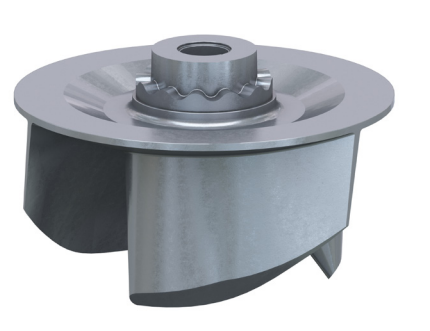

Impellers, critical components in pumps, turbines, and other fluid-handling systems, require surface treatments to enhance durability, corrosion resistance, and performance. Nickel plating and chrome plating are two widely used electroplating methods for impeller surface treatment. This technical analysis compares their properties, processes, applications, and key considerations, focusing on detailed parameters to guide engineers and manufacturers in selecting the optimal coating. The discussion emphasizes technical accuracy, systematic evaluation, and practical applicability without speculative trends or challenges.

Overview of Nickel Plating and Chrome Plating

Nickel plating and chrome plating are surface finishing techniques that deposit a metal layer onto a substrate to improve its mechanical and chemical properties. Both are applied to impellers to protect against wear, corrosion, and environmental degradation, but they differ in composition, application methods, and performance characteristics.

Vernickeln involves depositing a layer of nickel onto a substrate, typically via electrolytic or electroless processes. Electrolytic nickel plating uses an electric current to deposit nickel ions, while electroless nickel plating relies on a chemical reduction process, offering uniform coatings without external power. Nickel plating is valued for its corrosion resistance and versatility across substrates like steel, brass, and certain plastics.

Verchromen, or chromium plating, deposits a chromium layer through electroplating, where an electric current facilitates chromium ion deposition. Chrome plating is categorized into decorative (thin, aesthetic layers) and hard chrome (thicker, functional layers). For Laufräder, hard chrome is typically used due to its superior hardness and wear resistance.

Technical Properties and Parameters

The performance of nickel and chrome plating on impellers depends on specific technical properties, including hardness, corrosion resistance, wear resistance, thickness, and coefficient of friction. Below is a detailed comparison with precise parameters.

| Eigentum | Vernickeln | Verchromen |

|---|---|---|

| Härte | Electroless: 500–700 HV (as-plated), up to 1000 HV (heat-treated); Electrolytic: 150–400 HV | Hard Chrome: 800–1000 HV |

| Korrosionsbeständigkeit | Excellent, especially high-phosphorus electroless nickel (up to 1000 hours salt spray test) | Good, but susceptible to microcracks (500–800 hours salt spray test) |

| Abnutzungswiderstand | Good, improved with heat treatment or PTFE composites | Excellent, due to high hardness and low friction |

| Dicke der Beschichtung | 5–50 µm (electroless), 10–100 µm (electrolytic) | 25–100 µm (hard chrome), 0.05–0.5 µm (decorative) |

| Coefficient of Friction | 0.40 (electroless nickel), 0.20–0.30 (with PTFE) | 0.50 (hard chrome) |

Härte: Chrome plating offers superior hardness (800–1000 HV), making it ideal for impellers in abrasive environments. Electroless nickel can achieve comparable hardness (up to 1000 HV) after heat treatment, but electrolytic nickel is softer (150–400 HV).

Korrosionsbeständigkeit: Electroless nickel, particularly high-phosphorus variants (10–12% phosphorus), provides exceptional corrosion resistance, often exceeding 1000 hours in ASTM B117 salt spray tests. Chrome plating, while resistant to many chemicals (e.g., sodium chloride, nitric acid), is prone to microcracks, reducing its effectiveness in harsh corrosive environments.

Abnutzungswiderstand: Chrome’s high hardness ensures excellent wear resistance, suitable for impellers handling abrasive fluids. Nickel plating offers good wear resistance, which can be enhanced with heat treatment or composite coatings like nickel-PTFE for reduced friction.

Dicke der Beschichtung: Chrome plating for impellers typically ranges from 25–100 µm for hard chrome, providing robust protection. Electroless nickel coatings are thinner (5–50 µm), ideal for precise tolerances, while electrolytic nickel can be thicker (10–100 µm).

Coefficient of Friction: Nickel plating, especially with PTFE composites, achieves a lower coefficient of friction (0.20–0.30), reducing energy losses in impeller operation. Chrome plating has a higher coefficient (0.50), but its smoothness minimizes wear.

Application Processes

The plating process significantly affects the quality and performance of the coating on impellers. Both nickel and chrome plating involve multiple steps, but their methods differ in complexity and requirements.

Nickel Plating Process:

- Cleaning: The impeller surface is degreased and cleaned with alkaline or acid solutions to remove oils, dirt, and oxides.

- Activation: The substrate is immersed in an activation bath (e.g., acid etch) to enhance adhesion.

- Beschichtung: For electrolytic nickel, the impeller is submerged in a nickel sulfate or chloride bath with an electric current (current density: 2–10 A/dm²). For electroless nickel, a nickel-phosphorus bath with sodium hypophosphite is used, depositing at 0.5–1 µm/hour without current.

