Impeller surface treatment is critical in industries where fluid machinery operates under demanding conditions. Surface treatments enhance impeller durability, efficiency, and resistance to wear, corrosion, and cavitation. This article examines industries with high requirements for impeller surface treatment, detailing specific parameters and technical considerations. The focus is on wastewater treatment, chemical processing, oil and gas, aerospace, engine manufacturing, and semiconductors, where impeller performance directly impacts operational reliability and cost.

Wastewater Treatment

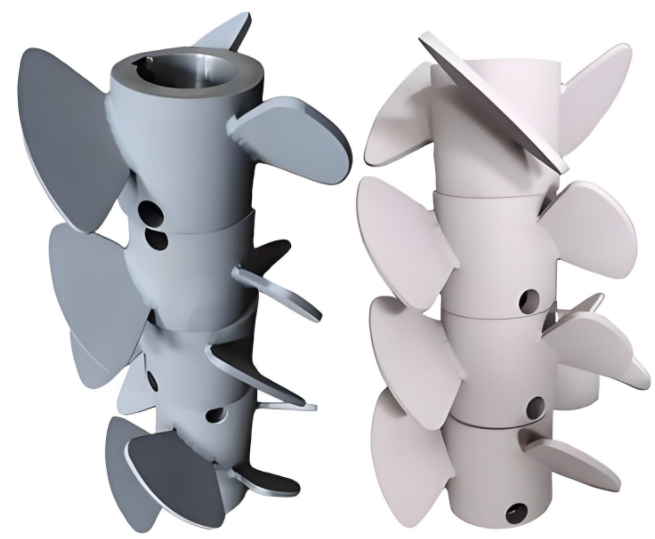

Wastewater treatment facilities rely on centrifugal pumps and mixers to handle fluids containing solids, abrasive particles, and corrosive chemicals. Impellers in these systems face significant wear due to the presence of sand, grit, and organic matter. Surface treatments are essential to extend impeller lifespan and maintain pump efficiency.

Key surface treatments include cold tar epoxy coatings for large turbine agitators, which protect carbon steel impellers from rust and extend service life. These coatings, applied to impeller blades and shafts, are typically 5-10 mils thick and suitable for mildly corrosive environments but less effective in highly abrasive conditions. Electropolishing and passivation are also used to smooth surfaces and remove free iron, reducing the risk of bacterial growth and improving cleanability.

Specific parameters for impeller surface treatment in wastewater treatment include:

| Parameter | Value | Purpose |

|---|---|---|

| Surface Roughness (Ra) | 0.8-1.6 µm | Reduces adhesion of solids and biofilm formation |

| Dicke der Beschichtung | 5-10 mils (cold tar epoxy) | Protects against rust and mild corrosion |

| Material Härte | 40-60 Durometer A (elastomeric coatings) | Balances erosion and corrosion resistance |

These parameters ensure impellers can handle solids-laden fluids without clogging, as seen in vortex impellers designed for wastewater applications. The choice of treatment depends on the fluid’s solids content, pH (typically 6-9), and temperature (up to 70°C for dry bearing designs).

Chemical Processing

Chemical processing involves handling aggressive fluids, such as acids, alkalis, and solvents, which necessitate robust impeller surface treatments. Stainless steel impellers, particularly 316 and 316L grades, are common due to their resistance to chloride ions. Duplex stainless steel is used in high-pressure or stress-corrosion environments, offering superior strength and corrosion resistance.

Surface treatments like Kynar (PVDF) coatings provide chemical resistance and durability for impellers in chemical reactors. These coatings, applied at 5-10 mils, are suitable for handling corrosive fluids in processes like emulsification and polymerization. Electropolishing achieves a surface roughness of 0.4-0.8 µm, reducing friction and improving hydraulic efficiency.

Parameters for chemical processing impellers include:

- Surface Roughness (Ra): 0.4-0.8 µm to minimize friction losses and enhance flow efficiency.

- Coating Type: Kynar or PFA (Teflon-based) for chemical resistance, applied at 5-10 mils thickness.

