Hastelloy, a nickel-based superalloy, is widely used in industries such as aerospace, chemical processing, and petrochemical due to its exceptional corrosion resistance and high-temperature strength. Machining Hastelloy impellers, which are critical components in turbines and pumps, requires precision and expertise due to the material's toughness, low machinability, and complex geometries. This article provides a detailed comparison of modern UG (Unigraphics) programming and traditional programming methods for machining Hastelloy impellers, focusing on technical processes, parameters, and practical considerations to achieve high precision and efficiency.

Overview of Hastelloy Impeller Machining

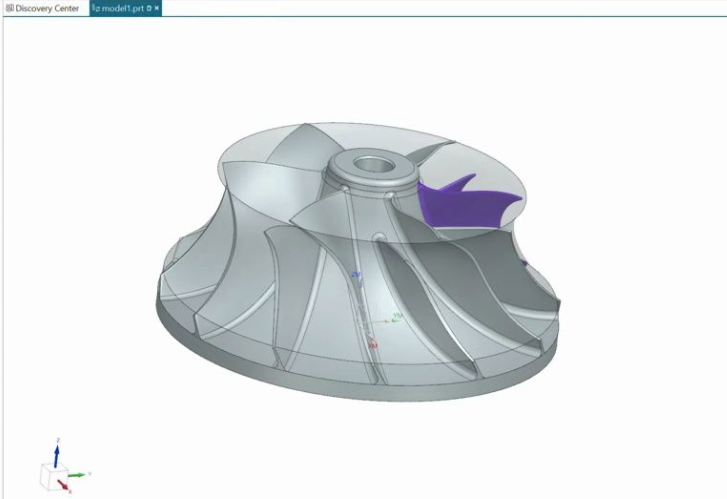

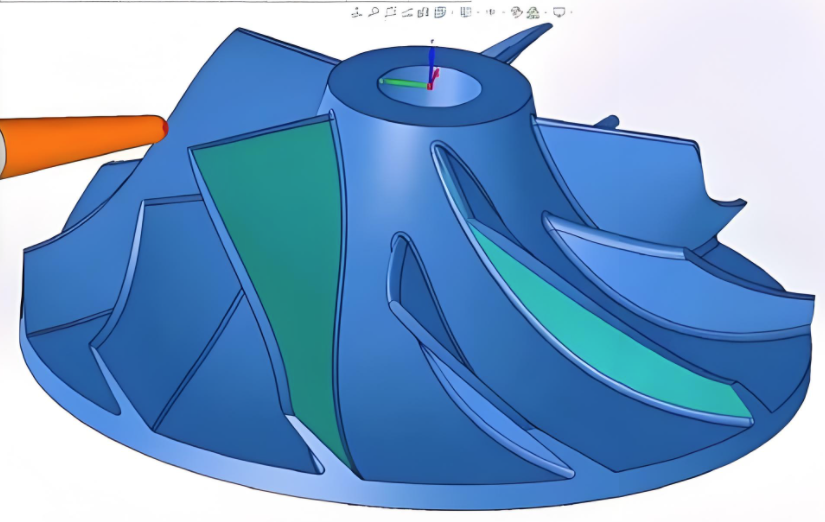

Hastelloy impellers are integral components in high-performance systems, featuring complex geometries such as twisted blades, narrow flow channels, and rounded corners. These components demand high precision to meet aerodynamic and mechanical performance requirements. Machining Hastelloy is challenging due to its high strength, work-hardening tendencies, and low thermal conductivity, which can lead to tool wear and surface quality issues. Both modern UG programming and traditional programming aim to address these challenges, but they differ significantly in approach, tools, and outcomes.

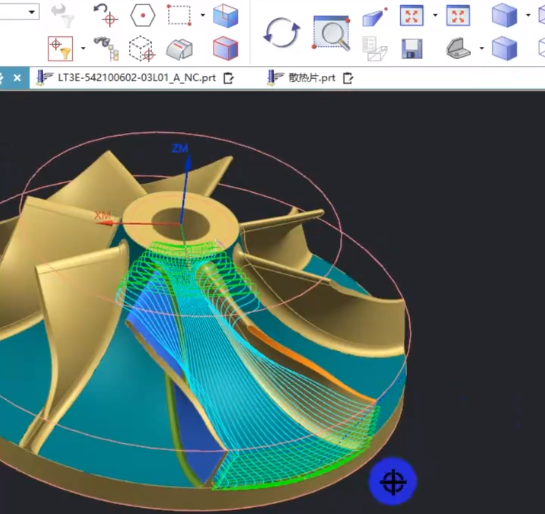

Modern UG programming leverages Siemens NX software, integrating CAD/CAM/CAE functionalities to streamline design, toolpath generation, and machining simulation. Traditional programming, often manual or based on simpler CAM systems, relies heavily on operator expertise and basic G-code programming. The comparison below explores these methods across key aspects of impeller machining.