- Post-Treatment: Optional heat treatment (250–400°C) increases hardness, while rinsing ensures cleanliness.

Chrome Plating Process:

- Cleaning: Similar to nickel plating, involving degreasing and acid cleaning to remove contaminants.

- Activation: The impeller is etched in a chromic acid bath with reverse current to prepare the surface.

- Beschichtung: The impeller is immersed in a chromic acid bath with a lead/tin anode, using a current density of 15–30 A/dm². Deposition rate is approximately 25 µm/hour.

- Post-Treatment: Polishing or grinding may be required to achieve uniform thickness, followed by rinsing.

Key Differences: Electroless nickel plating offers uniform deposition, ideal for complex impeller geometries with vanes and recesses. Chrome plating requires precise control of current distribution, often needing conforming anodes for even coating, which increases complexity for intricate shapes.

Applications in Impeller Systems

Nickel and chrome plating are applied to impellers in various industries, including chemical processing, oil and gas, water treatment, and aerospace. The choice depends on the operating environment and performance requirements.

Nickel Plating Applications:

- Chemical Pumps: High-phosphorus electroless nickel withstands corrosive fluids like acids and alkalis.

- Water Treatment: Uniform coatings protect impellers in saline or chlorinated environments.

- Electronics Cooling Systems: Nickel-plated impellers ensure reliability in humid conditions.

Chrome Plating Applications:

- Oil and Gas Pumps: Hard chrome’s wear resistance suits impellers handling abrasive slurries.

- Aerospace Turbines: Chrome’s hardness and heat resistance protect high-speed impellers.

- Industrial Pumps: Chrome plating extends impeller life in high-wear applications.

Comparative Suitability: Nickel plating excels in corrosive environments with complex geometries, while chrome plating is preferred for high-wear, abrasive conditions requiring maximum hardness.

Cost and Maintenance Considerations

Cost and maintenance are critical factors in selecting a plating method for impellers, influencing long-term operational efficiency.

Kosten: Chrome plating is generally more expensive due to higher material costs, complex process requirements (e.g., conforming anodes), and environmental compliance for hexavalent chromium. Nickel plating, particularly electroless, is cost-effective for uniform coatings but may incur additional costs for heat treatment or composite additives. Typical costs vary by impeller size and coating thickness, with chrome plating ranging from $100–$1000 per component and nickel plating from $50–$500.

Maintenance: Chrome-plated impellers require periodic polishing to maintain smoothness, especially in abrasive environments. Nickel-plated impellers, particularly electroless, need minimal maintenance due to their uniform, self-lubricating properties. Cleaning nickel surfaces with mild soap or vinegar solutions removes stains, while chrome may need specialized polishes to prevent tarnishing.

Environmental and Safety Considerations

Both plating processes involve chemicals with environmental and safety implications, requiring careful handling and compliance with regulations.

Vernickeln: Electroless nickel baths use hypophosphite, which produces less toxic waste than chrome plating. However, nickel salts can cause allergic reactions, and effluent treatment is necessary to prevent environmental pollution. Electrolytic nickel generates more waste due to higher chemical consumption.

Verchromen: Hexavalent chromium (Cr6+), used in traditional chrome plating, is a carcinogen, necessitating strict disposal regulations (e.g., EPA guidelines). Fume suppressants reduce airborne emissions but add to waste complexity. Trivalent chromium (Cr3+) is a safer alternative but less common for hard chrome applications.

Implications for Impellers: Manufacturers must invest in waste management systems, increasing costs for chrome plating. Nickel plating’s lower environmental impact may be preferable for sustainable operations.

Practical Considerations for Impeller Plating

Several practical factors influence the choice between nickel and chrome plating for impellers, including substrate compatibility, geometry, and operational conditions.

Substrate Compatibility: Both coatings are compatible with common impeller materials like steel, stainless steel, and copper alloys. Electroless nickel is uniquely suited for aluminum and certain plastics, expanding its applicability.

Geometrie: Impellers with complex vanes and recesses benefit from electroless nickel’s uniform deposition, reducing post-processing. Chrome plating may require additional polishing for evenness, increasing labor.

Operational Conditions: For impellers in corrosive fluids (e.g., seawater), electroless nickel is superior. In abrasive conditions (e.g., slurries), chrome’s hardness is advantageous.

Beschränkungen: Chrome plating’s microcrack susceptibility can lead to corrosion in crevices, a concern for impellers with enge Toleranzen. Nickel plating’s softer as-plated hardness may limit its use in high-wear applications without heat treatment.

Schlussfolgerung

Nickel plating and chrome plating offer distinct advantages for impeller surface treatment, with the choice depending on specific performance requirements. Electroless nickel plating excels in corrosion resistance and uniform coating, ideal for complex geometries and corrosive environments. Hard chrome plating provides unmatched hardness and wear resistance, suitable for abrasive conditions. By evaluating technical parameters, application processes, costs, and environmental factors, manufacturers can select the optimal plating method to enhance impeller durability and efficiency. This systematic comparison provides a clear framework for decision-making, ensuring reliable performance in demanding applications.