Titanium alloys are widely used in aerospace, medical, and automotive industries due to their high strength-to-weight ratio, corrosion resistance, and durability. However, their low thermal conductivity and high chemical reactivity pose significant machining challenges. This guide provides detailed best practices for machining titanium alloys, focusing on machine tools, cutting tools, workpiece preparation, programming strategies, and cooling methods to achieve precision, efficiency, and tool longevity.

Machine Tool Requirements: Power and Rigidity

Rigidity and sufficient power are critical for machining titanium alloys due to their high cutting resistance. The choice of machine tool specifications depends on whether the process involves high-volume production or single/small-batch machining.

Großserienproduktion

For high-volume production, machine tools must handle significant cutting forces and maintain thermal stability. Key requirements include:

- Main Spindle Power: ≥30 kW to manage high cutting resistance, reduce spindle temperature rise, extend spindle life, and minimize accuracy drift.

- Spindle Speed Range: 2000–8000 rpm, with stable high torque at low speeds to ensure consistent performance during heavy cutting.

- High-Pressure Internal Cooling System: ≥70 bar to effectively remove chip heat, prolong tool life, and maintain machining precision.

Single/Small-Batch Machining

For single or small-batch production, lower-power machines (10–15 kW) can be used with adjusted strategies to achieve quality results:

- Adopt a low depth-of-cut and multiple-pass strategy to reduce cutting forces.

- Avoid prolonged continuous cutting to prevent excessive machine temperature rise and thermal deformation.

Cutting Tools: Sharpness and Heat Resistance

Selecting the right cutting tools is essential for machining titanium alloys, as their properties demand sharpness and heat resistance to prevent tool wear and ensure surface quality.

Roughing Tools

Roughing tools must withstand high cutting forces and heat. Recommended specifications include:

- Material: Tungsten-cobalt carbide or micro-grain carbide for durability.

- Geometry:

- Large positive rake angle to reduce cutting forces.

- Rounded or reinforced cutting edges to prevent chipping.

- Coating: TiAlN or AlTiN for excellent high-temperature stability.

- Tool Types: Bull-nose end mills, insert mills, or roughing round inserts for efficient material removal.

Finishing Tools

Finishing tools focus on achieving high surface quality and precision:

- Material: Ultra-fine grain carbide for enhanced toughness.

- Coating: Multi-layer TiAlN + DLC or nACo for superior wear resistance and low friction.

- Tool Design: Tools with micro-radius edges to prevent corner chipping.

Schnittparameter

Optimal cutting parameters balance efficiency and tool life. The following table provides recommended parameters for machining titanium alloys:

| Parameter | Aufrauen | Fertigstellung |

|---|---|---|

| Cutting Speed (Vc) | 50–100 m/min | 50–100 m/min |

| Feed per Tooth (fz) | 0.05–0.15 mm/tooth | 0.05–0.10 mm/tooth |

| Axial Depth of Cut (ap) | 0.5–2 mm (can increase for roughing) | 0.2–0.5 mm |

| Radial Depth of Cut (ae) | ≤30% of tool diameter | ≤10% of tool diameter |

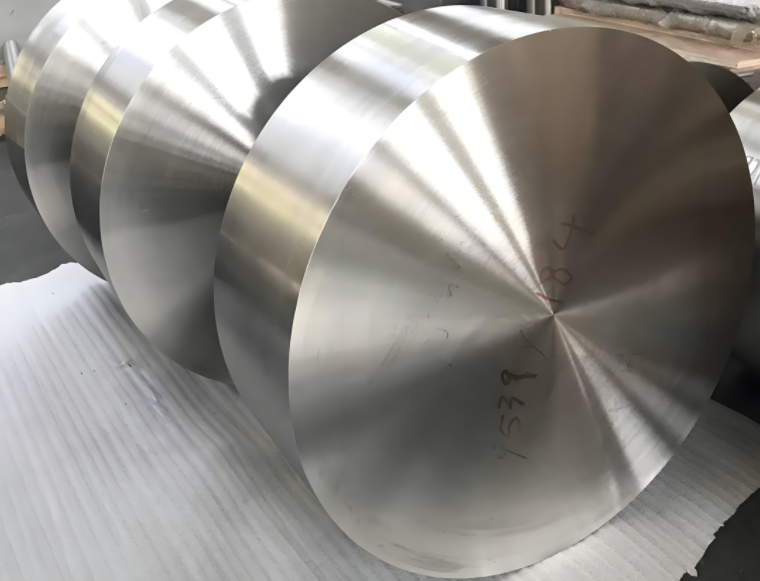

Workpiece Preparation: Heat Treatment and Stability

Proper workpiece preparation enhances material stability and machinability, reducing tool wear and improving surface quality.

