Dynamic balancing is a fundamental process in mechanical engineering that ensures rotating objects, such as rotors, wheels, or fan blades, operate smoothly by minimizing vibration, noise, and mechanical wear. This article provides a comprehensive overview of dynamic balancing, including its definition, practical applications, and precision grades, drawing from industry standards and technical insights.

Definition of Dynamic Balancing

Dynamic balancing refers to the process of adjusting the mass distribution of a rotating object so that its center of mass aligns with its rotational axis. This alignment eliminates unbalanced forces and moments that cause vibration, noise, and premature wear during rotation. Unlike static balancing, which addresses imbalance in a stationary state, dynamic balancing accounts for forces and moments generated at high rotational speeds.

Unbalanced rotating components can lead to excessive vibration, reduced equipment lifespan, and compromised safety. For example, an unbalanced car tire can cause wheel shake, uneven tire wear, and steering instability. Dynamic balancing mitigates these issues by ensuring uniform mass distribution.

Importance of Dynamic Balancing

Dynamic balancing is critical for the performance and longevity of rotating machinery. Key benefits include:

- Reduced Vibration: Minimizes mechanical stress and prevents component failure.

- Lower Noise Levels: Enhances operational comfort, especially in automotive and industrial settings.

- Extended Equipment Life: Reduces wear on bearings, shafts, and other components.

- Improved Efficiency: Ensures smoother operation, reducing energy losses.

- Enhanced Safety: Prevents catastrophic failures in high-speed machinery.

Statistics indicate that approximately 70% of rotating machinery vibration issues stem from imbalance, underscoring the importance of dynamic balancing in industries like automotive, aerospace, and manufacturing.

Applications of Dynamic Balancing

Dynamic balancing is employed across various industries to ensure the smooth operation of rotating components. Common applications include:

- Autoindustrie: Balancing car tires to prevent wheel shake and ensure driving comfort. New tires are balanced at the factory, but rebalancing is often required after wear or repair.

- Industrial Machinery: Balancing rotors in engines, turbines, and pumps to reduce vibration and extend service life.

- Luft- und Raumfahrt: Balancing turbine blades and propellers to ensure precision and safety in aircraft.

- Manufacturing: Balancing spindles in machine tools, such as grinders, to achieve high-precision machining.

- Energy Sector: Balancing wind turbine rotors and generator components to optimize performance.

In the automotive sector, for instance, an imbalance exceeding 50 grams in a tire can significantly reduce bearing life and cause uneven wear, highlighting the need for precise balancing.

How Dynamic Balancing Works

The dynamic balancing process involves detecting and correcting mass imbalances in a rotating object. The key steps are:

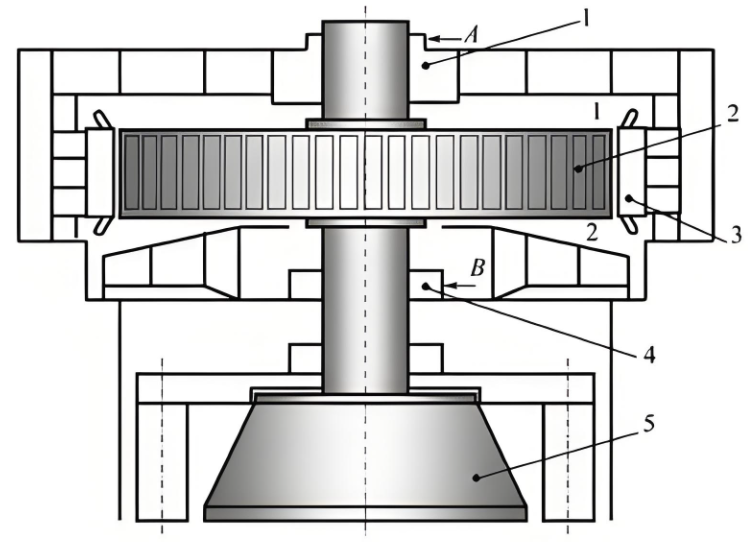

- Detection: A dynamic balancing machine measures the magnitude and location of imbalance by analyzing vibrations or forces during rotation.

- Correction: Imbalance is corrected by adding counterweights (e.g., balance weights on tires), removing material (e.g., drilling), or adjusting component positions.

- Verification: The balanced component is retested to ensure vibrations are within acceptable limits.

Advanced techniques, such as on-site dynamic balancing, allow corrections without disassembling machinery, improving efficiency and precision.

Dynamic Balancing Precision Grades

The International Organization for Standardization (ISO) defines precision grades for dynamic balancing under the ISO 1940-1 standard. These grades, expressed in units of g.mm/kg (grams of unbalance per kilogram of rotor mass), specify the allowable residual unbalance for different types of rotating machinery.

| Balance Quality Grade | g.mm/kg | Example Applications |

|---|---|---|

| G0.4 | 0.4 | Precision grinding spindles, gyroscopes, high-precision impellers |

| G1 | 1 | Recording equipment, precision grinders, precise impellers |

| G2.5 | 2.5 | Gas turbines, aircraft components, fans, impellers |

| G6.3 | 6.3 | Turbochargers, general machinery |

| G16 | 16 | Agricultural machinery, engine components |

| G40 | 40 | Car wheels, engine drive components |

| G100 | 100 | Multi-cylinder diesel engines |

| G250 | 250 | Crankshaft drives of high-speed four-cylinder diesel engines for marine use |

| G630 | 630 | Crankshaft drives of large four-stroke marine diesel engines; crankshaft drives of elastically mounted marine diesel engines |

| G1600 | 1600 | Components of marine diesel engines of type I and type II, such as rigidly mounted marine diesel engines |

| G4000 | 4000 | Rigid crankshaft drives of large, low-speed marine diesel engines with specific installation conditions |

The table above, derived from ISO 1940-1, illustrates the balance quality grades and their corresponding applications. Lower grades (e.g., G0.4) indicate higher precision, suitable for sensitive equipment, while higher grades (e.g., G100) are acceptable for less critical applications.

Types of Dynamic Balancing

Dynamic balancing can be categorized into two main types based on the rotor's behavior:

- Rigid Rotor Balancing: Applied to rotors operating below their critical speed, using soft or hard-bearing balancing machines.

- Flexible Rotor Balancing: Used for rotors operating above critical speed, employing methods like modal balancing or influence coefficient techniques.

Each type requires specific equipment and expertise to achieve the desired balance quality.

Difficulty in Dynamic Balancing

Despite its benefits, dynamic balancing faces difficulties, including:

- High-Speed Balancing Costs: Specialized equipment for high-speed rotors can be expensive.

- Precision Loss: Transport or assembly may introduce new imbalances.

- Complex Rotors: Large or thermally deformable rotors require advanced techniques.

Ongoing advancements in on-site balancing technology and automated balancing systems are addressing these challenges, improving efficiency and accuracy.

Schlussfolgerung

Dynamic balancing is an essential process for ensuring the smooth and efficient operation of rotating machinery. By aligning the mass distribution of rotating components, it minimizes vibration, noise, and wear, enhancing performance and safety across industries. The ISO 1940-1 precision grades provide a standardized framework for achieving optimal balance, tailored to specific applications. Understanding and implementing dynamic balancing is crucial for professionals in mechanical engineering, automotive, and related fields.