Impeller dynamic balancing is a critical process in ensuring the smooth operation of rotating machinery such as fans, pumps, and turbines. Unbalanced impellers can lead to excessive vibration, noise, and premature wear of components, reducing the lifespan and efficiency of equipment. Achieving high precision in dynamic balancing requires a systematic approach, incorporating advanced equipment, precise measurement techniques, and optimized procedures. This article provides a comprehensive guide to enhancing the precision of impeller dynamic balancing, focusing on technical methodologies, equipment specifications, and procedural best practices.

Understanding Dynamic Balancing and Its Importance

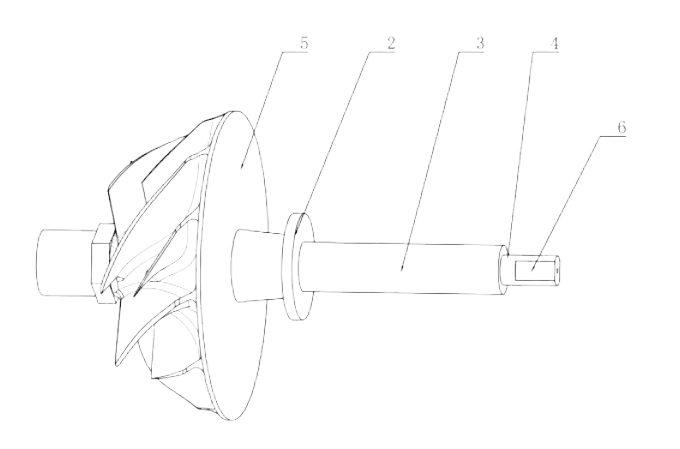

Dynamic balancing involves correcting the mass distribution of a rotating impeller to minimize vibration caused by uneven centrifugal forces. Unlike static balancing, which addresses imbalance in a single plane, dynamic balancing corrects imbalances in two or more planes, ensuring smooth operation at high speeds. The precision of this process directly impacts the performance, reliability, and longevity of rotating machinery.

Key factors influencing balancing precision include the accuracy of measurement systems, the quality of balancing equipment, and the operator’s expertise. High-precision balancing reduces vibration amplitudes, typically measured in micrometers (µm) or millimeters per second (mm/s), to within acceptable standards such as ISO 1940-1, which specifies balance quality grades (e.g., G2.5 for industrial fans, requiring residual unbalance below 2.5 mm/s).

Selecting High-Precision Balancing Equipment

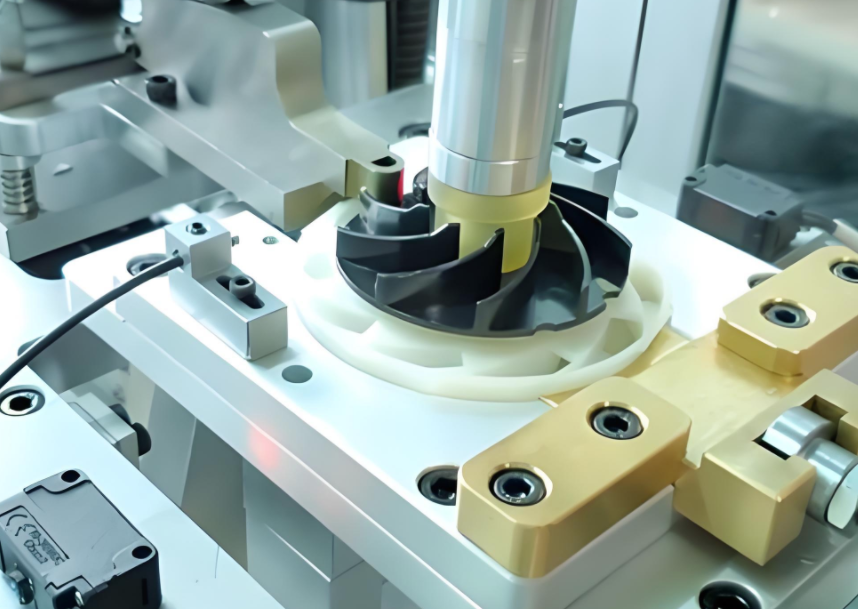

The choice of balancing equipment is foundational to achieving high precision. Modern dynamic balancing machines are equipped with advanced sensors, data acquisition systems, and software for real-time analysis. Key equipment parameters include:

- Sensitivity: Machines should detect residual unbalance as low as 0.1 g·mm/kg to meet stringent balance quality requirements.

