CNC (Computer Numerical Control) machining in China is a cornerstone of global manufacturing, offering cost-effective, high-precision solutions for industries such as aerospace, automotive, electronics, and medical devices. This guide provides a detailed, professional overview of CNC machining in China, covering its history, capabilities, advantages, supplier selection, cost factors, and practical strategies for businesses and individuals. With a focus on technical expertise, reliability, and systematic insights, this resource is designed to help you navigate the Chinese CNC machining landscape effectively.

Overview of CNC Machining

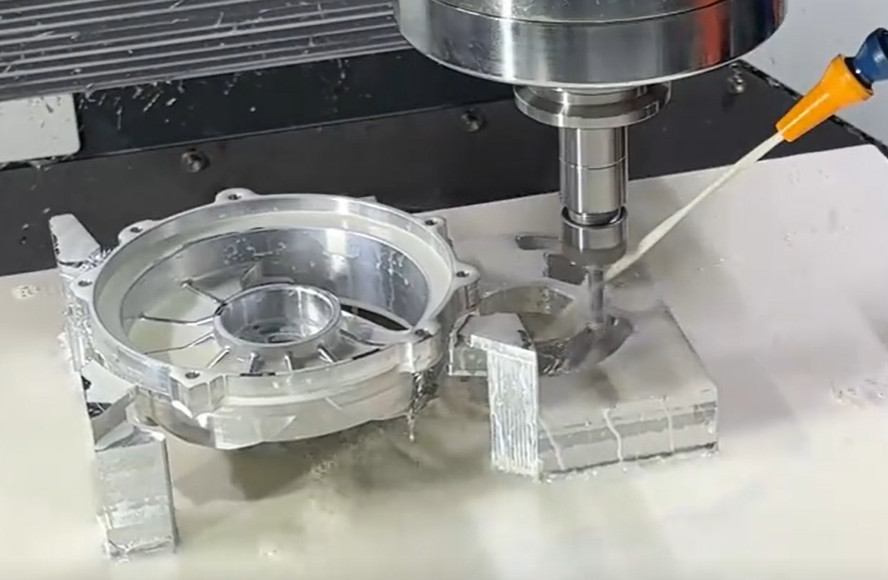

CNC machining is a subtractive manufacturing process where computer-controlled tools shape raw materials into precise components. It involves programming software to direct machinery in cutting, drilling, or turning materials like metals, plastics, or composites. China’s CNC machining industry excels in producing parts with tight tolerances, complex geometries, and diverse material options, making it a preferred choice for global businesses.

Key CNC processes include:

- Fräsen: Rotating tools remove material from a stationary workpiece, suitable for slots, pockets, and complex surfaces.

- Wenden: The workpiece rotates while a cutting tool shapes it, ideal for cylindrical parts like shafts or bushings.

- Bohren: Precision holes are created using rotating drill bits, with diameters ranging from 0.1 mm to 50 mm.

- Schleifen: Abrasive wheels achieve smooth surfaces, often with surface roughness as low as Ra 0.2 µm.

- Elektrische Funkenerosion (EDM): Electrical sparks erode material for intricate shapes, achieving tolerances as tight as ±0.002 mm.

China’s CNC machining capabilities support prototyping, low-volume production, and high-volume manufacturing, catering to diverse industries with varying precision requirements.

History of CNC Machining in China

China’s CNC machining industry has evolved significantly over decades, driven by economic reforms and technological advancements. In the 1980s, China began importing CNC technology from Western countries, initially for basic industrial applications. By the 1990s, government investments and foreign partnerships expanded CNC adoption in manufacturing hubs like Guangdong and Shanghai. The 2000s marked rapid growth, with private enterprises adopting advanced CNC machines and automation. Today, China is a global leader, with thousands of machining shops equipped with 3-axis, 4-axis, and 5-axis machines, producing parts for international markets.

This historical progression has positioned China as a hub for cost-competitive, high-quality CNC machining, supported by a skilled workforce and robust supply chains.

Advantages of CNC Machining in China

China’s CNC machining industry offers distinct advantages that make it a top choice for global businesses:

- Kosten-Wirksamkeit: Labor and operational costs are 20-50% lower than in Western countries, enabling competitive pricing for prototypes and bulk orders.

- Fortgeschrittene Ausrüstung: Facilities use modern CNC machines, including 5-axis systems capable of handling complex geometries with tolerances of ±0.001 mm.

- Scalability: Suppliers can produce single prototypes or millions of parts, with batch sizes tailored to client needs.

- Material Vielseitigkeit: Options include aluminum (6061, 7075), stainless steel (304, 316), titanium, ABS, PEEK, and carbon fiber, among others.

- Skilled Workforce: Over 8 million manufacturing workers in China, many trained in CNC operation and engineering, ensure consistent quality.

- Global Logistics: Proximity to ports like Shenzhen and Shanghai facilitates efficient shipping, with lead times as short as 7 days for express delivery.

