Turbomolecular pumps (TMPs) are vital in industries like semiconductors, aerospace, and vacuum technology, where their impellers—complex, high-speed rotating components—require exceptional precision in manufacturing. The intricate blade geometries and tight tolerances of TMP impellers demand advanced CNC machining techniques to ensure performance and reliability. This article provides a detailed, technical guide on controlling CNC machining precision specifically for turbomolecular pump impellers, focusing on systematic methods, specific parameters, and practical approaches to achieve high accuracy.

Understanding Precision Requirements for TMP Impellers

The impeller, often referred to as the rotor in TMPs, is the core component responsible for creating ultra-high vacuum conditions through rapid rotation, typically exceeding 50,000 RPM. TMP impellers feature multi-stage blades with twisted, curved surfaces, requiring dimensional tolerances as tight as ±0.01 mm and surface finishes with roughness values (Ra) of 0.2–0.4 µm. Precision in machining impellers directly affects pump efficiency, vacuum quality, and dynamic stability. Key specifications include:

- Blade Geometry: Complex, aerodynamic profiles with angles precise to ±0.1° to optimize gas flow.

- Material: Typically Aluminiumlegierungen like AL6061-T6 for lightweight and machinability.

- Dynamic Balance: Must achieve balance quality grade G2.5 (ISO 1940) to minimize vibration.

Achieving these standards requires advanced CNC equipment, precise programming, and stringent quality control. The following sections detail the critical factors and methods for controlling machining precision for TMP impellers.

Machine Tool Selection and Calibration

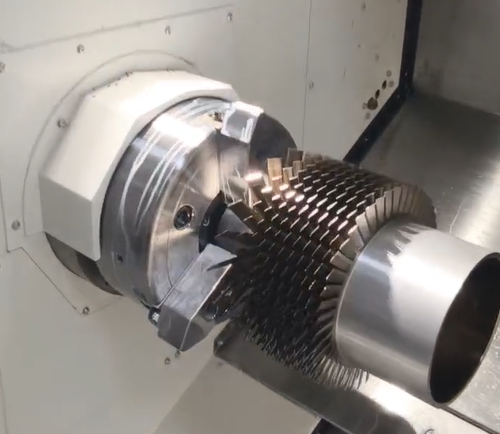

Selecting the right CNC machine is critical for machining TMP impellers due to their complex geometries. 5-axis CNC machining centers are ideal for handling the multi-angle blade profiles.

Machine Specifications:

- Spindle Precision: Runout must be below 0.002 mm to ensure accurate tool positioning.

- Axis Resolution: Sub-micron resolution (0.0001 mm) is necessary for ultra-precision tasks.

- Thermal Stability: Cooling systems should maintain temperature variations within ±0.5°C to minimize thermal expansion errors.

Calibration Procedures:

Regular calibration ensures machine accuracy, including:

- Laser Interferometry: Measures axis positioning accuracy, achieving repeatability within ±0.001 mm.

- Ballbar Testing: Detects geometric errors in multi-axis movements, ensuring circularity errors below 0.003 mm.

- Spindle Alignment: Adjusted to maintain concentricity within 0.001 mm.

Maintenance: Routine checks on linear guides and bearings prevent errors up to 0.01 mm caused by wear. For example, a 5-axis machine like the DMG MORI DMU 50, with a spindle speed of 14,000 RPM and positioning accuracy of ±0.002 mm, is well-suited for impeller machining.

Tool Selection and Optimization

Cutting tools are pivotal in achieving precision for TMP impellers, particularly when machining aluminum alloys.

Material des Werkzeugs:

- Carbide Tools: Used for roughing and semi-finishing due to their durability and wear resistance.

- Diamond-Coated Tools: Employed for finishing to achieve surface roughness of Ra 0.2 µm.

Werkzeug-Geometrie:

- High-Helix End Mills: 3–5 flutes reduce vibration and ensure smooth cutting for blade surfaces.

- Ball Nose Cutters: Ideal for curved blade profiles, maintaining dimensional accuracy within ±0.005 mm.

