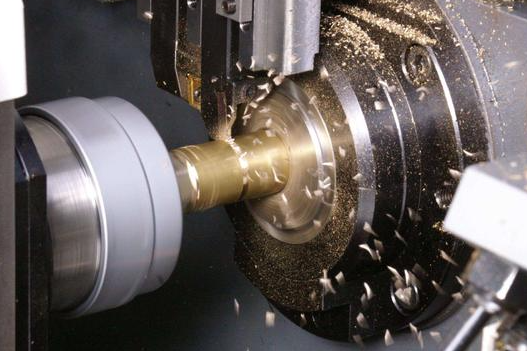

Turbo rotor impellers are critical components in turbochargers and aerospace engines, requiring high precision and efficiency in machining to meet performance and durability standards. Turning, as a primary machining process, plays a pivotal role in achieving the desired geometry and surface finish. This article outlines systematic methods to enhance turning efficiency for turbo rotor impeller machining, focusing on practical techniques, detailed parameters, and professional considerations to ensure reliability and technical accuracy.

Optimizing Tool Selection and Geometry

Selecting appropriate cutting tools is fundamental to improving turning efficiency. Turbo rotor impellers are typically made from high-strength materials such as titanium alloys, stainless steel, or nickel-based superalloys, which demand tools with specific properties to withstand high temperatures and mechanical stresses.

Material des Werkzeugs: Carbide tools with coatings like TiAlN or AlCrN are preferred for their wear resistance and thermal stability. For example, a TiAlN-coated carbide insert can operate at cutting speeds of 80-120 m/min for titanium alloys, extending tool life by 20-30% compared to uncoated tools.

Werkzeug-Geometrie: Use inserts with a positive rake angle (5-10°) to reduce cutting forces and heat generation. A nose radius of 0.4-0.8 mm balances surface finish and tool strength. For finishing operations, a smaller nose radius (0.2-0.4 mm) can enhance surface quality, achieving Ra values of 0.8-1.6 µm.

Tool Clamping: Ensure rigid clamping systems to minimize vibration. Hydraulic or precision collet chucks provide better stability than standard mechanical chucks, reducing tool deflection by up to 15% during high-speed turning.

Machine Tool Setup and Stability

The stability of the machine tool setup directly impacts turning efficiency. Turbo rotor impellers often feature complex geometries, such as thin-walled blades and deep grooves, which require robust setups to prevent chatter and ensure dimensional accuracy.

Machine Selection: Use CNC lathes with high spindle rigidity and thermal stability. Machines with a spindle power of 15-30 kW and a maximum speed of 4000-6000 RPM are suitable for impeller machining. For example, a CNC lathe with a C-axis capability enables precise contouring of complex impeller profiles.

Workholding: Employ customized fixtures to secure the impeller. Vacuum chucks or soft jaws tailored to the impeller’s geometry reduce deformation in thin-walled sections. A clamping force of 500-1000 N is typically sufficient for small to medium-sized impellers (100-200 mm diameter).

Vibration Control: Install dampening systems, such as tuned mass dampers, to reduce vibrations. Maintain a tool overhang of less than 4 times the tool diameter to minimize deflection. For instance, a 12 mm diameter tool should have an overhang of no more than 48 mm.

Cutting Parameters Optimization

Optimizing cutting parameters is critical to balancing productivity and tool life. The following parameters are tailored for turning turbo rotor impellers made from titanium alloys, a common material in high-performance applications.

| Parameter | Aufrauen | Fertigstellung |

|---|---|---|

| Schnittgeschwindigkeit (m/min) | 60-100 | 100-150 |

| Vorschubgeschwindigkeit (mm/Umdrehung) | 0.15-0.3 | 0.05-0.1 |

| Schnitttiefe (mm) | 1.0-2.5 | 0.2-0.5 |

Schnittgeschwindigkeit: For titanium alloys, a cutting speed of 60-100 m/min for roughing and 100-150 m/min for finishing ensures efficient material removal while maintaining tool integrity. Higher speeds may cause excessive heat, reducing tool life by 25-40%.

Vorschubgeschwindigkeit: A feed rate of 0.15-0.3 mm/rev for roughing maximizes material removal rates, while 0.05-0.1 mm/rev for finishing ensures a smooth surface. Adjusting feed rates based on real-time tool wear monitoring can improve efficiency by 10-15%.

Schnitttiefe: Use a depth of cut of 1.0-2.5 mm for roughing to remove material quickly. For finishing, a depth of 0.2-0.5 mm achieves tight tolerances (±0.01 mm) and minimizes residual stresses.

Coolant and Lubrication Strategies

Effective coolant and lubrication strategies are essential to manage heat and chip evacuation during turning, especially for high-temperature alloys used in turbo rotor impellers.

Coolant Type: Use high-pressure coolant (70-100 bar) to improve chip breaking and reduce thermal loads. Water-based emulsions with 5-10% concentration are effective for titanium and nickel alloys, reducing cutting temperatures by 20-30% compared to dry machining.

