Stainless steel, an iron-based alloy renowned for its corrosion resistance and versatility, has transformed industries since its discovery. This article provides a detailed examination of its history, key characteristics, types, and wide-ranging applications, supported by technical data and structured insights.

History of Stainless Steel

The development of stainless steel marked a significant milestone in metallurgy, driven by the need for corrosion-resistant materials. Its history spans over a century, with key discoveries in the early 20th century.

In the late 19th century, scientists noted the corrosion-resistant properties of chromium-alloyed steels. However, stainless steel as we know it emerged in the early 1900s. In 1912, German metallurgists Eduard Maurer and Benno Strauss at Krupp Iron Works patented austenitic stainless steel, known today as AISI Type 304, containing 18% chromium and 8% nickel. Around the same time, Harry Brearley, an English metallurgist, discovered a martensitic stainless steel alloy in 1913 while seeking erosion-resistant materials for gun barrels. His alloy, with 12.8% chromium and 0.24% carbon, was termed "rustless steel" and laid the foundation for modern stainless steel applications. Brearley’s work led to the commercialization of stainless steel for cutlery in Sheffield, England.

Concurrent developments occurred in the United States, where Elwood Haynes patented a similar alloy in 1919, leading to the formation of the American Stainless Steel Corporation. By the 1920s, stainless steel saw rapid adoption in industries, with innovations like the 18/8 composition (Type 304) becoming standard. The 1930s introduced duplex stainless steels, and subsequent decades saw advancements in high-nitrogen and precipitation-hardening grades, expanding its utility.

Characteristics of Stainless Steel

Stainless steel’s defining feature is its corrosion resistance, attributed to a minimum chromium content of 10.5%. This section explores its chemical composition, mechanical properties, and environmental resilience.

Chemical Composition

Stainless steel is primarily an iron-based alloy with chromium as the key element, forming a passive chromium oxide layer that protects against corrosion. Additional alloying elements enhance specific properties:

- Chrom (Cr): Minimum 10.5%, provides corrosion resistance.

- Nickel (Ni): Enhances ductility and corrosion resistance, especially in austenitic grades (e.g., 8–10.5% in Type 304).

- Molybdän (Mo): Improves resistance to pitting and chloride environments (e.g., 2–3% in Type 316).

- Kohlenstoff (C): Influences hardness and strength, typically 0.03–0.8%.

- Nitrogen (N): Increases strength and corrosion resistance in high-nitrogen grades.

The exact composition varies by grade, tailored to specific applications.

Mechanische Eigenschaften

Stainless steel exhibits a range of mechanical properties, depending on its microstructure. The table below summarizes key properties for common grades:

| Grade | Type | Zugfestigkeit (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| Type 304 | Austenitic | 515-690 | 205 | 40 | 201 |

| Type 316 | Austenitic | 515-690 | 205 | 40 | 217 |

| Type 410 | Martensitic | 440–660 | 290 | 20 | 223 |

| 2205 (Duplex) | Duplex | 620–880 | 450 | 25 | 293 |

Austenitic grades offer high ductility and formability, while martensitic grades provide superior hardness. Duplex grades balance strength and corrosion resistance.

Korrosionsbeständigkeit

The passive chromium oxide layer self-heals in the presence of oxygen, making stainless steel resistant to rust. However, corrosion resistance varies by environment:

- Phosphoric and Nitric Acids: Most grades resist attack at room temperature.

- Sulfuric Acid: Type 304 is limited to 3% acid at room temperature, while Type 316 resists up to 20% at 50°C.

- Hydrochloric Acid: Damages all stainless steels, requiring specialized alloys like Type 904L.

- Pitting and Crevice Corrosion: Molybdenum-enhanced grades (e.g., Type 316) excel in chloride-rich environments like seawater.

Issues like intergranular corrosion (from high-temperature welding) and galvanic corrosion (from contact with dissimilar metals) can occur but are mitigated through proper grade selection and maintenance.

Other Properties

Stainless steel is non-magnetic in austenitic grades, magnetic in ferritic and martensitic grades, and has lower electrical conductivity than copper. It resists high and low temperatures, with some grades maintaining strength at 980–1,050°C during austenitizing. Its hygienic, non-porous surface makes it ideal for food and medical applications.