Material Properties of Hastelloy and Machining Implications

Hastelloy alloys, such as C-276, C-22, and X, are nickel-chromium-molybdenum-based superalloys with specific mechanical properties that impact machining:

- High Strength: Hastelloy has a tensile strength of approximately 690-1000 MPa, requiring robust cutting tools and rigid machine setups.

- Niedrige Wärmeleitfähigkeit: Approximately 7-10 W/m·K, leading to heat concentration at the cutting zone, accelerating tool wear.

- Arbeitsverhärtung: Rapid work hardening during machining necessitates sufficient chip loads to cut beneath the hardened layer.

- Korrosionsbeständigkeit: Resistant to acids and high temperatures, but its gummy and abrasive nature challenges tool life and surface finish.

These properties require precise control of cutting parameters, tool selection, and programming strategies to achieve dimensional accuracy and surface quality. UG programming addresses these through advanced simulation and toolpath optimization, while traditional programming relies on operator adjustments and predefined G-code.

Modern UG Programming for Hastelloy Impeller Machining

UG programming, part of Siemens NX, is a comprehensive CAD/CAM/CAE system designed for advanced manufacturing. It offers a unified platform for designing impeller models, generating toolpaths, and simulating machining processes, making it suitable for complex Hastelloy impeller production.

Key Features of UG Programming

UG programming provides several advantages for machining Hastelloy impellers:

- 3D Model Integration: UG uses a 3D master model, enabling seamless updates to toolpaths when design changes occur. This reduces reprogramming time compared to traditional methods.

- Multi-Axis Machining: Supports 2.5- to 5-axis machining, critical for impeller geometries with twisted blades and narrow channels. For example, 5-axis machining centers with X-axis stroke of 900 mm, Y-axis 600 mm, Z-axis 550 mm, and C-axis rotation (0°-360°) are commonly used.

- Toolpath Optimization: Generates uniform toolpaths with consistent chip loads, reducing tool wear. Trochoidal toolpaths are often employed to manage Hastelloy’s abrasiveness.

- Simulation und Verifizierung: Virtual machining tests predict errors, such as tool collisions or interference, ensuring process reliability before actual cutting.

- High-Speed Machining: UG supports high-speed machining with cutting speeds of 20-50 m/min and feed rates of 0.05-0.15 mm/rev for Hastelloy, minimizing heat buildup.

UG Programming Process

The UG programming process for Hastelloy impellers involves several steps:

- Model Creation: A 3D impeller model is built using UG’s CAD module, defining the rotary body, blade profiles, and flow channel curves.

- Toolpath Generation: The CAM module generates toolpaths, aligning the Z-axis with the impeller’s rotational axis to minimize programming complexity. For example, a 5-axis toolpath may use a 6 mm ball-end mill for roughing and a 3 mm mill for finishing.

- Simulation: UG simulates the cutting process, verifying tool trajectories and detecting potential interferences, particularly in narrow channels where blade depth exceeds 8 times the tool diameter.

- Nachbearbeitung: Converts toolpaths into machine-specific G-code, compatible with CNC systems like Siemens 840D.

- Machining Execution: The CNC machine executes the program, with operators monitoring for tool wear and surface finish.

For Hastelloy, UG programming typically uses ceramic or carbide tools. For instance, whisker-reinforced ceramic inserts (e.g., Sandvik 670 grade) are used for roughing at 150-200 m/min, while positive-rake carbide inserts are used for finishing at 30-50 m/min to achieve surface roughness (Ra) of 0.8-1.6 µm.

Traditional Programming for Hastelloy Impeller Machining

Traditional programming involves manual G-code creation or basic CAM systems, relying heavily on operator expertise. It is often used for simpler parts or in shops with limited access to advanced software.