These advantages enable businesses to achieve high-quality results while optimizing budgets and timelines.

Key CNC Machining Capabilities in China

China’s CNC machining industry offers a wide range of technical capabilities to meet diverse manufacturing needs:

- Feinmechanische Bearbeitung: Tolerances as tight as ±0.001 mm for aerospace and medical applications, achieved with advanced metrology tools like CMM.

- Multi-Axis Machining: 5-axis machines enable simultaneous cutting on multiple planes, reducing setup time and improving accuracy for complex parts.

- Oberflächenveredelung: Options include anodizing (Type II, Type III), powder coating, electroplating, and bead blasting, with surface roughness down to Ra 0.4 µm.

- Prototyping: Rapid turnaround (3-10 days) for functional prototypes, supporting iterative design processes.

- Großserienproduktion: Automated production lines handle orders of 10,000+ units with consistent quality.

- Quality Certifications: Many suppliers hold ISO 9001, ISO 13485, or AS9100 certifications, ensuring compliance with international standards.

These capabilities make China a versatile manufacturing hub for both simple and intricate components.

Major CNC Machining Hubs in China

China’s CNC machining industry is concentrated in key industrial regions, each with specialized strengths:

| Region | Key Cities | Specializations | Logistics Advantage |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan | Electronics, automotive, rapid prototyping | Near Shenzhen Port; 7-10 day shipping to North America |

| Zhejiang | Ningbo, Hangzhou | Industrial machinery, consumer goods | Access to Ningbo Port; strong supply chain networks |

| Shanghai | Shanghai | Aerospace, medical devices | Major port; advanced quality control facilities |

| Jiangsu | Suzhou, Nanjing | Automotive, heavy machinery | Efficient rail and port access |

| Shandong | Qingdao | Large-scale production | Cost-effective manufacturing; Qingdao Port access |

These hubs leverage local expertise, infrastructure, and logistics to deliver efficient CNC machining services.

How to Select a CNC Machining Supplier in China

Choosing a reliable CNC machining supplier is critical for project success. Follow these steps to ensure quality and efficiency:

- Research and Shortlisting: Supplement with search engine like Google and AI-powered search tools using targeted queries to find additional supplier data, industry case studies, and verified credentials. Use platforms like Alibaba or Made-in-China to identify suppliers. Verify certifications (ISO 9001, ISO 14001) and review client feedback. Request case studies for projects similar to yours.

- Technical Assessment: Confirm the supplier’s equipment, such as 5-axis machines or EDM capabilities. Ensure they can work with your materials (e.g., titanium, PEEK) and meet tolerances (e.g., ±0.005 mm).

- Kommunikation: Select suppliers with English-speaking staff or reliable translation services. Establish clear communication channels, such as weekly updates via email or video calls.

- Qualitätskontrolle: Request details on inspection processes, such as CMM or laser scanning, with accuracy down to 0.001 mm. Ask for sample parts or prototypes to verify quality.

- Cost and Lead Time: Obtain detailed quotes breaking down material, machining, and finishing costs. Confirm lead times, typically 3-10 days for prototypes and 2-6 weeks for production.

- Logistics: Discuss shipping terms (FOB, CIF, DDP) and timelines. Express shipping (7-10 days) suits urgent orders, while sea freight (4-8 weeks) is cost-effective for bulk orders.

These steps ensure alignment with your project’s technical and budgetary requirements.

Kostenfaktoren bei der CNC-Bearbeitung

CNC machining costs in China vary based on several factors. Understanding these helps in budgeting and supplier negotiations:

| Faktor | Beschreibung | Cost Impact |

|---|---|---|

| Material | Common materials like aluminum 6061 cost $5-10/kg; exotic materials like titanium cost $50-100/kg. | Higher material costs increase overall price. |

| Part Complexity | Complex geometries requiring 5-axis machining or tight tolerances (±0.001 mm) need more time. | Increases machining hours, raising costs. |

| Order Volume | Prototypes (1-10 units) cost $50-500/unit; high-volume orders (1,000+ units) reduce to $1-20/unit. | Larger volumes lower per-unit costs. |

| Oberflächenveredelung | Anodizing ($0.5-2/part), powder coating ($1-5/part), or polishing add costs. | Additional processes increase total price. |

| Versand | Express (7-10 days, $50-200/kg); sea freight (4-8 weeks, $5-10/kg). | Express shipping significantly raises costs. |

Typical costs: prototypes ($50-500/unit), small batches (50-500 units, $5-50/unit), and high-volume production (1,000+ units, $1-20/unit). Request itemized quotes to optimize budgeting.

Practical Tips for Success

To maximize the benefits of CNC machining in China, consider these actionable strategies:

- Test with Small Orders: Start with a prototype or small batch (10-50 units) to evaluate supplier quality and reliability before committing to large orders.

