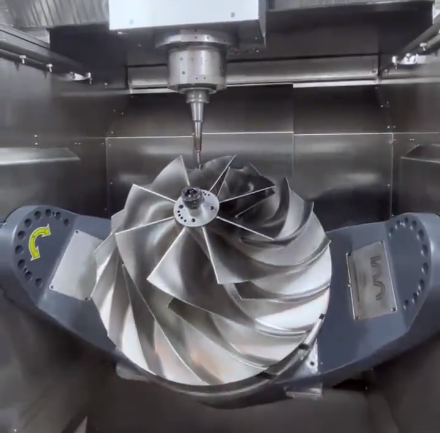

Machining axial flow impellers requires precision and efficiency due to their complex geometry, which includes twisted blades, thin-walled structures, and deep flow channels. Optimizing the utilization rate of milling consumables—such as cutting tools, tool holders, and coolant—reduces costs, minimizes waste, and enhances machining performance. This guide provides a systematic approach to achieving these goals, focusing on tool selection, machining strategies, and parameter optimization, grounded in technical expertise and practical experience.

Understanding Axial Flow Impeller Machining Requirements

Axial flow impellers are critical components in turbomachinery, used in applications like pumps, compressors, and turbines. Their design features blades with significant twist, closely spaced geometry, and thin profiles, which demand high geometric accuracy and surface quality. The machining process typically involves 5-axis CNC milling to handle the complex, free-form surfaces. Key requirements include:

- Geometric Precision: Blades must maintain tight tolerances to ensure aerodynamic performance.

- Oberflächenqualität: Smooth surfaces reduce turbulence and improve efficiency.

- Material Challenges: Impellers are often made from materials like titanium, stainless steel, or aluminum, which vary in machinability.

- Tool Longevity: Consumables must withstand high cutting forces and wear to maintain cost-effectiveness.

Optimizing consumables utilization involves balancing tool life, machining time, and material removal rates (MRR) while minimizing tool wear and breakage.

Selecting Appropriate Cutting Tools

Tool selection is critical for optimizing consumables utilization. The right tools reduce wear, improve surface quality, and enhance machining efficiency. Considerations include tool material, geometry, and coating.

Material des Werkzeugs: Carbide tools are preferred for their durability and ability to handle high cutting speeds. For titanium impellers, coated carbide tools with high-temperature resistance are ideal. High-speed steel (HSS) tools may be used for softer materials like aluminum but wear faster.

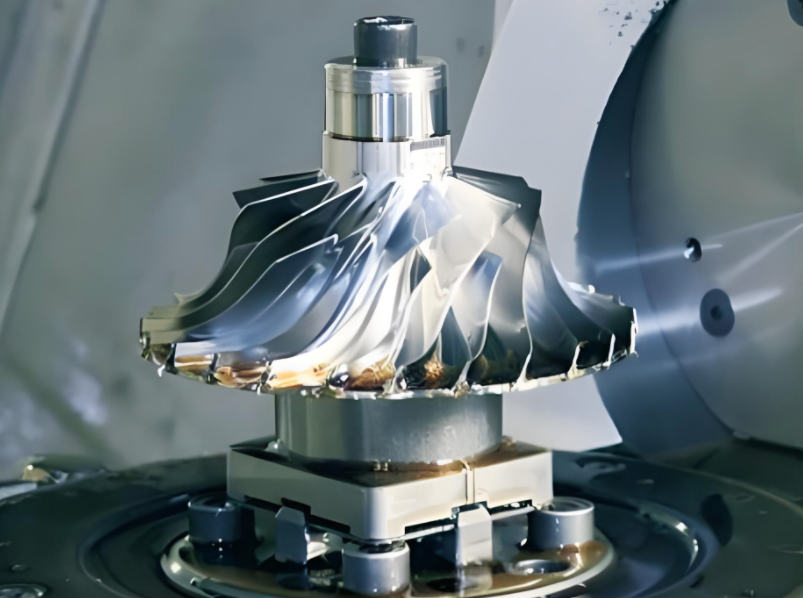

Werkzeug-Geometrie: Ball-end mills are suitable for finishing due to their ability to machine curved surfaces, while flat-end mills are effective for roughing. Tapered ball-end mills enhance rigidity for deep channel milling. For example, a 6 mm ball-end mill with a 0.5 mm step-over and 0.05 mm depth of cut can achieve a surface roughness (Ra) of 0.2–0.4 μm.

Tool Coating: Coatings like titanium aluminum nitride (TiAlN) reduce friction and heat, extending tool life. For stainless steel impellers, AlTiN coatings are effective due to their thermal stability.

Tool Holder Selection: Modular tool holders, such as collet chuck or side-fixed holders, provide flexibility and rigidity. Collet chuck holders ensure high clamping force but may loosen under heavy chip loads, so side-fixed holders are preferred for roughing.

| Werkzeug-Typ | Application | Recommended Parameters |

|---|---|---|

| Ball-End Mill | Fertigstellung | 0.05 mm depth of cut, 0.5 mm step-over, 3000 rpm |

| Flat-End Mill | Aufrauen | 15 mm depth of cut, 20% step-over, 2.4 m/min feed rate |

| Tapered Ball-End Mill | Deep Channel Milling | 0.1 mm depth of cut, 3 mm step-over, 56 m/min cutting speed |

Optimizing Machining Strategies

Machining axial flow impellers typically involves three phases: roughing, semi-finishing, and finishing. Each phase requires specific strategies to maximize consumables efficiency.

Roughing: The goal is to remove bulk material quickly. Trochoidal milling is effective for roughing due to its ability to maintain uniform tool wear. For example, using a 10 mm flat-end mill with a 15 mm axial depth of cut and 20% step-over can reduce machining time while preserving tool life. Dividing deep flow channels into multiple layers with varying tool diameters (larger for wider sections, smaller for narrow sections) prevents tool overload.