Types of Stainless Steel

Stainless steel is classified into four main categories based on microstructure, each with distinct properties and applications:

| Type | Composition | Eigenschaften | Anwendungen |

|---|---|---|---|

| Austenitic | 17–20% Cr, 8–14% Ni, low C | Non-magnetic, high ductility, corrosion-resistant | Kitchen equipment, chemical tanks, architectural panels |

| Ferritic | 10.5–27% Cr, low Ni | Magnetic, good ductility, thermal fatigue resistance | Automotive exhausts, appliances, heat exchangers |

| Martensitic | 12–16% Cr, 0.1–1% C | High hardness, magnetic, moderate corrosion resistance | Cutlery, turbine blades, surgical instruments |

| Duplex | 19–32% Cr, up to 5% Mo, low Ni | High strength, excellent corrosion resistance | Oil and gas pipelines, seawater applications |

Anwendungen von rostfreiem Stahl

Stainless steel’s versatility makes it indispensable across industries. Its applications leverage its corrosion resistance, strength, and aesthetic appeal.

Industrial Applications

Stainless steel is critical in harsh environments:

- Chemical and Petrochemical: Type 316 and duplex grades are used in tanks and pipelines for storing acids and corrosive chemicals.

- Öl und Gas: Duplex stainless steels (e.g., 2205) are employed in offshore platforms and pipelines due to their resistance to chloride stress corrosion.

- Water Treatment: Stainless steel resists corrosion in high-chloride environments, used in desalination plants and wastewater systems.

Medical and Pharmaceutical

Type 316 and 420 grades are used for surgical instruments and implants due to their biocompatibility and ease of sterilization. High-nitrogen stainless steels are explored for advanced applications like magnetic drug targeting and radiopaque stents.

Food and Beverage

Type 304 is the standard for food processing equipment, brewery tanks, and kitchen appliances due to its hygienic surface and resistance to food acids like vinegar.

Construction and Architecture

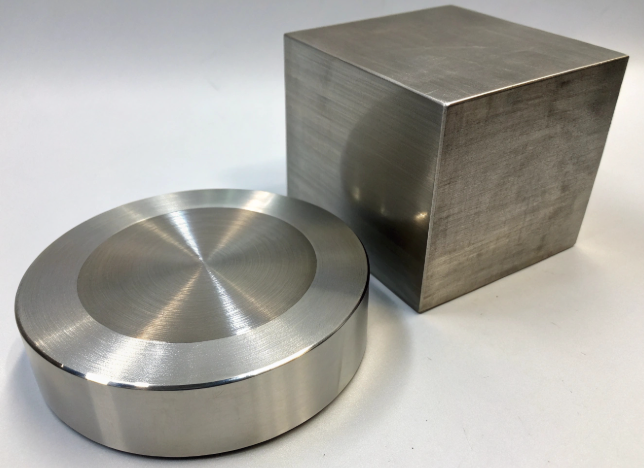

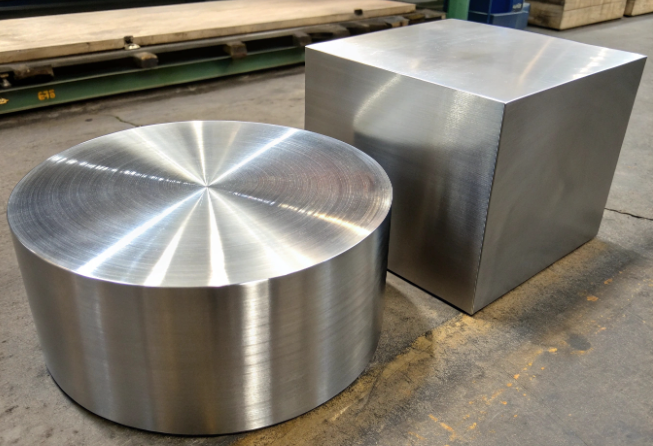

Stainless steel is used in structural components, cladding, and decorative elements (e.g., pipe or impeller). Its durability and low maintenance make it ideal for bridges and marine structures.

Automotive and Aerospace

Ferritic grades are used in exhaust systems, while austenitic grades appear in structural components. High-strength grades support lightweight, durable parts in aircraft.

Sustainability and Recycling

Stainless steel is 100% recyclable without degradation, with approximately 85% of stainless steel being recycled globally. Its long service life reduces environmental impact, aligning with sustainable practices.

Schlussfolgerung

Stainless steel’s evolution from an accidental discovery to a cornerstone of modern industry underscores its importance. Its corrosion resistance, mechanical versatility, and recyclability make it a material of choice across diverse sectors. By understanding its history, characteristics, and applications, industries can optimize its use for innovative and sustainable solutions.