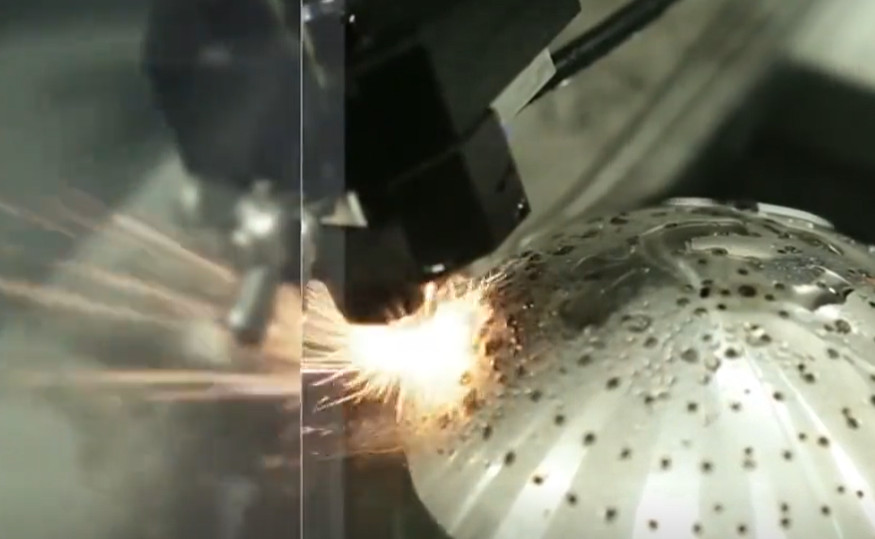

Electrical Discharge Machining (EDM) is a non-conventional machining process widely used for manufacturing complex components like centrifugal impellers, which are critical in industries such as aerospace, automotive, and energy. Centrifugal impellers, characterized by their intricate geometries, twisted blades, and narrow channels, demand high precision and surface quality. EDM is particularly suitable for such components due to its ability to machine hard materials and complex shapes without physical contact. This article outlines the four key control points for effective EDM of centrifugal impellers: process setup, machining parameters, electrode design, and post-machining inspection. Each point is detailed with technical parameters and practical considerations to ensure precision, efficiency, and reliability.

1. Process Setup

The foundation of successful EDM for centrifugal impellers lies in a meticulously planned process setup. This involves configuring the EDM machine, workpiece, and dielectric fluid system to ensure stability and precision throughout the machining process. Proper setup minimizes errors and ensures consistent material removal.

Workpiece Preparation: The centrifugal impeller, typically made from materials like stainless steel, titanium alloys, or nickel-based superalloys, must be securely fixed using a fixture to prevent movement during machining. The fixture should maintain a stable position with a maximum displacement tolerance of ±0.01 mm to avoid vibrations that could affect accuracy. The workpiece surface should be cleaned to remove contaminants, ensuring optimal electrical conductivity.

Dielectric Fluid System: EDM requires a dielectric fluid, such as deionized water or hydrocarbon oil, to insulate the gap between the electrode and workpiece and to flush away eroded particles. The dielectric fluid must maintain a resistivity of 10–20 MΩ·cm for deionized water or a flash point above 100°C for oil-based fluids. A filtration system with a particle removal efficiency of at least 95% is essential to keep the fluid clean, as contaminated fluid can increase electrode wear and reduce surface quality.

Machine Calibration: The EDM machine, whether a sinker or wire EDM type, must be calibrated to maintain a spark gap of 0.01–0.05 mm. The servo-controlled feed system should ensure a consistent feed rate, typically 0.1–0.5 mm/min, to maintain the gap and prevent short-circuiting. For centrifugal impellers, a 5-axis EDM machine is often preferred due to the complex geometry, allowing precise control over electrode positioning.

Environmental Control: The machining environment should be maintained at a temperature of 20–25°C and humidity below 50% to prevent thermal expansion of the workpiece or electrode, which could lead to dimensional inaccuracies. A stable power supply with voltage fluctuations below ±5% is critical to ensure consistent spark generation.

2. Machining Parameters

Machining parameters directly influence the material removal rate (MRR), electrode wear rate (EWR), and surface roughness in EDM of centrifugal impellers. Key parameters include pulse current, pulse-on time, pulse-off time, and voltage. Optimizing these parameters is critical for achieving the desired balance between efficiency and precision.

Pulse Current (I): The pulse current determines the energy of each spark. For centrifugal impellers, a pulse current of 10–25 A is typically used. Lower currents (10–15 A) are suitable for finishing operations to achieve a surface roughness of Ra 0.8–1.6 µm, while higher currents (20–25 A) are used for roughing to maximize MRR, typically 50–100 mm³/min.

Pulse-On Time (t_i): This parameter defines the duration of each spark. For impeller machining, pulse-on times range from 50–200 µs. Shorter pulse-on times (50–100 µs) are used for finishing to minimize thermal damage and achieve a surface finish of Ra 1.0 µm or better. Longer pulse-on times (150–200 µs) are used for roughing to increase material removal but may result in a surface roughness of Ra 2.5–3.2 µm.

Pulse-Off Time (t_o): The pulse-off time allows the dielectric fluid to flush debris and cool the machining zone. A pulse-off time of 50–150 µs is recommended. Shorter pulse-off times (50–80 µs) are used for high-speed machining, while longer times (100–150 µs) are preferred for finishing to ensure stable sparking and reduced electrode wear.

