Computer Numerical Control (CNC) machining requires rigorous inspection to ensure parts meet dimensional, surface, and material quality standards. Inspection equipment verifies geometric accuracy, surface finish, material properties, and dynamic performance, including tools like spectrometers for material analysis and dynamic balancing machines for rotational stability. This guide details key CNC inspection tools, their technical parameters, and applications in quality control.

Categories of CNC Inspection Equipment

CNC inspection equipment is categorized by function: geometric accuracy, surface quality, material properties, and dynamic performance. Below is a comprehensive overview of these categories, including spectrometers and dynamic balancing machines.

Geometric Accuracy Inspection Equipment

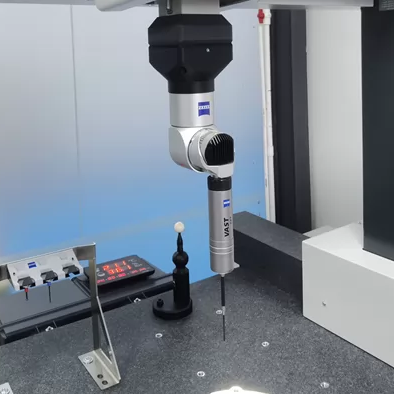

These tools measure dimensional and positional tolerances to ensure parts align with design specifications.

| Ausrüstung | Purpose | Key Parameters | Anwendungen |

|---|---|---|---|

| Koordinatenmessmaschine (CMM) | Measures 3D geometry (length, diameter, positional tolerances) | Accuracy: ±0.001 mm; Range: Up to 2 m x 1.5 m x 1 m | Aerospace, automotive components |

| Laser Interferometer | Evaluates machine positioning and linearity | Resolution: 0.01 µm; Range: Up to 30 m | Machine calibration |

| Roundness Tester | Assesses roundness, cylindricity, coaxiality | Accuracy: ±0.02 µm; Max diameter: 300 mm | Shafts, bearings |

Surface Quality Inspection Equipment

Surface quality affects part performance and longevity. These tools evaluate roughness and defects.

- Surface Roughness Tester: Measures Ra (0.01–10 µm) and Rz; measurement speed up to 1 mm/s.

- White Light Interferometer: Provides 3D surface topography; vertical resolution 0.1 nm.

- Optical Microscope: Magnification up to 1000x for detecting scratches or tool marks.

Material Properties Inspection Equipment

Material analysis ensures compliance with design specifications, particularly for alloys and metals. Spectrometers are critical for verifying elemental composition.

| Ausrüstung | Purpose | Key Parameters | Anwendungen |

|---|---|---|---|

| Optical Emission Spectrometer (OES) | Analyzes elemental composition of metals/alloys | Detection limit: 1 ppm; Elements: C, S, Fe, Al, etc. | Raw material verification, quality control |

| X-Ray Fluorescence (XRF) Spectrometer | Non-destructive elemental analysis | Detection range: Na to U; Accuracy: ±0.1%; Analysis time: 10 s | Alloy analysis, coatings |

| Hardness Tester | Measures material hardness | Range: 20–70 HRC; Accuracy: ±0.5 HRC | Heat-treated parts, tool steel |

Spectrometers ensure material quality in CNC machining. Optical Emission Spectrometers (OES) offer high sensitivity for trace elements (1–10 ppm, e.g., sulfur), ideal for verifying alloy composition (e.g., 316 stainless steel: 16–18% Cr, 10–14% Ni). X-Ray Fluorescence (XRF) spectrometers enable non-destructive testing, suitable for coatings and finished parts. Applications include:

- Raw Material Verification: Ensures incoming materials match specifications.

- Post-Processing Analysis: Detects contamination or compositional changes from heat treatment or welding.

- Failure Analysis: Identifies material anomalies in defective parts, such as incorrect carbon content.

Dynamic Performance and Online Inspection

Dynamic and real-time inspection ensures machine stability and part quality during production, with dynamic balancing machines playing a key role for rotational components.

- Dynamic Balancing Machine: Measures and corrects imbalance in rotating parts (e.g., spindles, rotors); unbalance detection sensitivity: 0.1 g·mm/kg; speed range: 100–10,000 RPM; suitable for high-speed CNC spindles and tool holders to reduce vibration and wear.

- Vibration Analyzer: Detects spindle vibrations; frequency range: 10 Hz–10 kHz; sensitivity: 0.1 m/s².

- In-Process Probe Systems: Contact or non-contact systems; accuracy: ±0.002 mm.

- Vision Systems: CCD-based; resolution up to 5 MP for automated defect detection.

How To Select CNC Inspection Equipment

Equipment selection depends on part complexity, material type, and production volume. Key considerations include:

- Accuracy Requirements: Sub-micron needs demand CMMs or laser interferometers.

- Material Typ: Spectrometers for alloy verification; hardness testers for steels.

- Dynamic Performance: Dynamic balancing machines for rotating components; vibration analyzers for machine stability.

- Production Scale: Vision systems and probes for high-volume automation.

Für high-precision parts, combining CMMs with spectrometers ensures dimensional and material accuracy. For rotating components, dynamic balancing machines are critical to minimize vibration. Automated lines benefit from in-process probes and vision systems for efficiency.

Schlussfolgerung

CNC inspection equipment, from CMMs to spectrometers and dynamic balancing machines, ensures precision, quality, and reliability in manufacturing. By selecting tools based on specific needs, manufacturers can meet stringent tolerances, material standards, and performance requirements, enhancing product performance.