- Speed Range: Balancing machines must operate within the impeller’s operational speed range, typically 500–10,000 RPM, to simulate real-world conditions.

- Load Capacity: Equipment should accommodate impeller sizes and weights, ranging from small pump impellers (0.5–5 kg) to large turbine rotors (up to 500 kg).

- Data Acquisition: High-resolution sensors (e.g., laser vibrometers or accelerometers) with sampling rates above 10 kHz ensure accurate vibration measurements.

Hard-bearing balancing machines are preferred for high-precision applications due to their rigidity and ability to measure unbalance forces directly. Soft-bearing machines, while more flexible, may introduce errors at higher speeds due to suspension dynamics. Calibration of equipment to standards such as ISO 2953 ensures measurement reliability.

Optimizing Measurement Techniques

Accurate measurement of unbalance is critical to achieving precision. The following techniques enhance measurement accuracy:

- Vibration Analysis: Use accelerometers to measure vibration amplitude and phase angle at multiple points on the impeller. Typical vibration thresholds for high-precision balancing are below 0.5 mm/s RMS (Root Mean Square).

- Phase Measurement: Precise phase angle determination, typically within ±2°, allows accurate identification of unbalance locations. Phase errors can lead to incorrect weight placement, reducing balancing effectiveness.

- Multi-Plane Balancing: For compleximpellers with multiple blades or stages, balancing in two or more planes is necessary. Software algorithms calculate correction weights for each plane, minimizing cross-coupling effects.

- Umweltkontrolle: Conduct balancing in a controlled environment to minimize external vibrations (e.g., from nearby machinery) and temperature fluctuations, which can affect sensor accuracy.

Regular calibration of sensors and verification of measurement systems against known standards ensure consistent results. For example, a reference rotor with a known unbalance (e.g., 10 g·mm) can be used to validate machine accuracy before testing.

Procedural Best Practices for Dynamic Balancing

A structured balancing procedure enhances precision by minimizing errors and ensuring repeatability. The following steps outline a systematic approach:

- Preparation: Inspect the impeller for physical defects (e.g., cracks, material inconsistencies) that could affect balance. Clean the impeller to remove debris, as even small particles (e.g., 0.1 g) can cause measurable unbalance.

- Mounting: Secure the impeller on the balancing machine using precision fixtures. Misalignment or loose mounting can introduce errors, increasing residual unbalance by up to 20%.

- Initial Run: Perform a baseline run at the impeller’s operating speed to measure initial unbalance. Record vibration amplitude and phase data for both planes.

- Weight Correction: Add or remove material based on software calculations. Common methods include adding balance weights (e.g., 0.5–5 g) or material removal via drilling or grinding. Ensure corrections are made within tolerances (e.g., ±0.01 g).

- Verification: Conduct a final run to confirm residual unbalance meets the target grade (e.g., G2.5 or G1.0 for high-precision applications). Repeat corrections if necessary.

Documentation of each step, including vibration data and correction weights, ensures traceability and facilitates quality control. Automated balancing systems can streamline this process by integrating measurement and correction in real time.

Überlegungen zu Material und Design

The impeller’s material and design significantly affect balancing precision. Key considerations include:

- Material Uniformity: Variations in material density (e.g., ±0.1 g/cm³ in cast impellers) can introduce inherent unbalance. Use high-quality materials or apply post-casting treatments like homogenization to minimize inconsistencies.

- Blade Symmetry: Asymmetrical blade designs, common in complex impellers, require precise modeling to predict unbalance. Finite element analysis (FEA) can simulate mass distribution and guide balancing corrections.

- Manufacturing Tolerances: Tighten tolerances during machining (e.g., ±0.01 mm for blade thickness) to reduce initial unbalance. Computer numerical control (CNC) machining ensures consistent geometry.