Tool Parameters:

| Operation | Werkzeug-Typ | Spindle Speed (RPM) | Feed Rate (mm/min) | Schnitttiefe (mm) |

|---|---|---|---|---|

| Roughing (Blade Groove) | Carbide End Mill | 8,000–10,000 | 1,200–1,800 | 0.5–1.0 |

| Finishing (Blade Surface) | Diamond-Coated Ball Nose | 10,000–14,000 | 400–700 | 0.03–0.08 |

Tool Maintenance: Tools are inspected using presetters to ensure length and diameter accuracy within ±0.002 mm. Worn tools can increase surface roughness by 0.3 µm, impacting impeller performance.

CNC-Programmierung und Simulation

Precise CNC programming is essential for TMP impellers due to their intricate blade designs. CAM software like Siemens NX or Mastercam generates optimized toolpaths.

Programming Techniques:

- 5-Axis Toolpaths: Simultaneous 5-axis machining ensures blade angles are precise to ±0.01 mm.

- Adaptive Clearing: Reduces cutting forces, limiting tool deflection errors to below 0.002 mm.

- Helical Interpolation: Ensures smooth transitions in curved surfaces, minimizing step-over errors to 0.001 mm.

Simulation and Verification: Tools like VERICUT simulate toolpaths to prevent collisions or overcutting, ensuring deviations remain within ±0.05 mm. Auto-Diff functions compare toolpaths to CAD models, verifying dimensional accuracy. For custom impellers, reverse engineering with 3D scanners reconstructs CAD models with ±0.03 mm accuracy.

Material Selection and Handling

Material choice is critical for TMP impellers, with AL6061-T6 being the standard due to its balance of strength and machinability.

Materialeigenschaften:

- AL6061-T6: Tensile strength of 310 MPa, density of 2.7 g/cm³, ideal for high-speed rotation.

- Alternative Materials: Titanium alloys (e.g., Ti-6Al-4V) for specialized applications, though harder to machine.

Material Handling:

- Clamping: Vacuum chucks or custom fixtures secure impellers without deformation, maintaining positional accuracy within ±0.002 mm.

- Pre-Machining: Blanks are turned to ±0.1 mm on CNC lathes to reduce stress during final machining.

Erwägungen: Material inclusions can cause tool chatter, leading to surface errors up to 0.015 mm. Ultrasonic testing ensures material integrity before machining.

Environmental Control and Stability

Environmental factors like temperature and vibration significantly impact machining precision for impellers.

Temperaturkontrolle:

- Workshop Conditions: Maintain 20±1°C to limit thermal expansion errors to 0.001 mm/m.

- Coolant Systems: High-pressure coolant (50–70 bar) stabilizes temperatures, reducing thermal drift to below 0.002 mm.

Vibration Control:

- Machine Foundation: Concrete bases with dampers reduce vibrations to below 0.1 µm amplitude.

- Spindle Monitoring: Sensors maintain vibration levels below 0.4 µm to prevent blade surface imperfections.

Example: A 0.8°C temperature fluctuation during impeller machining caused a 0.004 mm error, corrected by implementing a closed-loop cooling system.

Quality Control and Inspection

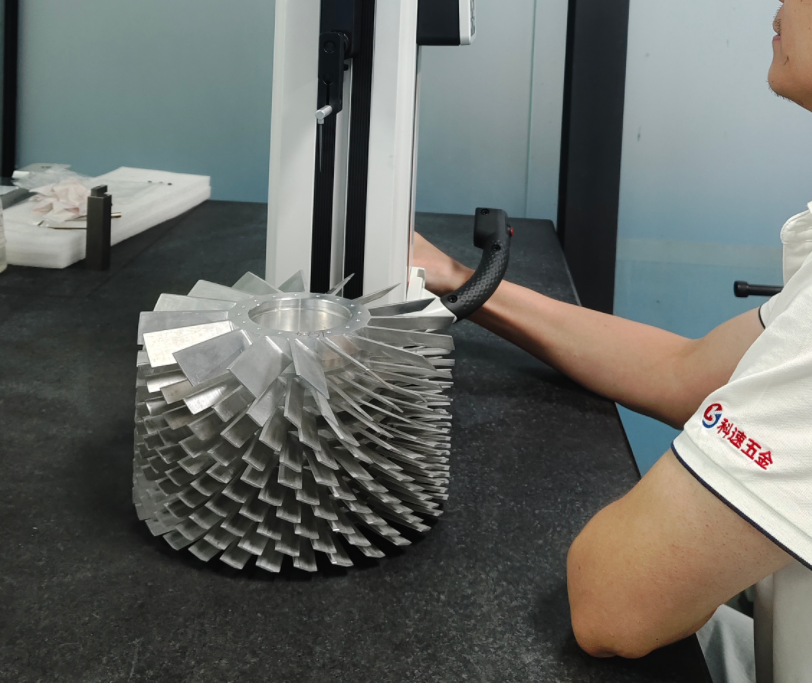

Robust quality control ensures TMP impellers meet stringent specifications.

