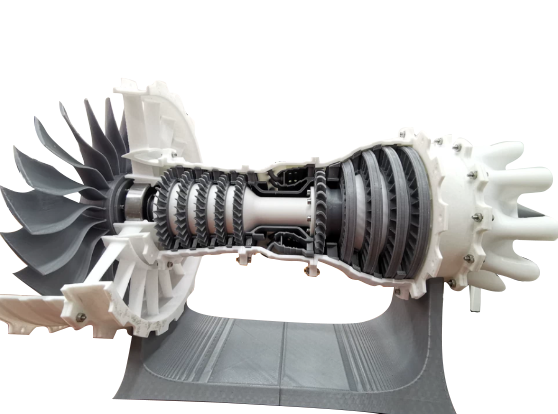

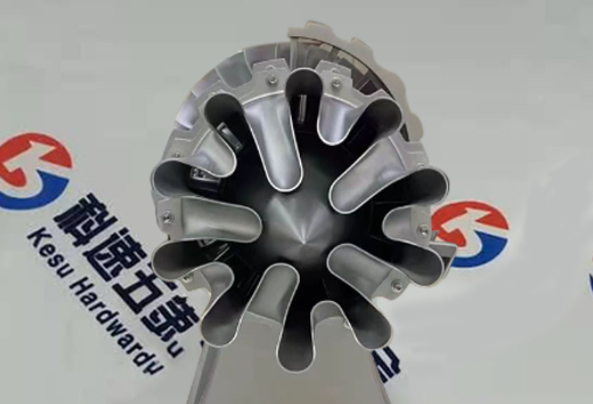

Aero-engine turbine blades, typically made from nickel-based superalloys or titanium alloys, are machined under demanding conditions that accelerate tool wear. This wear affects machining precision, surface quality, and production costs. The following sections outline a systematic, experience-based approach to address tool wear, incorporating specific parameters and practical solutions to enhance tool life and machining efficiency. The focus is on technical methods grounded in professional expertise, avoiding speculative or innovative concepts.

Tool Wear Mechanisms

Tool wear in turbine blade machining arises from interactions between the cutting tool and workpiece under high temperatures, pressures, and speeds. Common wear mechanisms include abrasive wear, adhesive wear, diffusion wear, and thermal fatigue. Nickel-based superalloys, such as Inconel 718, have high hardness (400–450 HV) and low thermal conductivity (11–15 W/m·K), generating cutting temperatures up to 1000°C. Titanium alloys, like Ti-6Al-4V, exhibit strong chemical affinity with tool materials, leading to adhesive wear. These conditions typically limit tool life to 20–60 minutes in high-speed machining.

Abrasive wear results from hard carbide particles in the workpiece eroding the tool surface. Adhesive wear occurs when workpiece material bonds to the tool, forming a built-up edge. Diffusion wear, prevalent at high temperatures, involves atomic exchange between tool and workpiece, weakening the cutting edge. Thermal fatigue, caused by cyclic heating and cooling, leads to cracking, particularly in interrupted cuts. Recognizing these mechanisms guides the selection of appropriate tools and machining strategies.

Selecting Optimal Tool Materials

The choice of tool material significantly impacts wear resistance. Common materials for turbine blade machining include cemented carbide, cubic boron nitride (CBN), and polycrystalline diamond (PCD). Each material suits specific workpiece properties and machining conditions, as summarized below.

| Werkzeug Material | Härte (HV) | Thermal Conductivity (W/m·K) | Application | Typical Tool Life (min) |

|---|---|---|---|---|

| Cemented Carbide | 1500–1800 | 50–80 | Superalloy machining | 20–40 |

| CBN | 3000–4000 | 100–200 | High-speed superalloy machining | 40–60 |

| PCD | 7000–8000 | 500–2000 | Titanium alloy machining | 50–80 |

Cemented carbide tools with fine-grain substrates (0.5–1.0 µm) offer a balance of toughness and hardness for general-purpose machining. CBN tools are ideal for high-speed machining of superalloys at cutting speeds of 200–300 m/min, resisting abrasive and thermal wear. PCD tools excel in titanium alloy machining due to their high hardness and low reactivity, though their cost limits widespread use. Matching tool material to workpiece properties is critical for minimizing wear.

