Impellers are critical components in industrial systems such as pumps, turbines, and compressors, where they facilitate fluid movement and energy transfer. Ensuring their quality during procurement is vital to guarantee performance, durability, and compliance with technical specifications. Inspection reports serve as documented evidence that impellers meet stringent quality and regulatory standards. This guide details the key inspection reports required for impeller procurement, providing technical parameters, compliance requirements, and a systematic approach to quality assurance. Aimed at procurement professionals and engineers, this content emphasizes technical accuracy and clarity, avoiding artistic embellishments.

Importance of Inspection Reports in Impeller Procurement

Inspection reports are essential to validate the quality and performance of impellers, which operate under demanding conditions such as high pressure, corrosive environments, or extreme temperatures. These reports confirm that the impeller meets design specifications, material standards, and operational requirements. Failure to verify these aspects can result in system inefficiencies, premature wear, or catastrophic failures, leading to costly downtime or safety risks. The procurement process relies on these reports to ensure supplier accountability and compliance with industry standards like ISO, ASTM, or API. By integrating comprehensive inspection reports, buyers can mitigate risks and ensure reliable performance in applications ranging from chemical processing to aerospace.

Key Inspection Reports for Impeller Procurement

The following inspection reports are critical for impeller procurement, each addressing specific quality and performance aspects. These reports are typically provided by suppliers or third-party inspection agencies and must align with technical and regulatory requirements.

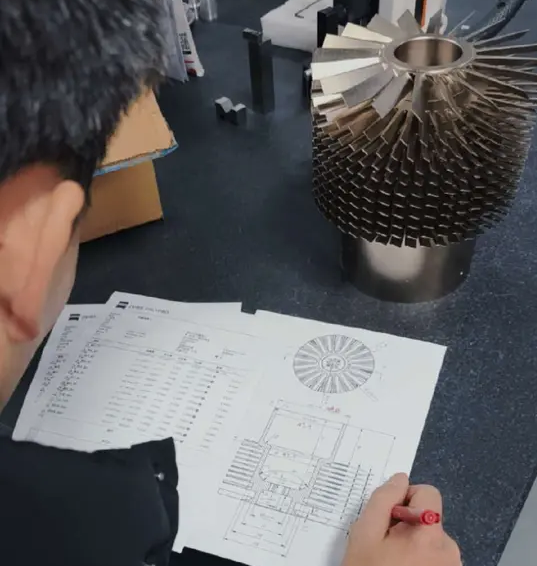

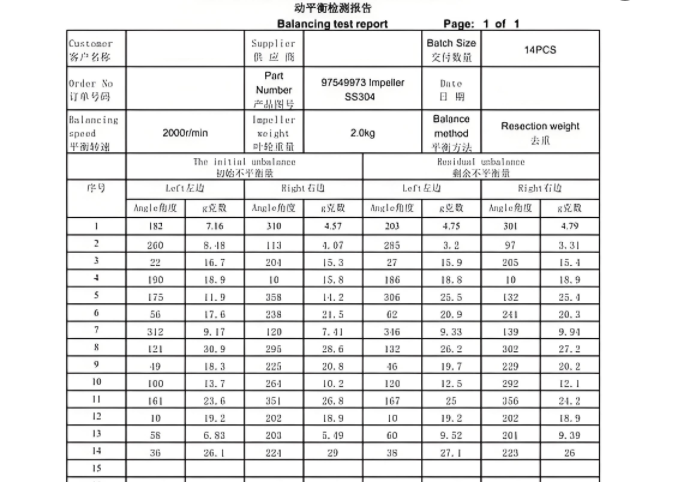

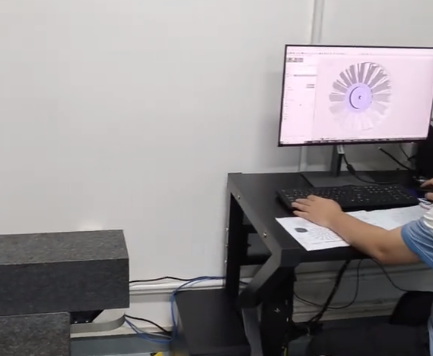

Dynamic Balancing Report

The Dynamic Balancing Report verifies that the impeller is balanced to minimize vibration and ensure smooth operation at high rotational speeds. Imbalance can lead to excessive wear, noise, or mechanical failure in systems like centrifugal pumps or turbines.