Pre-Machining Heat Treatment

Heat treatment improves the microstructure of titanium alloys:

- Solution Treatment + Aging: Performed in sequence to enhance material stability and reduce sensitivity to cutting heat, extending tool life.

- Preferred Material State: α+β phase for balanced strength and machinability. Avoid fully annealed states, as they are too soft and prone to tool sticking.

Clamping and Fixturing

Effective clamping minimizes vibration and thermal effects:

- Use high-rigidity fixtures to prevent resonance.

- Employ soft jaws, preload rings, and thermal insulation layers to reduce heat transfer and maintain precision.

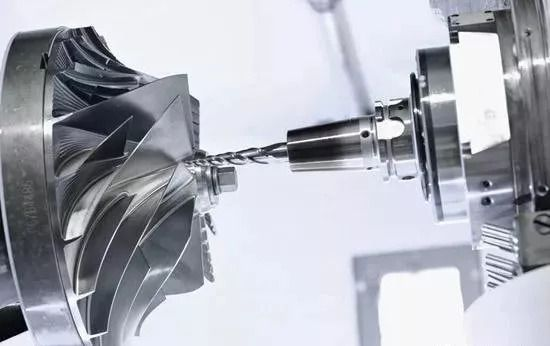

Programming and Toolpath Strategies: Dynamic Milling

Efficient programming and toolpath strategies are critical for minimizing heat buildup and maintaining consistent cutting loads.

Recommended CAM Software

Software such as Mastercam, PowerMill, and UG NX supports dynamic milling (High Efficiency Milling), which optimizes material removal rates while reducing tool wear.

Toolpath Strategies

Dynamic milling strategies ensure stable cutting conditions:

- Constant Cutting Load: Maintains consistent tool engagement to reduce heat accumulation.

- Spiral or Ramped Entry: Avoids sharp impacts by entering the material gradually.

- Minimized Full-Width Cutting: Uses transitional arcs at corners to reduce stress.

- Continuous Feed: Keeps the tool engaged without interruption to avoid work hardening.

Cooling and Lubrication: Managing Heat

Effective cooling and lubrication are essential to mitigate the low thermal conductivity of titanium alloys and prevent thermal damage.

Recommended Cooling Methods

Optimal cooling strategies include:

- High-Pressure Internal Cooling (≥70 bar): Combined with emulsion or oil mist for efficient chip evacuation and heat dissipation.

- Minimum Quantity Lubrication (MQL) + Internal Cooling: Reduces thermal shock while maintaining lubrication.

- Avoid Dry Cutting: Prevents thermal cracking and uneven cooling.

Additional Best Practices for Titanium Alloy Machining

The following table summarizes key considerations for optimizing the machining process and ensuring safety:

| Aspekt | Best Practice |

|---|---|

| Cutting Process | Control entry angle, minimize intermittent cutting, and avoid impacts. |

| Werkzeugverschleiß | Inspect tools every 15–30 minutes and replace as needed. |

| Surface Hardening | Use small feed rates and multiple finishing passes to remove hardened layers. |

| Workpiece Cleaning | Regularly remove chips to prevent secondary cutting by titanium debris. |

| Safety and Fire Prevention | Keep the environment dry and free of oil. Equip the workspace with fire sand or CO2 extinguishers, as titanium chips are flammable. |

Schlussfolgerung

Bearbeitung Titanlegierungen requires careful consideration of machine tool capabilities, cutting tool selection, workpiece preparation, programming strategies, and cooling methods. By adhering to the guidelines outlined above, manufacturers can achieve high precision, extend tool life, and ensure safety. Implementing high-rigidity machines, heat-resistant tools, dynamic milling strategies, and effective cooling systems will optimize performance and address the unique challenges of titanium alloy machining.