Pre-balancing inspection using coordinate measuring machines (CMM) can verify dimensional accuracy, reducing the need for extensive corrections during dynamic balancing.

Common Issues and Solutions

While not all balancing processes encounter significant obstacles, certain issues can compromise precision if not addressed. The table below summarizes common problems and their solutions:

| Issue | Beschreibung | Lösung |

|---|---|---|

| Inaccurate Vibration Measurements | Sensor misalignment or external vibrations lead to erroneous data. | Calibrate sensors regularly and isolate the balancing machine from external vibrations using damping pads. |

| Residual Unbalance | Persistent unbalance after corrections, often due to incorrect weight placement. | Verify phase angle accuracy and use iterative corrections with smaller weight increments (e.g., 0.05 g). |

Addressing these issues requires rigorous quality control and operator training to ensure consistent results.

Advanced Techniques for Enhanced Precision

For applications requiring ultra-high precision (e.g., aerospace turbines), advanced techniques can further improve balancing outcomes:

- Laser-Based Balancing: Laser systems measure unbalance with sub-micron accuracy and apply corrections via precise material removal. These systems achieve residual unbalance below 0.05 g·mm/kg.

- Real-Time Monitoring: Continuous vibration monitoring during operation allows dynamic adjustments, particularly for impellers operating at variable speeds.

- Software Optimization: Advanced algorithms, such as genetic algorithms or neural networks, optimize weight placement by analyzing complex unbalance patterns across multiple planes.

These techniques require specialized equipment and expertise but are essential for meeting stringent standards in high-performance applications.

Quality Control and Standards Compliance

Adhering to international standards ensures balancing precision and operational reliability. Key standards include:

- ISO 1940-1: Defines balance quality grades (e.g., G2.5, G1.0) based on residual unbalance and rotor speed. For example, a 10 kg impeller at 3,000 RPM requires residual unbalance below 8 g·mm for G2.5.

- ISO 11342: Provides guidelines for balancing flexible rotors, applicable to impellers with deformable blades.

- API 610: Specifies balancing requirements for centrifugal pumps, mandating dynamic balancing for impellers above 1,800 RPM.

Regular audits of balancing procedures and equipment calibration records ensure compliance with these standards. Certification by third-party organizations can further validate the process.

Operator Training and Expertise

Operator skill is a critical factor in achieving high-precision balancing. Comprehensive training programs should cover:

- Equipment Operation: Familiarity with balancing machine interfaces and software for accurate data interpretation.

- Vibration Analysis: Understanding of vibration spectra and phase data to diagnose unbalance causes.

- Safety Protocols: Safe handling of high-speed rotating equipment to prevent accidents during balancing.

Certification programs, such as those offered by the Vibration Institute, enhance operator competence and ensure consistent results.

Case Study: Balancing a Centrifugal Pump Impeller

Consider a centrifugal pump impeller with the following specifications:

| Parameter | Value |

|---|---|

| Gewicht | 15 kg |

| Operating Speed | 3,600 RPM |

| Balance Quality Grade | G2.5 |

| Initial Unbalance | 50 g·mm |

Using a hard-bearing balancing machine with 0.1 g·mm/kg sensitivity, the initial run revealed vibration amplitudes of 1.2 mm/s RMS. After two correction cycles, adding 2.5 g and 1.8 g weights at specific phase angles, the residual unbalance was reduced to 7 g·mm, achieving a vibration level of 0.3 mm/s RMS, well within the G2.5 standard. This example demonstrates the importance of iterative corrections and precise equipment in achieving high-precision balancing.

Schlussfolgerung

Improving the precision of impeller dynamic balancing requires a combination of advanced equipment, optimized measurement techniques, and rigorous procedural controls. By selecting high-sensitivity balancing machines, implementing accurate vibration and phase measurements, and adhering to international standards, manufacturers can achieve residual unbalance levels that meet or exceed industry requirements. Material and design considerations, along with operator training, further enhance balancing outcomes. For critical applications, advanced techniques like laser-based balancing and real-time monitoring offer additional precision. By following a systematic approach, as outlined in this article, engineers can ensure smooth, reliable, and efficient operation of rotating machinery.