Nickel-based alloy impellers are critical components in industries such as aerospace, oil and gas, and chemical processing due to their exceptional corrosion resistance, high-temperature strength, and durability. However, machining these alloys presents significant challenges, including work hardening, high cutting temperatures, and tool wear. This guide provides a detailed overview of the equipment requirements for machining nickel-based alloy impellers, focusing on machine tools, cutting tools, coolant systems, and process optimization. The content is structured to address technical specifications, operational considerations, and practical solutions to ensure precision and efficiency.

Material Properties of Nickel-Based Alloys

Nickel-based alloys, such as Inconel 625, Inconel 718, and Monel K-500, are characterized by their high nickel content (typically 50-70%), combined with elements like chromium, molybdenum, and Titan. These alloys exhibit:

- High tensile strength (up to 1000 MPa for Inconel 718).

- Excellent corrosion resistance in harsh environments, such as seawater and acidic conditions.

- High-temperature resistance, maintaining strength up to 700°C for alloys like IN625.

- Rapid work hardening during machining, increasing hardness by up to 20% in the cutting zone.

- Low thermal conductivity (approximately 10-15 W/m·K), leading to heat concentration at the cutting edge.

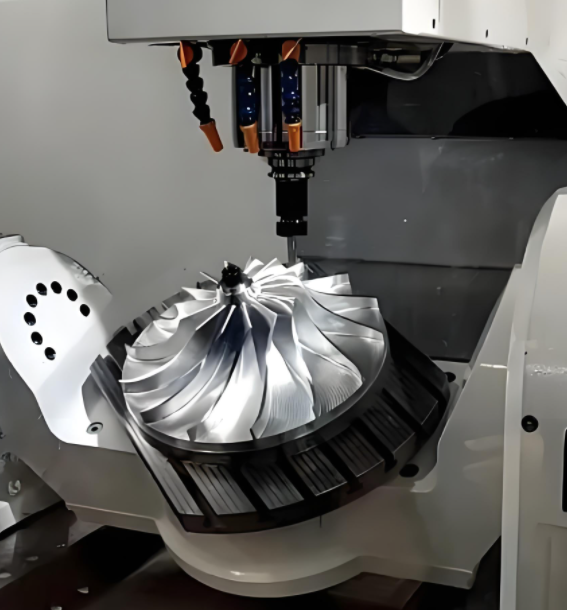

These properties necessitate specialized equipment capable of handling high cutting forces, managing heat, and preventing tool failure. The complex geometry of impellers, with curved blades and tight tolerances (often ±0.01 mm), further amplifies the need for advanced machining systems.

Machine Tool Requirements

Machining nickel-based alloy impellers requires robust, high-precision machine tools to handle the material’s toughness and geometric complexity. The following are key requirements for machine tools:

CNC-Bearbeitungszentren

Five-axis CNC machining centers are preferred for impeller machining due to their ability to access complex geometries and maintain precision. Key specifications include:

- Spindle Rigidity: A rigid spindle with a torque rating of at least 500 Nm is essential to minimize vibrations, which can cause out-of-tolerance parts or tool chatter.

- Spindeldrehzahl: Variable spindle speeds ranging from 5,000 to 15,000 rpm to accommodate both high-speed ceramic tools and lower-speed carbide tools.

- Kontrollsysteme: Advanced CNC controls (e.g., FANUC or Siemens) with high-speed data processing to maintain consistent acceleration and deceleration, preventing dwell-induced work hardening.

- Table Load Capacity: A minimum of 1000 kg to support large impellers, which can have diameters up to 1200 mm for industrial applications.

Vertical boring mills are also used for turning and drilling large impellers (up to 120” in diameter), particularly for tube sheets and flanges in nickel alloys.

Machine Stability and Vibration Control

Nickel alloys’ high cutting forces (up to 2000 N in milling operations) require machines with high structural stability. Vibration-dampening features, such as reinforced machine beds and anti-chatter systems, are critical to maintaining surface finish quality (Ra 0.8-1.6 µm) and dimensional accuracy. Hydraulic workholding systems, such as chucks and vises, should be used to ensure rigid clamping and minimize workpiece movement.

Toolpath Optimization

Programming strategies like trochoidal toolpaths are recommended to ensure consistent chip loads and reduce shock to the cutting tool. These toolpaths help maintain cutting efficiency and prevent work hardening by avoiding excessive dwell time.

Cutting Tool Requirements

The choice of cutting tools is critical due to the abrasive nature of nickel alloys and their tendency to cause rapid tool wear. The following are key considerations for cutting tools:

Tool Materials

Several tool materials are suitable for machining nickel-based alloys, each with specific advantages:

| Werkzeug Material | Eigenschaften | Anwendungen | Schnittgeschwindigkeit (m/min) |

|---|---|---|---|

| Hochgeschwindigkeitsstahl (HSS) | High toughness, suitable for interrupted cuts | Milling, threading, broaching | 5-10 |

| Carbide (Coated) | High wear resistance, moderate toughness | Turning, milling, drilling | 20-40 |

| Ceramic (SiAlON) | High-temperature resistance, high-speed capability | High-speed milling, turning | 100-300 |

| Cubic Boron Nitride (cBN) | Extreme hardness, long tool life | Turning Inconel 718, finishing | 400-600 |

HSS Tools: Used for low-speed operations (5-10 m/min) with feed rates of 0.1-0.16 mm/tooth, suitable for milling and threading due to their toughness.