Applying Advanced Tool Coatings

Coatings reduce friction, enhance thermal stability, and prevent adhesion. Common coatings include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC). TiAlN coatings, with hardness of 3300–3500 HV and oxidation resistance up to 800°C, are effective for superalloy machining. DLC coatings, with a friction coefficient of 0.1–0.2, minimize adhesive wear in Titanlegierungen.

Physical vapor deposition (PVD) coatings, applied at 2–5 µm thickness, maintain edge sharpness and extend tool life by 30–50% compared to uncoated tools (e.g., at 150 m/min, 0.1 mm/rev, 0.5 mm depth of cut). Multi-layer coatings, such as TiAlN/TiSiN, provide enhanced thermal and wear resistance. Coating integrity should be inspected every 10–15 cycles using optical microscopy to detect delamination or wear, ensuring consistent performance.

Optimizing Cutting Parameters

Cutting parameters—speed, feed rate, depth of cut, and tool geometry—directly affect tool wear. For nickel-based superalloys, recommended parameters include a cutting speed of 100–200 m/min, feed rate of 0.05–0.15 mm/rev, and depth of cut of 0.2–0.5 mm. Exceeding 250 m/min increases thermal wear, while speeds below 50 m/min prolong contact time, causing mechanical wear.

Tool geometry adjustments, such as a positive rake angle (5–10°) and honed edge radius (20–30 µm), reduce cutting forces and edge chipping. Climb milling, compared to conventional milling, lowers thermal loads by 15–20%, extending tool life. Real-time monitoring of cutting forces (500–1000 N) and temperatures using sensors allows dynamic parameter adjustments to prevent excessive wear.

Effective Coolant and Lubrication Techniques

Coolants and lubricants manage cutting temperatures and reduce friction. High-pressure coolant systems (70–100 bar) enhance chip evacuation and lower tool-workpiece friction in superalloy machining. Water-based emulsions (8–10% oil) maintain temperatures below 600°C. For titanium alloys, minimum quantity lubrication (MQL) at 10–50 ml/h reduces thermal cracking and environmental impact.

Cryogenic cooling with liquid nitrogen (-195°C) can extend tool life by 20–30% in superalloy machining by minimizing thermal wear. However, it requires precise delivery to avoid tool embrittlement. Coolant flow rates of 10–15 L/min for high-pressure systems ensure effective heat dissipation, with adjustments based on machining conditions.

Enhancing Machining Processes

Advanced machining processes reduce tool wear. High-speed machining (HSM) with CBN tools at 200–300 m/min minimizes machining time but requires precise control to limit thermal wear. Ultrasonic-assisted machining (UAM) with 20–40 kHz vibrations reduces cutting forces by 10–15%, extending tool life by up to 25%. Hybrid machining, combining milling and grinding, improves surface integrity, reducing abrasive wear.

Tool path optimization, such as trochoidal milling, minimizes abrupt directional changes, reducing mechanical stress. Computer-aided manufacturing (CAM) software simulates tool paths to ensure uniform load distribution, extending tool life by 10–20%. Regular tool inspection, targeting flank wear widths of 0.2–0.3 mm, ensures timely replacement.

Tool Condition Monitoring and Maintenance

Tool condition monitoring (TCM) systems track cutting forces (500–1500 N), vibrations (10–50 µm amplitude), and acoustic emissions to detect wear thresholds (e.g., flank wear width of 0.3 mm). Machine learning models predict tool life with 85–90% accuracy, enabling proactive maintenance. Regular regrinding of carbide tools every 15–20 cycles with a diamond wheel (100–150 µm grit) restores edge geometry. Tools should be stored in a dry, controlled environment (20–25°C) to prevent coating degradation.

Practical Implementation Example

A manufacturer machining Inconel 718 turbine blades adopted PVD TiAlN-coated carbide tools, high-pressure coolant (80 bar), and optimized parameters (150 m/min, 0.1 mm/rev, 0.3 mm depth of cut). Tool life increased from 25 to 40 minutes, reducing replacement costs by 30%. TCM systems detected wear early, preventing surface defects. This integrated approach highlights the effectiveness of combining material selection, coatings, and process optimization.

Schlussfolgerung

Addressing tool wear in aero-engine turbine blade machining involves a systematic combination of tool material selection, coatings, optimized cutting parameters, effective cooling, advanced processes, and condition monitoring. By applying these technical solutions with precise parameters, manufacturers can extend tool life, improve surface quality, and reduce costs, ensuring reliable and efficient production of high-performance turbine blades.