Key Features of Traditional Programming

Traditional programming has distinct characteristics:

- Manual G-Code: Operators write G-code based on 2D drawings or basic CAM outputs, requiring deep knowledge of machining processes and Hastelloy’s behavior.

- Limited Automation: Lacks integrated simulation, increasing the risk of errors like tool collisions or incorrect toolpaths.

- Basic Toolpaths: Typically uses linear or circular interpolation, less suited for complex impeller geometries.

- Operator Dependency: Relies on skilled operators to adjust parameters during machining, such as feed rates (0.1-0.2 mm/rev) and cutting speeds (20-40 m/min).

- Auswahl der Werkzeuge: Often uses cobalt roughers or carbide inserts, with manual adjustments for tool wear and work hardening.

Traditional Programming Process

The traditional process for machining Hastelloy impellers includes:

- Drawing Interpretation: Operators interpret 2D or 3D drawings to define machining sequences.

- G-Code Creation: Manual coding or basic CAM systems generate G-code, specifying tool movements and parameters.

- Machine Setup: Operators set up the CNC machine, aligning the workpiece and selecting tools (e.g., ¾-inch ceramic inserts for roughing).

- Bearbeitung: The machine executes the G-code, with operators monitoring and adjusting for issues like burrs or tool chipping.

- Inspektion: Post-machining inspection ensures dimensional accuracy and surface finish, often requiring manual rework.

Traditional programming struggles with Hastelloy’s properties, as manual adjustments may not consistently achieve the required surface finish (Ra 1.6-3.2 µm) or dimensional tolerances (±0.01 mm).

Comparison of UG and Traditional Programming

The following table compares key aspects of UG and traditional programming for Hastelloy impeller machining:

| Aspekt | UG Programming</ th> | Traditional Programming |

|---|---|---|

| Toolpath Generation | Automated, optimized for 5-axis machining with trochoidal paths | Manual or basic CAM, limited to linear/circular paths |

| Simulation | Integrated virtual machining to detect errors | No simulation, relies on operator expertise |

| Präzision | High (tolerances ±0.005 mm, Ra 0.8-1.6 µm) | Moderate (tolerances ±0.01 mm, Ra 1.6-3.2 µm) |

| Effizienz | Short setup and reprogramming time | Longer setup and manual adjustments |

| Tool Wear Management | Optimized toolpaths reduce wear | Frequent manual tool changes |

Practical Considerations in Hastelloy Impeller Machining

Several practical considerations arise when machining Hastelloy impellers, affecting both UG and traditional programming:

- Werkzeugverschleiß: Hastelloy’s abrasiveness causes rapid tool wear. UG programming mitigates this through optimized toolpaths, while traditional methods require frequent tool changes.

- Oberfläche: Achieving Ra 0.8-1.6 µm is critical for aerodynamic performance. UG’s simulation ensures consistent finishes, while traditional methods may result in burrs or defects.

- Interference: Narrow flow channels and twisted blades risk tool interference. UG’s 5-axis capabilities and simulation reduce this risk, unlike traditional methods.

- Steifigkeit der Maschine: Both methods require rigid machines (e.g., 50-taper CNCs) to handle Hastelloy’s high cutting forces.

Recommended Machining Parameters

The following table provides typical parameters for machining Hastelloy impellers:

| Parameter | Roughing (Ceramic Tools) | Finishing (Carbide Tools) |

|---|---|---|

| Schnittgeschwindigkeit (m/min) | 150-200 | 30-50 |

| Vorschubgeschwindigkeit (mm/Umdrehung) | 0.1-0.2 | 0.05-0.15 |

| Schnitttiefe (mm) | 1.0-2.0 | 0.1-0.5 |

| Coolant | Dry (ceramic) or high-pressure coolant (carbide) | High-pressure coolant |

Schlussfolgerung

Modern UG programming offers significant advantages over traditional programming for machining Hastelloy impellers. Its integration of 3D modeling, multi-axis toolpaths, and simulation ensures higher precision, reduced tool wear, and shorter production cycles. Traditional programming, while cost-effective for simpler parts, struggles with Hastelloy’s complex geometries and material properties, relying heavily on operator skill. For high-performance impellers in demanding industries, UG programming is the preferred choice, providing a systematic and reliable approach to achieving stringent quality requirements.