Inspection Methods:

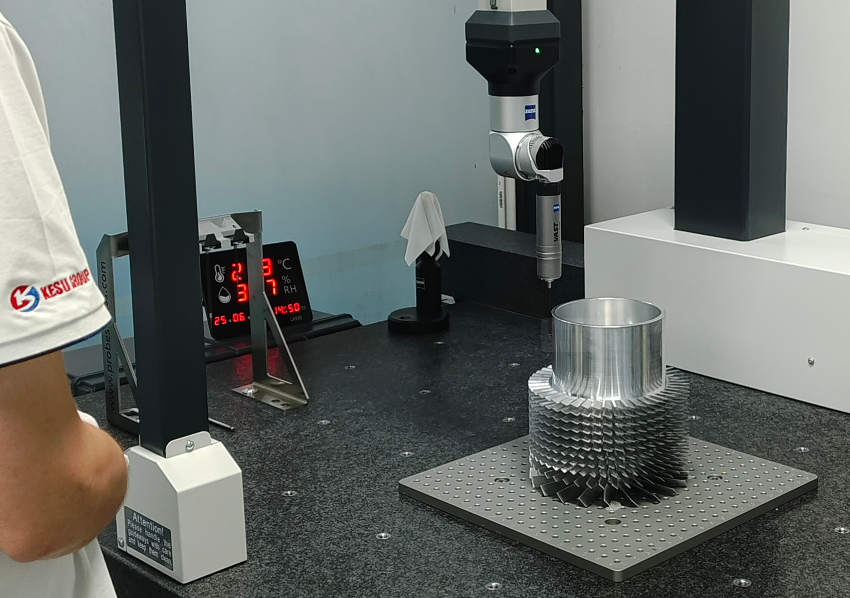

- Coordinate Measuring Machines (CMM): Verify tolerances within ±0.002 mm using 0.001 mm resolution probes.

- Surface Profilometers: Ensure Ra values of 0.2–0.4 µm for blade surfaces.

- Dynamisches Auswuchten: Balance impellers to G2.5 grade, minimizing residual unbalance to 0.01 g·mm.

Inspection Parameters:

| Merkmal | Toleranz (mm) | Surface Roughness (Ra, µm) | Inspektionsmethode |

|---|---|---|---|

| Blade Profile | ±0.01 | 0.2–0.4 | CMM, Profilometer |

| Hub Diameter | ±0.005 | 0.3–0.5 | CMM |

Verification: Software like Geomagic Qualify compares machined impellers to CAD models, ensuring deviations are within ±0.05 mm. Non-conforming parts trigger toolpath or setup adjustments.

Practical Considerations for Impeller Machining

Several practical issues can affect CNC machining precision for TMP impellers:

- Werkzeugverschleiß: Continuous machining increases roughness by 0.1–0.2 µm, requiring tool changes every 10–15 hours.

- Vibrations: High-speed machining can cause blade profile errors up to 0.01 mm, mitigated by dampened tool holders.

- Setup Errors: Misaligned fixtures can introduce errors of 0.02 mm, emphasizing the need for skilled operators.

Addressing these requires regular training, real-time monitoring, and vibration analysis to maintain precision.

Schlussfolgerung

Controlling CNC machining precision for turbomolecular pump impellers demands a systematic approach, integrating advanced 5-axis machines, optimized tooling, precise programming, proper material handling, environmental stability, and rigorous inspection. By achieving tolerances of ±0.01 mm, surface roughness of Ra 0.2–0.4 µm, and dynamic balance, manufacturers can produce high-performance IMPs for ultra-high vacuum applications. This guide provides a technical, reliable framework for consistent machining success.