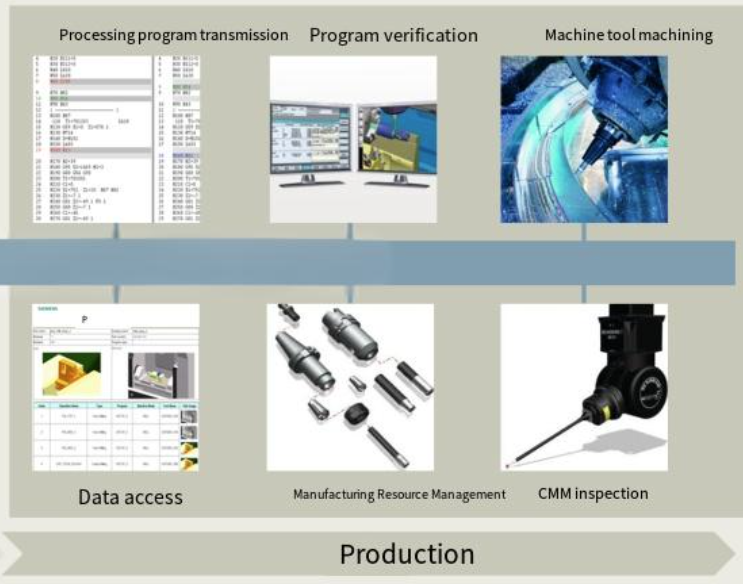

Leveraging Automation and Digital Tools

Automation and digital tools enhance efficiency by reducing manual intervention and improving process visibility.

Automation Equipment: Automated tool changers and robotic loading systems reduce setup and handling times. For example, a robotic arm can load forgings in 2-3 minutes compared to 5-10 minutes for manual loading. Conveyors for chip removal further minimize interruptions, saving 5-10 minutes per hour of machining.

Real-Time Monitoring: Sensors and IoT-enabled devices provide real-time data on machine performance and tool wear. Monitoring spindle load (e.g., maintaining 70-80% of maximum capacity) prevents tool breakage, which can delay production by hours. Software like Tulip collects data to identify delays, enabling adjustments that reduce lead time by 10-15%.

Digital Work Instructions: Digitized instructions with integrated IoT reduce operator errors. For instance, interactive work instructions on a tablet can cut task completion time by 20% compared to paper-based systems, ensuring consistent machining parameters.

Improving Supply Chain Management

Supply chain efficiency directly affects lead time, particularly in material sourcing and delivery.

Just-in-Time Inventory: Implementing JIT inventory management ensures materials are available without excessive stock. For example, maintaining a 5-day buffer of forging materials (e.g., Inconel 718) prevents delays while minimizing storage costs. Reliable local suppliers reduce delivery times by 1-2 weeks compared to international vendors.

Supplier Coordination: Regular communication with suppliers ensures timely delivery. Providing suppliers with demand forecasts 4-6 weeks in advance allows them to prepare, reducing material lead time by 20-30%.

Material Staging: Pre-staging materials near the CNC machine reduces retrieval time. Organizing materials by job order can save 10-15 minutes per setup, especially for high-mix production environments.

Key Parameters for Machining Phases

The following table summarizes critical parameters for each machining phase to optimize lead time while maintaining quality.

| Phase | Werkzeug-Typ | Tool Diameter (mm) | Spindle Speed (RPM) | Feed Rate (mm/min) | Schnitttiefe (mm) | Step-Over (mm) |

|---|---|---|---|---|---|---|

| Aufrauen | Ball-End Mill | 12-16 (wide), 6-8 (narrow) | 8,000-12,000 | 1,200-2,000 | 2-4 | N/A |

| Semi-Finishing | Ball-End Mill | 8 | 10,000-15,000 | 800-1,500 | 1-2 | 0.8-1.2 |

| Fertigstellung | Tapered End Mill | 6-10 | 12,000-18,000 | 500-1,000 | 0.5-1 | 0.2-0.4 |

Measuring and Monitoring Lead Time

Accurate measurement of lead time is essential to identify areas for improvement. Lead time is defined as the duration from order placement to completion of the impeller for shipping.

Measurement Metrics: Track lead time in days, from order entry to final inspection. For example, a typical impeller machining process may take 10-15 days. Break down lead time into direct time (machining and assembly) and non-direct time (material sourcing, scheduling). Use software to log timestamps at each stage, enabling data-driven adjustments.

Performance Tracking: Graph lead time alongside quality metrics (e.g., defect rates) and production costs. A weekly report showing lead time trends helps identify recurring delays, such as tool setup (e.g., 2-3 hours per job) or material shortages (e.g., 1-2 days delay).

Continuous Improvement: Regularly review lead time data to refine processes. For instance, reducing setup time from 3 hours to 2 hours per job can save 5-10% of total lead time in a month.

Schlussfolgerung

Shortening lead time for compressor impeller machining requires a systematic approach, integrating optimized machining strategies, 5-axis CNC technology, streamlined process planning, automation, and efficient supply chain management. By implementing specific parameters, such as appropriate tool sizes, spindle speeds, and feed rates, manufacturers can reduce machining time while maintaining quality. Automation and digital tools further enhance efficiency, while JIT inventory and supplier coordination minimize delays. Continuous monitoring and data-driven adjustments ensure sustained improvements, enabling manufacturers to deliver high-quality impellers faster and remain competitive.