Voltage: The gap voltage, typically 40–80 V, controls the spark gap size and stability. For impellers with narrow channels, a lower voltage (40–50 V) is used to maintain a smaller spark gap (0.01–0.03 mm), ensuring precision in intricate areas. Higher voltages (60–80 V) are used for roughing to increase the spark gap and MRR.

| Parameter | Aufrauen | Fertigstellung |

|---|---|---|

| Pulse Current (A) | 20–25 | 10-15 |

| Pulse-On Time (µs) | 150–200 | 50-100 |

| Pulse-Off Time (µs) | 50–80 | 100–150 |

| Voltage (V) | 60–80 | 40–50 |

Parameter Optimization: For centrifugal impellers, parameters must be adjusted based on material properties. For example, titanium alloys require lower pulse currents (10–15 A) to minimize thermal damage, while stainless steel can tolerate higher currents (20–25 A). Experimental data, such as those from Taguchi L16 orthogonal arrays, indicate that spindle speed and feed rate are critical for surface roughness, with optimal settings at maximum spindle speed (e.g., 10,000 RPM) and minimum feed per tooth (e.g., 0.01 mm/tooth).

3. Electrode Design

The electrode is a critical component in EDM, as it directly shapes the impeller’s geometry. For centrifugal impellers, electrode design must account for the complex blade profiles, narrow channels, and high precision requirements. Common electrode materials include graphite, copper, and tungsten, each selected based on conductivity and wear resistance.

Electrode Material Selection: Graphite is widely used due to its high conductivity and low wear rate, typically 0.1–0.3% EWR. Copper is preferred for fine details due to its excellent conductivity but has a higher wear rate (0.5–1.0%). Tungsten is used for machining superalloys, offering a wear rate as low as 0.05% but at a higher cost. For impellers, graphite electrodes are often chosen for their balance of cost and performance.

Electrode Geometry: The electrode must be a precise negative of the desired impeller geometry. For closed impellers, multiple electrodes may be required to machine different sections, such as blades and hubs. The electrode design should account for a spark gap of 0.01–0.05 mm, with a tolerance of ±0.005 mm for critical features like blade edges. For wire EDM, a wire diameter of 0.1–0.25 mm is used to achieve fine cuts in narrow channels.

Partition Schemes: For complex impellers, a partition scheme divides the machining process into segments. For example, one scheme may involve machining the hub and blades separately, using a graphite electrode for the hub and a wire electrode for the blades. Motion simulation and interference checking are conducted to ensure the electrode path avoids collisions, particularly in narrow channels with blade heights of 0.5–1.0 inches.

Electrode Fabrication: Electrodes are typically machined using CNC-Fräsen to achieve a surface finish of Ra 0.8 µm and dimensional accuracy of ±0.01 mm. For intricate impeller designs, a 5-axis CNC machine is used to create twisted blade profiles. The electrode must be inspected for dimensional accuracy before use, as deviations can lead to overcuts or incomplete machining.

4. Post-Machining Inspection

Post-machining inspection ensures that the centrifugal impeller meets dimensional and surface quality requirements. This step is critical for verifying the accuracy of blade profiles, channel widths, and surface finish, which directly impact aerodynamic performance.

Prüfung der Abmessungen: Coordinate Measuring Machines (CMM) are used to verify dimensions with an accuracy of ±0.002 mm. Key measurements include blade thickness (typically 0.5–2.0 mm), channel width (0.5–1.5 mm), and hub diameter (up to 5 inches). Deviations beyond ±0.01 mm may require rework, as they can affect impeller balance and performance.

Oberflächenqualität: Surface roughness is measured using a profilometer, targeting Ra 0.8–1.6 µm for finished impellers. EDM typically achieves a smooth finish, but excessive sparking can result in a “blasted” texture with Ra >3.2 µm. Visual inspection under 10x magnification checks for microcracks or recast layers, which should be less than 0.01 mm thick to avoid fatigue failure.

Material Integrity: Non-destructive testing (NDT), such as ultrasonic or dye penetrant testing, is used to detect subsurface defects. For superalloy impellers, X-ray inspection ensures no internal voids or inclusions are present. The heat-affected zone (HAZ) should be minimal, typically less than 0.02 mm, to maintain material properties.

Functional Testing: The impeller is tested for balance at speeds up to 14,000 RPM, ensuring vibration levels remain below 0.1 mm/s. Aerodynamic performance is verified using computational fluid dynamics (CFD) or physical testing in a pump or turbine setup to confirm flow rates and pressure ratios meet design specifications.

| Inspection Parameter | Target Value | Measurement Method |

|---|---|---|

| Blade Thickness | 0.5–2.0 mm | CMM |

| Oberflächenrauhigkeit | Ra 0,8-1,6 µm | Profilometer |

| Heat-Affected Zone | <0.02 mm | X-ray/Ultrasonic |

| Vibration Level | <0.1 mm/s | Dynamic Balancing |

Schlussfolgerung

Effective EDM of centrifugal impellers requires meticulous control over four key points: process setup, machining parameters, electrode design, and post-machining inspection. By optimizing workpiece preparation, dielectric fluid systems, and machine calibration, the process setup ensures stability. Precise machining parameters, such as pulse current and voltage, balance efficiency and surface quality. Electrode design, tailored to the impeller’s complex geometry, ensures accurate material removal. Finally, rigorous inspection verifies dimensional accuracy, surface finish, and material integrity. These control points, supported by precise parameters and systematic processes, ensure high-quality centrifugal impellers that meet the stringent demands of industries like aerospace and energy.