Carbide Tools: Coated carbide tools (e.g., TiAlN coating) are preferred for general-purpose machining at speeds of 20-40 m/min. They offer a balance of wear resistance and cost-effectiveness.

Ceramic Tools: SiAlON ceramics are ideal for high-speed milling (up to 300 m/min) due to their ability to retain hardness at elevated temperatures (up to 1200°C). No coolant is used to avoid thermal shock.

cBN Tools: Used for precision turning of Inconel 718 at high speeds (400-600 m/min), offering up to 100% longer tool life compared to carbide tools.

Werkzeug-Geometrie

Tool geometry significantly impacts machining performance:

- Positive Rake Angle: A rake angle of 5-15° reduces cutting forces and prevents work hardening by promoting shearing rather than plowing.

- Sharp Cutting Edges: Sharp edges minimize built-up edge (BUE) formation, where chips weld to the tool, causing poor surface finish.

- Increased Nose Angle: A nose angle of 60-90° enhances edge strength, reducing notch wear at the depth of cut line.

Regular tool inspection and replacement are necessary, as nickel alloys can dull tools quickly, with tool life often ranging from 5-10 minutes for carbide tools in high-speed operations.

Coolant and Lubrication Systems

High cutting temperatures (up to 1000°C) during nickel alloy machining necessitate advanced coolant systems to manage heat and chip evacuation.

High-Pressure Coolant Systems

A coolant pressure of at least 1000 psi is mandatory to dissipate heat and clear chips from the cutting zone. High-pressure coolant reduces work hardening by lowering the temperature in the cutting area and improves tool life by up to 30%. Systems should deliver coolant directly to the cutting edge to maximize effectiveness.

Coolant Types

The choice of coolant depends on the machining operation:

- Sulfurized Oil: Used for low-speed operations like threading and heavy drilling. A high-viscosity sulfurized oil (e.g., petroleum-based cutting oil) is applied to flood the workpiece, reducing friction and preventing BUE.

- Water-Miscible Fluids: Vegetable oil-based fluids are effective for CNC machining at high metal removal rates, providing excellent heat dissipation.

- No Coolant for Ceramics: When using ceramic tools, coolant is avoided to prevent thermal shock, relying instead on the tool’s heat resistance.

For grinding operations, a solution of 25 gallons of water with 1 lb of sal soda or 50 parts water to 1 part soluble oil is recommended to manage heat and prevent corrosion.

Process Optimization and Safety Considerations

Optimizing the machining process for nickel-based alloy impellers involves careful planning to address material challenges and ensure operator safety.

Prozess-Parameter

Key machining parameters must be tailored to the alloy and operation:

| Operation | Schnittgeschwindigkeit (m/min) | Feed Rate (mm/rev or mm/tooth) | Schnitttiefe (mm) |

|---|---|---|---|

| Wenden | 20-600 (depending on tool material) | 0.1-0.3 | 0.5-2.0 |

| Fräsen | 5-300 | 0.1-0.16 | 0.5-3.0 |

| Bohren | 10-40 | 0.05-0.15 | 0.5-1.5 |

| Schleifen | 20-50 | 0.01-0.05 | 0.02-0.1 |

These parameters should be adjusted based on the specific alloy (e.g., Group A alloys like Nickel 200 are machined at lower speeds due to their gummy nature) and tool condition.

Safety and Preparation

Safety considerations include:

- Material Knowledge: Understanding the alloy’s properties, such as its tendency to work harden or react to heat, to select appropriate tools and parameters.

- Tool Inspection: Regular checks to ensure tools are sharp and free of defects, preventing catastrophic failure.

- Machine Setup: Ensuring stable fixturing (e.g., shaft fixtures for impellers) to prevent vibrations and ensure operator safety.

Non-destructive testing (e.g., ultrasonic flaw detection) should be performed on raw materials to verify integrity before machining, reducing the risk of defects in the final impeller.

Herausforderungen und Lösungen

Machining nickel-based alloy impellers presents several challenges, including work hardening, high tool wear, and heat management. Solutions include:

- Arbeitsverhärtung: Use cold-drawn, stress-relieved material to minimize initial hardness. Employ sharp tools with positive rake angles and maintain consistent cutting speeds to avoid dwell.

- Werkzeugverschleiß: Select high-quality tools (e.g., C-grade inserts or cBN) and replace them at regular intervals. Use ceramic tools for high-speed operations to extend tool life.

- Heat Management: Implement high-pressure coolant systems and optimize Schnittparameter to reduce thermal loads. For ceramic tools, operate without coolant to leverage their heat resistance.

Advanced techniques, such as chip thinning, can increase material removal rates (e.g., from 1.1 in³/min to 8.0 in³/min) without compromising tool life or part quality.

Schlussfolgerung

Machining nickel-based alloy impellers requires specialized equipment, including five-axis CNC machining centers, high-performance cutting tools, and advanced coolant systems. By understanding the material properties, optimizing process parameters, and addressing challenges like work hardening and tool wear, manufacturers can achieve high precision and efficiency. The combination of robust machine tools, appropriate tool materials, and strategic process planning ensures the production of high-quality impellers that meet the stringent demands of industries like aerospace and oil and gas.