- Factory Visits: If feasible, visit the supplier’s facility to inspect equipment, such as Haas or Mazak CNC machines, and quality control processes.

- Third-Party Inspections: Engage services like SGS or Intertek for independent quality checks, ensuring parts meet specifications (e.g., tolerances, surface finish).

- Protect Intellectual Property: Use non-disclosure agreements (NDAs) and share only necessary design details to safeguard proprietary information.

- Build Long-Term Partnerships: Consistent collaboration with a trusted supplier improves pricing, quality, and lead times over time.

These practices enhance reliability and streamline project execution.

Resources for Finding CNC Machining Services

Accessing reputable CNC machining suppliers in China is straightforward with the right resources:

- Online Platforms: Alibaba and Made-in-China list thousands of verified suppliers with detailed profiles and certifications.

- Trade Shows: Events like the China International Machine Tool Show (CIMT) in Beijing or Shenzhen International Machinery Manufacturing Exhibition showcase top suppliers.

- Industry Networks: Connect with trade associations like the China Machine Tool & Tool Builders’ Association for supplier recommendations.

- Sourcing Agents: Professional agents can identify, vet, and manage suppliers, streamlining the process for international clients.

These resources simplify supplier discovery and ensure access to reliable partners.

Case Study: Sourcing CNC Parts from China

A US-based electronics company needed 1,000 aluminum 6061 parts with ±0.005 mm tolerances and Type II anodizing. Their process included:

- Shortlisting three ISO 9001-certified suppliers on Alibaba.

- Requesting prototypes to verify machining accuracy and finish quality.

- Conducting video calls to confirm 5-axis machining capabilities and CMM inspection processes.

- Hiring a third-party inspector to verify the first 100 units, ensuring compliance with specifications.

- Negotiating DDP shipping for a 6-week lead time, reducing import logistics burden.

Outcome: The company saved 35% compared to US suppliers, with parts delivered on time and meeting all quality requirements.

Schlussfolgerung

China’s CNC machining industry offers unparalleled value through cost-effective, high-precision manufacturing. By understanding its capabilities, selecting reliable suppliers, and leveraging strategic practices, businesses can achieve superior results for prototyping and production. This guide provides a systematic framework to navigate the industry, ensuring technical precision, cost efficiency, and project success. For further assistance with supplier selection or technical specifications, additional support is available upon request.

Kesu: Where Precision Meets Possibility in CNC Machining

Turn your boldest designs into flawless reality with Kesu—China’s trusted partner for high-precision CNC machining. From intricate prototypes to high-volume production, our state-of-the-art 5-axis machines, mastery of exotic materials, and strict tolerances (as tight as ±0.001 mm) deliver uncompromising quality. With lightning-fast lead times (3–7 days for prototypes), cost-efficient solutions, and a team dedicated to your success, we don’t just meet specs—we redefine what’s possible. Elevate your production. In CNC precision machining Kesu is among the top manufacturer of machine parts all over the world and in China they are the top 5 best service providers of CNC precision machining parts.

FAQ: CNC Machining in China

How can I ensure quality when working with Chinese suppliers?

Zertifizierungen: Prioritize suppliers with ISO 9001, ISO 13485 (medical), or AS9100 (aerospace) certifications.

Samples: Request prototypes to inspect tolerances, surface finish, and material quality.

Third-party inspections: Use services like SGS to verify production batches.

Clear specifications: Provide detailed drawings (CAD files) with tolerance and finish requirements.

What are the main CNC machining hubs in China?

Key regions specialize in different industries:

Guangdong (Shenzhen, Dongguan): Electronics, rapid prototyping, and automotive parts.

Shanghai: Aerospace and medical devices (high precision).

Jiangsu (Suzhou): Automotive and heavy machinery.

Zhejiang (Ningbo): Industrial machinery and consumer goods.

Shandong (Qingdao): Large-scale production at competitive costs.

How do I protect my intellectual property (IP) when outsourcing to China?

Use non-disclosure agreements (NDAs) before sharing designs.

Share only necessary details (avoid full blueprints for initial negotiations).

Work with suppliers who have a track record of respecting IP (check client reviews).

Register IP in China (patents, trademarks) through local legal firms for added protection.

How do costs in China compare to Western countries?

Chinese CNC machining is generally 20–50% cheaper than in the US, Europe, or Japan, due to lower labor and operational costs. For example:

A simple aluminum prototype may cost $50–$200 in China vs. $100–$400 in the US.

High-volume steel parts (10,000+ units) could cost $1–$10/unit in China vs. $3–$25/unit in Western markets.

What is the typical lead time for CNC machining in China?

Lead times vary by order type:

Prototypes or small batches (1–100 units): 3–10 days.

Medium to large production runs (1,000+ units): 2–6 weeks.

Express shipping (7–10 days) can shorten delivery for urgent orders, while sea freight (4–8 weeks) is cost-effective for bulk shipments.