Precision impeller machining is a critical process in industries such as aerospace, automotive, and energy, where impellers must meet stringent performance and durability requirements. This guide provides a detailed examination of the costs, techniques, and parameters involved in machining impellers, offering practical insights for manufacturers aiming to achieve high accuracy and efficiency. Drawing on established methods and technical expertise, the content is structured to address key aspects of the process systematically.

Overview of Precision Impeller Machining

Impellers are rotating components used in pumps, turbines, and compressors to transfer energy to fluids. Their complex geometries, including curved blades and narrow flow passages, demand advanced machining techniques to achieve tight tolerances and smooth surface finishes. Precision machining typically involves computer numerical control (CNC) systems, which ensure repeatability and accuracy. The primary methods include 5-axis CNC milling, turning, and electrical discharge machining (EDM), each suited to specific impeller designs and materials.

Key considerations in impeller machining include material selection, dimensional accuracy, surface quality, and production volume. Common materials include aluminum alloys, stainless steel, and titanium, each presenting unique machining requirements. The process is divided into roughing, semi-finishing, and finishing stages, with each stage requiring specific tools, parameters, and strategies to optimize results.

Cost Factors in Impeller Machining

The cost of precision impeller machining depends on several factors, including material, complexity, equipment, labor, and production volume. Below is a breakdown of the primary cost components, supported by typical ranges and considerations.

| Cost Component | Beschreibung | Typical Cost Range |

|---|---|---|

| Material | Cost of raw materials like aluminum, stainless steel, or titanium. | $5–$50 per kg, depending on material grade. |

| Machine Setup | Programming, fixturing, and tool calibration for CNC machines. | $100–$500 per setup for small batches. |

| Bearbeitungszeit | Hourly rate for CNC machine operation, including roughing and finishing. | $20–$100 per hour, based on machine type and complexity. |

| Werkzeugbau | Cost of cutting tools, including milling cutters and EDM electrodes. | $50–$500 per tool, with lifespan affecting total cost. |

| Labor | Skilled machinists and engineers for setup, operation, and inspection. | $30–$80 per hour, depending on expertise. |

Material costs vary significantly, with Titan being more expensive than aluminum due to its hardness and machining difficulty. Setup costs are higher for low-volume production, as fixed expenses are spread across fewer units. Machining time is influenced by the impeller’s complexity, with intricate designs requiring longer cycles. Tooling costs depend on tool wear, which is higher for harder materials like titanium. Labor costs reflect the need for skilled operators to manage advanced CNC systems and ensure quality.

For example, machining a 15-inch aluminum impeller for a pump may cost $500–$1,500 per unit for a batch of 10, including material, setup, and machining time. In contrast, a titanium impeller of similar size may cost $2,000–$4,000 due to higher material and tooling expenses. High-volume production reduces per-unit costs by distributing setup and programming expenses across more parts.

Machining Techniques for Impellers

Several techniques are employed in precision impeller machining, each tailored to specific requirements. The following methods are commonly used, with detailed parameters to guide implementation.

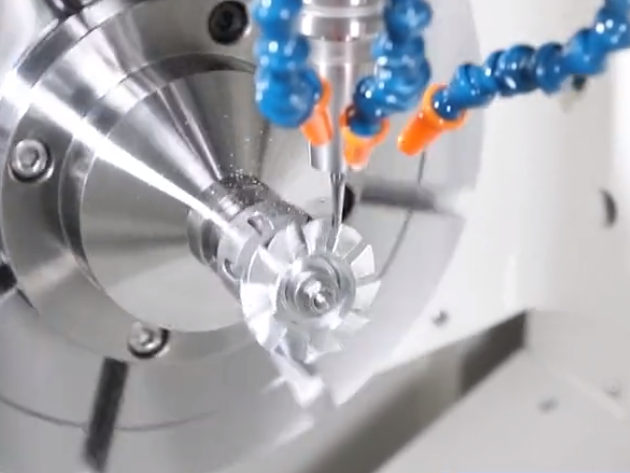

5-Axis CNC Milling

5-axis CNC milling is the preferred method for machining complex impellers due to its ability to access all surfaces in a single setup. The additional A-axis (tilting table) and C-axis (table rotation) allow the cutting tool to approach the workpiece from multiple angles, reducing setup time and improving accuracy.

- Spindeldrehzahl: 8,000–20,000 RPM, depending on material (e.g., 12,000 RPM for aluminum, 8,000 RPM for titanium).

- Vorschubgeschwindigkeit: 100–500 mm/min for roughing, 50–200 mm/min for finishing.

- Schnitttiefe: 0.5–2 mm for roughing, 0.1–0.5 mm for finishing.

- Werkzeug-Typ: Carbide end mills with 4–6 flutes, diameter 6–12 mm.

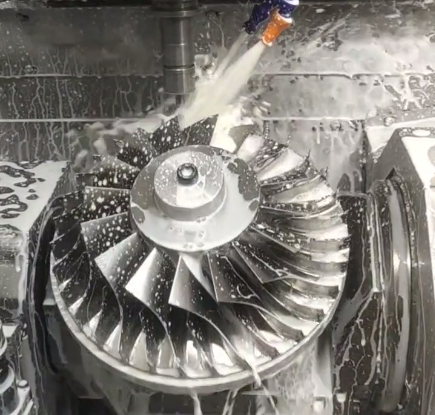

- Coolant: High-pressure coolant (20–50 bar) to reduce heat and improve chip evacuation.