Technische Parameter:

- Balance Quality Grade: Tested per ISO 1940-1, typically G2.5 for high-speed impellers (e.g., 10,000 RPM).

- Residual Unbalance: Measured in gram-millimeters (g·mm), e.g., ≤4 g·mm for a 5 kg impeller at G2.5.

- Testing Equipment: Dynamic balancing machines with sensitivity to 0.01 g·mm.

- Rotationsgeschwindigkeit: Tested at operational speeds (e.g., 1,500-15,000 RPM) to simulate real-world conditions.

Purpose: Ensures minimal vibration and stress on bearings and shafts, extending system lifespan. For example, an unbalanced impeller in a high-speed pump can cause bearing failure within months.

Prozess: Dynamic balancing involves mounting the impeller on a balancing machine, rotating it at specified speeds, and measuring unbalance. Corrections are made by adding or removing material (e.g., welding weights or grinding) to achieve the required balance grade.

Material Certification Report

The Material Certification Report verifies the composition and properties of the materials used in impeller manufacturing. Impellers are often constructed from materials like stainless steel (e.g., 304 or 316), titanium, or high-strength alloys, depending on the application. This report ensures that the material meets specified standards and is suitable for the operating environment.

Technische Parameter:

- Chemical Composition: Analyzed via spectrometry to confirm element percentages, e.g., 16-18% chromium and 10-14% nickel for 316 stainless steel.

- Mechanical Properties: Tensile strength (e.g., ≥515 MPa for 316 stainless steel), yield strength (e.g., ≥205 MPa), and elongation (e.g., ≥40%).

- Hardness: Measured in Brinell (e.g., ≤217 HB) or Rockwell scales, per ASTM E18.

- Standards: Compliance with ASTM A743, ISO 683/13, or customer-specific requirements.

Purpose: Ensures the material can withstand operational stresses, corrosion, and wear. For example, in chemical pumps, improper material composition could lead to corrosion failure in acidic environments.

Dimensional Inspection Report

The Dimensional Inspection Report confirms that the impeller’s physical dimensions conform to design specifications. Precision is critical to ensure proper fit, balance, and performance within the system.

Technische Parameter:

- Key Dimensions: Blade thickness (e.g., ±0.05 mm tolerance), outer diameter (e.g., 250 ± 0.1 mm), and hub bore diameter.

- Measurement Tools: Coordinate Measuring Machine (CMM) for 0.01 mm accuracy, laser scanners, or precision calipers.

- Geometric Tolerances: Adherence to GD&T standards (ASME Y14.5), including concentricity (e.g., ≤0.02 mm) and parallelism.

Purpose: Verifies that the impeller fits seamlessly into the assembly, preventing issues like misalignment or excessive vibration, especially in high-speed applications.

Non-Destructive Testing (NDT) Report

Non-Destructive Testing (NDT) Reports identify defects such as cracks, voids, or inclusions without damaging the impeller. Common NDT methods include ultrasonic testing (UT), radiographic testing (RT), magnetic particle testing (MT), and dye penetrant testing (PT).

Technische Parameter:

| NDT Method | Application | Defect Detection | Standards |

|---|---|---|---|

| Ultrasonic Testing (UT) | Internal voids, inclusions | ≥0.5 mm flaw size | ASTM E114, ISO 16810 |

| Radiographic Testing (RT) | Internal cracks, porosity | 2% material thickness sensitivity | ASTM E94, EN 12681 |

| Magnetic Particle Testing (MT) | Surface cracks (ferromagnetic materials) | ≥0.1 mm crack length | ASTM E709 |

| Dye Penetrant Testing (PT) | Surface cracks, porosity | ≥0.05 mm crack width | ASTM E165 |

Purpose: Ensures structural integrity by detecting defects that could lead to failure under operational stress, such as in high-pressure pump systems.