Semi-Finishing: This phase uniforms the material margin for finishing. A multi-path milling strategy with a constant axial depth of cut (e.g., 0.1 mm) minimizes tool deflection and ensures consistent material removal. Using a 6 mm ball-end mill with a 0.5 mm step-over prepares the surface for final finishing.

Finishing: Finishing requires high precision to achieve the desired surface quality. Flank milling or point milling with 5-axis CNC machines ensures accurate blade profiles. A 6 mm ball-end mill with a 0.05 mm depth of cut, 0.5 mm step-over, and 0.9 m/min feed rate can achieve a surface roughness of 0.2–0.4 μm. Rotational abrasive flow machining (RAFM) can further refine surfaces, reducing Ra to 0.2 μm for titanium impellers.

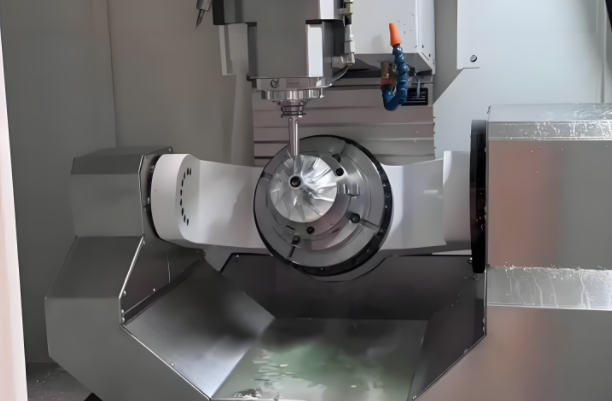

Tool Path Planning: Advanced CAM software, such as hyperMILL, optimizes tool paths to avoid collisions and reduce machining time. Plunge roughing is an alternative for deep pockets, using rigid tools to minimize vibration. For example, a 3+2 roughing strategy maximizes rigidity, allowing faster material removal.

Optimizing Machining Parameters

Machining parameters—cutting speed, feed rate, depth of cut, and step-over—directly impact consumables utilization. Proper optimization balances MRR with tool life.

Schnittgeschwindigkeit: Higher cutting speeds increase MRR but accelerate tool wear. For titanium, a cutting speed of 56 m/min is effective for finishing, while 100 m/min suits aluminum roughing. Use manufacturer-recommended speeds for specific materials.

Vorschubgeschwindigkeit: A feed rate of 0.9 m/min for finishing and 2.4 m/min for roughing optimizes tool life and surface quality. High feed milling with low depth of cut (e.g., 0.1 mm) and high feed per revolution reduces heat generation.

Schnitttiefe: Light axial depths of cut (0.05–0.1 mm for finishing, 15 mm for roughing) reduce tool stress. For deep channels, multiple passes with incremental depths prevent tool breakage.

Step-Over: A step-over of 0.5 mm (9% of tool diameter) for finishing ensures smooth surfaces, while 20% of tool diameter for roughing maximizes material removal. Excessive step-over increases residual height, degrading surface quality.

| Phase | Schnittgeschwindigkeit (m/min) | Feed Rate (m/min) | Schnitttiefe (mm) | Step-Over (% of Tool Diameter) |

|---|---|---|---|---|

| Aufrauen | 100 | 2.4 | 15 | 20 |

| Semi-Finishing | 80 | 1.5 | 0.1 | 10 |

| Fertigstellung | 56 | 0.9 | 0.05 | 9 |

Managing Consumables Wear and Costs

Effective management of tool wear and consumables costs is essential for optimization. Strategies include:

Tool Wear Monitoring: Use sensors to monitor chip formation and cutting forces. Real-time feedback allows adjustments to feed rates or depths of cut to prevent tool breakage. For example, a dynamometer can measure cutting forces to ensure they remain below 900 kg for a DMU 80 CNC milling machine.

Coolant Usage: Proper coolant application reduces heat and friction, extending tool life. Minimum quantity lubrication (MQL) minimizes coolant consumption while maintaining effectiveness. For titanium, use high-pressure coolant to improve chip evacuation.

Tool Reconditioning: Regrind and recoat tools when possible to extend their lifespan. Carbide tools can often be reground multiple times without significant performance loss.

Cost Analysis: Calculate the machine hourly rate, including tool and consumables costs, using tools like Spanflug MAKE. This ensures accurate budgeting and identifies cost-saving opportunities. For example, reducing machining time by 10% through optimized tool paths can lower overall consumables costs.

Practical Implementation and Best Practices

Implementing the above strategies requires a systematic approach:

Process Planning: Use CAM software to simulate tool paths and verify collision-free operations. Test initial parameters on a prototype to refine settings.

Machine Setup: Ensure rigid setups with minimal tool overhang to reduce vibration. For horizontal milling, place fixtures at the lowest point on the tombstone for stability.

Material-Specific Adjustments: Tailor parameters to the impeller material. For titanium, use lower cutting speeds and higher coolant pressure; for aluminum, increase speeds and reduce coolant.

Qualitätskontrolle: Inspect surface roughness and dimensional accuracy post-machining using tools like laser Doppler velocimetry (LDV) to verify performance against design specifications.

Schlussfolgerung

Optimizing the utilization rate of milling consumables for axial flow impellers involves a multi-faceted approach, integrating tool selection, machining strategies, parameter optimization, and consumables management. By choosing appropriate tools, employing efficient machining strategies, fine-tuning parameters, and monitoring wear, manufacturers can achieve high precision, reduce costs, and enhance productivity. This guide provides a professional, experience-based framework to ensure reliable and cost-effective impeller machining.