5-axis milling is ideal for impellers with deep, narrow flow passages and twisted blades, as it minimizes tool deflection and ensures consistent surface finishes. For example, a centrifugal impeller with a 0.02 mm tolerance may require a finishing pass at 100 mm/min with a 0.2 mm depth of cut to achieve a surface roughness of Ra 0.8 µm.

CNC-Drehen

CNC turning is used for machining the hub and outer diameter of impellers. The workpiece rotates while a stationary cutting tool removes material, making it suitable for cylindrical features.

- Spindeldrehzahl: 1,000–3,000 RPM, adjusted for material hardness.

- Vorschubgeschwindigkeit: 0.1–0.3 mm/rev for roughing, 0.05–0.1 mm/rev for finishing.

- Schnitttiefe: 1–3 mm for roughing, 0.1–0.5 mm for finishing.

- Werkzeug-Typ: Carbide inserts with positive rake angles for aluminum, negative rake for titanium.

Turning is cost-effective for simpler impeller designs but less suitable for complex blade geometries, which require milling. A typical turning operation for an impeller hub may achieve a tolerance of ±0.01 mm with a surface finish of Ra 1.6 µm.

Elektrische Funkenerosion (EDM)

EDM is used for impellers made from hard materials or those requiring intricate features that are difficult to machine conventionally. It involves creating an electrical arc between an electrode and the workpiece to remove material.

- Voltage: 50–200 V, depending on material conductivity.

- Current: 5–50 A for roughing, 1–10 A for finishing.

- Pulse Duration: 10–100 µs for roughing, 1–10 µs for finishing.

- Electrode Material: Copper or graphite, shaped to match the desired geometry.

EDM is slower than milling but excels in machining titanium or nickel-based alloys with tolerances as low as ±0.005 mm. It is often used for finishing critical features like blade edges.

Key Parameters for Optimal Machining

Achieving high-quality impellers requires careful control of machining parameters. The following table summarizes critical parameters for 5-axis milling, the most common method for impeller machining.

| Parameter | Aufrauen | Semi-Finishing | Fertigstellung |

|---|---|---|---|

| Spindle Speed (RPM) | 8,000–12,000 | 10,000–15,000 | 12,000–20,000 |

| Feed Rate (mm/min) | 200–500 | 100–300 | 50–200 |

| Schnitttiefe (mm) | 1-2 | 0.5–1 | 0.1–0.5 |

| Surface Roughness (Ra, µm) | 3.2–6.3 | 1.6–3.2 | 0.4–0.8 |

These parameters vary based on material and impeller design. For aluminum, higher spindle speeds and feed rates are feasible, while titanium requires lower values to minimize tool wear. Surface roughness targets are critical, as smoother finishes improve fluid dynamics and reduce wear in operation. For instance, a finishing pass at 15,000 RPM and 100 mm/min can achieve Ra 0.4 µm on stainless steel, meeting aerospace standards.

Tool path planning is equally important. Strategies like flank milling, where the tool’s side contacts the workpiece, reduce machining time for blade surfaces. Point milling, used for finishing, ensures precise contours but is slower. CAD/CAM software, such as AutoCAD or SolidWorks, is used to generate tool paths, with G&M codes dictating tool movements. Simulation in CAM software helps optimize paths, reducing errors and cycle times.

Practical Considerations for Manufacturers

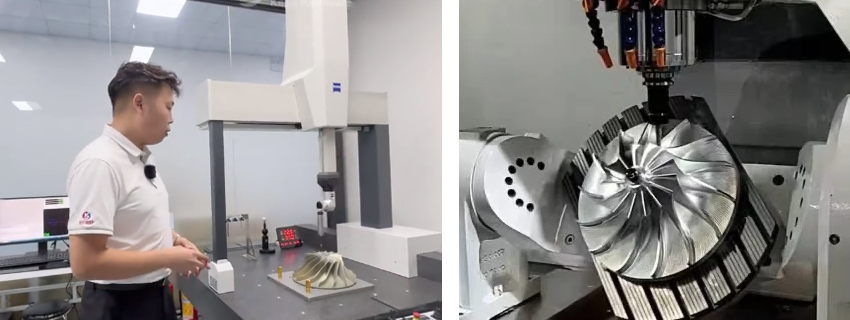

Manufacturers must address several practical aspects to ensure successful impeller machining. Material selection is critical, as it affects machinability, cost, and performance. Aluminum is easier to machine but less durable than titanium, which is preferred for high-stress applications. Workholding solutions, such as custom fixtures or hydraulic clamps, ensure stability during 5-axis milling, preventing vibration and misalignment.

Quality control is essential to meet tolerances and performance standards. Techniques like on-machine measuring and coordinate measuring machines (CMMs) verify dimensions, with tolerances often as tight as ±0.01 mm. Balancing tests ensure impellers operate smoothly, minimizing vibration. Compliance with standards like ISO 9001 and ASTM ensures reliability and safety.

Tool wear is a significant consideration, particularly for hard materials. Regular tool inspection and replacement prevent defects and maintain accuracy. Coolant management, using high-pressure systems, extends tool life and improves chip evacuation, especially in deep flow passages. Finally, operator expertise is crucial, as skilled machinists optimize parameters and troubleshoot issues effectively.

Schlussfolgerung

Precision impeller machining is a complex but essential process that demands advanced techniques, careful parameter control, and strategic cost management. By leveraging 5-axis CNC milling, turning, and EDM, manufacturers can achieve the tight tolerances and high-quality finishes required for impellers in demanding applications. Understanding cost factors, optimizing machining parameters, and addressing practical considerations ensure efficient production and reliable outcomes. This guide provides a comprehensive framework for manufacturers seeking to excel in impeller machining, grounded in technical expertise and practical experience.