Coolant Delivery: Direct coolant jets at the tool-workpiece interface to maximize cooling efficiency. Through-tool coolant systems deliver fluid precisely, reducing tool wear by up to 15%. For example, a flow rate of 20-30 L/min is suitable for medium-sized impellers.

Chip Management: Continuous chips can clog the machining area, reducing efficiency. Use chip breakers on inserts and adjust coolant pressure to ensure short, segmented chips. This can reduce downtime for chip removal by 10-20%.

Process Monitoring and Quality Control

Real-time monitoring and quality control ensure consistent turning performance and adherence to tight tolerances, which are critical for turbo rotor impellers.

In-Process Monitoring: Use sensors to monitor cutting forces, vibrations, and tool wear. For instance, a force sensor detecting a 10% increase in cutting force can signal the need for tool replacement, preventing defects. Vibration thresholds should be set below 2 µm/s to avoid chatter.

Prüfung der Abmessungen: Employ in-machine probing systems to measure critical dimensions, such as blade thickness and hub diameter, with an accuracy of ±0.005 mm. This reduces the need for offline inspections, saving 5-10 minutes per part.

Oberflächenqualität: Use profilometers to measure surface roughness, targeting Ra values of 0.8-1.6 µm for functional surfaces. Regular calibration of measuring equipment ensures repeatability within ±0.002 mm.

Tool Path Programming and CAM Integration

Efficient tool path programming using Computer-Aided Manufacturing (CAM) software enhances turning precision and reduces cycle times for complex impeller geometries.

Tool Path Strategies: Use trochoidal tool paths for roughing to reduce cutting forces and heat buildup. For finishing, employ constant-engagement-angle tool paths to maintain consistent chip loads, improving surface finish by 10-15%.

CAM Software: Software like SurfMill or hyperMILL supports five-axis turning, enabling precise machining of twisted blades. For example, a five-axis CNC lathe with CAM integration can reduce cycle times by 20% compared to three-axis systems.

Simulation: Run virtual machining simulations to detect potential collisions and optimize tool paths. This can prevent costly errors, saving up to 5% of total machining time.

Material-Specific Considerations

Different impeller materials require tailored turning approaches to maximize efficiency while maintaining quality.

| Material | Schnittgeschwindigkeit (m/min) | Vorschubgeschwindigkeit (mm/Umdrehung) | Tool Coating |

|---|---|---|---|

| Titan-Legierung | 60-120 | 0.05-0.3 | TiAlN |

| Rostfreier Stahl | 100-200 | 0.1-0.4 | AlCrN |

| Nickel Alloy | 40-80 | 0.05-0.2 | TiCN |

Titan-Legierungen: Low thermal conductivity requires lower cutting speeds (60-120 m/min) and high-pressure coolant to prevent work hardening. A feed rate of 0.05-0.3 mm/rev minimizes heat-affected zones.

Rostfreier Stahl: Higher cutting speeds (100-200 m/min) are feasible due to better machinability. Use AlCrN-coated tools to handle abrasive wear.

Nickel Alloys: These materials are prone to work hardening, so use lower speeds (40-80 m/min) and sharp tools to maintain edge integrity.

Operator Training and Process Standardization

Skilled operators and standardized processes are critical to sustaining turning efficiency over time.

Operator Training: Train operators on CNC programming, tool setup, and troubleshooting. A trained operator can reduce setup times by 10-15% and identify issues like tool wear before they impact quality.

Standard Operating Procedures (SOPs): Develop SOPs for tool changes, machine calibration, and quality checks. For example, an SOP mandating tool inspection every 50 parts can prevent unexpected failures, improving uptime by 5%.

Documentation: Maintain detailed records of machining parameters and outcomes. This enables continuous improvement, with data-driven adjustments reducing cycle times by up to 10% over time.

Maintenance and Equipment Upkeep

Regular maintenance of machine tools and peripherals ensures consistent performance and prevents downtime.

Preventive Maintenance: Schedule spindle and bearing inspections every 1000 hours of operation. Lubricate moving parts weekly to reduce friction-related wear by 10-20%.

Tool Condition Monitoring: Use tool life management systems to track insert wear. Replace tools after 80-100 minutes of cutting time for titanium alloys to maintain efficiency.

Coolant System Maintenance: Clean coolant tanks monthly to prevent contamination, which can reduce coolant effectiveness by 15%. Monitor coolant concentration daily to ensure optimal performance.

Schlussfolgerung

Improving turning efficiency for turbo rotor impeller machining requires a systematic approach, integrating optimized tool selection, precise machine setups, tailored cutting parameters, effective coolant strategies, and robust quality control. By addressing material-specific needs, leveraging advanced CAM programming, and ensuring operator training and equipment maintenance, manufacturers can achieve significant gains in productivity and quality. Implementing these methods with detailed parameters ensures reliable, repeatable results, meeting the stringent demands of turbocharger and aerospace applications.