Performance Testing Report

The Performance Testing Report evaluates the impeller’s functionality under simulated operating conditions, including flow rate, head, efficiency, and balance.

Technische Parameter:

- Hydraulic Performance: Flow rate (e.g., 600 m³/h), head (e.g., 60 m), and efficiency (e.g., ≥80% at design point).

- Rotational Balance: Tested per ISO 1940-1, achieving balance quality grade G2.5 for high-speed impellers.

- Vibration Analysis: Maximum vibration velocity (e.g., ≤4.5 mm/s RMS) per ISO 10816.

Purpose: Confirms that the impeller meets performance expectations, ensuring energy efficiency and operational stability in systems like centrifugal pumps.

Surface Finish and Heat Treatment Report

This report verifies the impeller’s surface finish and heat treatment processes, which impact durability, corrosion resistance, and fluid dynamics.

Technische Parameter:

- Surface Roughness: Measured as Ra (e.g., ≤0.8 µm for polished surfaces) using profilometers, per ASME B46.1.

- Wärmebehandlung: Processes like annealing or quenching, with hardness values (e.g., 200-250 HB for stainless steel), per ASTM A370.

- Coating (if applicable): Thickness (e.g., 50-100 µm for corrosion-resistant coatings) and adhesion testing.

Purpose: Ensures optimal surface quality for reduced friction and enhanced durability, critical for impellers in abrasive or corrosive environments.

Industry Standards and Compliance

Impellers must adhere to international and industry-specific standards to ensure reliability and regulatory compliance. The following table summarizes key standards relevant to impeller procurement.

| Standard | Organization | Application |

|---|---|---|

| ISO 1940-1 | International Organization for Standardization | Balance quality for rotating machinery |

| ASTM A743 | American Society for Testing and Materials | Castings for corrosion-resistant applications |

| API 610 | American Petroleum Institute | Centrifugal pumps for petroleum and chemical industries |

| EN 10204 | European Standards | Inspection documents for metallic products |

Compliance with these standards ensures that inspection reports are universally accepted and that the impeller meets operational and safety requirements.

Integrating Inspection Reports into the Procurement Process

A systematic approach to integrating inspection reports into procurement enhances efficiency and reduces risks. The following steps outline the process:

- Specify Requirements: Define material, dimensional, and performance criteria in the procurement contract.

- Supplier Qualification: Select suppliers with certified quality management systems (e.g., ISO 9001).

- Pre-Production Checks: Verify raw material certifications and manufacturing processes before production.

- In-Process Inspections: Conduct NDT and dimensional checks during manufacturing to catch defects early.

- Final Validation: Perform performance testing and review all reports before accepting delivery.

- Documentation Audit: Ensure reports are complete, accurate, and compliant with standards.

This structured process ensures that only high-quality impellers are procured, minimizing operational risks.

Common Challenges and Solutions

Procurement professionals may encounter challenges such as incomplete documentation, varying supplier standards, or delays in testing. Solutions include:

- Standardized Templates: Provide suppliers with clear report formats to ensure consistency.

- Third-Party Verification: Engage independent agencies like Bureau Veritas or Lloyd’s Register for unbiased inspections.

- Supplier Audits: Conduct regular audits to verify supplier compliance with quality standards.

These measures address pain points by improving reliability and streamlining the inspection process.

Schlussfolgerung

Procuring impellers requires rigorous quality assurance through comprehensive inspection reports, including Material Certification, Dimensional Inspection, Non-Destructive Testing, Performance Testing, and Surface Finish/Heat Treatment Reports. These documents validate the impeller’s compliance with technical specifications and industry standards, ensuring reliability and performance. By integrating these reports into a structured procurement process and addressing common challenges, buyers can secure high-quality impellers that meet operational demands. This guide provides a clear, technical framework for procurement professionals to navigate the complexities of impeller quality assurance effectively.