- Material Composition: 316L stainless steel with 16-18% chromium and 2-3% molybdenum for corrosion resistance.

- Operating Temperature: Up to 120°C for coated impellers, ensuring compatibility with process conditions.

These treatments address the need for impellers to withstand continuous exposure to corrosive media while maintaining precise flow control in stirred tank reactors.

Öl und Gas

The oil and gas industry uses centrifugal pumps for crude oil transport, slurry handling, and petroleum extraction. Impellers face erosion-corrosion from abrasive particles and high-pressure conditions. Duplex stainless steel impellers with balanced austenite/ferrite ratios (50:50) are preferred for their resistance to corrosive wear, particularly in zinc hydrometallurgy processes where nitrogen content is controlled at 0.1-0.3% to optimize material properties.

Surface coatings, such as hardfacing with tungsten carbide or elastomeric linings (3/8-inch thick), are applied to reduce wear from solid particles. Computational fluid dynamics (CFD) studies show that surface roughness impacts pump efficiency, with rougher surfaces (Ra > 3.2 µm) reducing head and efficiency by up to 4.75% and 0.75 kW input power, respectively.

Key parameters include:

- Surface Roughness (Ra): 0.8-1.6 µm to balance efficiency and durability.

- Coating Hardness: 40-60 Durometer A for elastomeric linings to absorb particle impact energy.

- Pressure Distribution: Uniform pressure gradient from leading to trailing edge to minimize cavitation at the suction side.

- Fluid Solids Content: Up to 50% by volume, requiring robust coatings to prevent erosion.

These treatments ensure impellers maintain performance under high-pressure conditions (up to 100 bar) and abrasive environments, reducing maintenance frequency.

Luft- und Raumfahrt

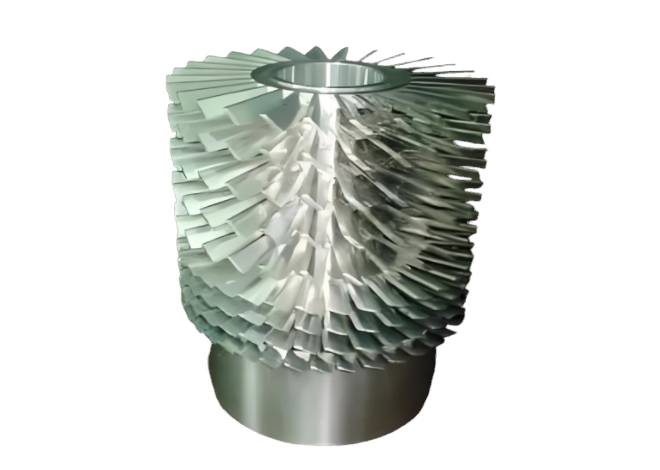

In aerospace, impellers are used in fuel pumps, hydraulic systems, and cooling systems for aircraft and spacecraft. These components operate under extreme conditions, including high temperatures, high pressures, and exposure to specialized fluids like jet fuel or hydraulic oils. Surface treatments are critical to ensure reliability, reduce wear, and meet stringent safety and performance standards.

Titan and nickel-based alloy impellers are common due to their high strength-to-weight ratio and corrosion resistance. Surface treatments include plasma-sprayed ceramic coatings, such as yttria-stabilized zirconia (YSZ), applied at 10-15 mils to provide thermal and wear resistance. Electropolishing is used to achieve a surface roughness of 0.2-0.4 µm, minimizing friction and improving fuel efficiency in high-speed pumps.

Parameters for aerospace impellers include:

| Parameter | Value | Purpose |

|---|---|---|

| Surface Roughness (Ra) | 0.2-0.4 µm | Minimizes friction and enhances fuel efficiency |

| Dicke der Beschichtung | 10-15 mils (YSZ ceramic) | Provides thermal and wear resistance |

| Betriebstemperatur | Up to 400°C | Ensures compatibility with high-temperature fluids |

These treatments address the need for impellers to operate reliably in extreme environments, such as high-altitude or space conditions, where failure can compromise mission safety.

Engine Manufacturing

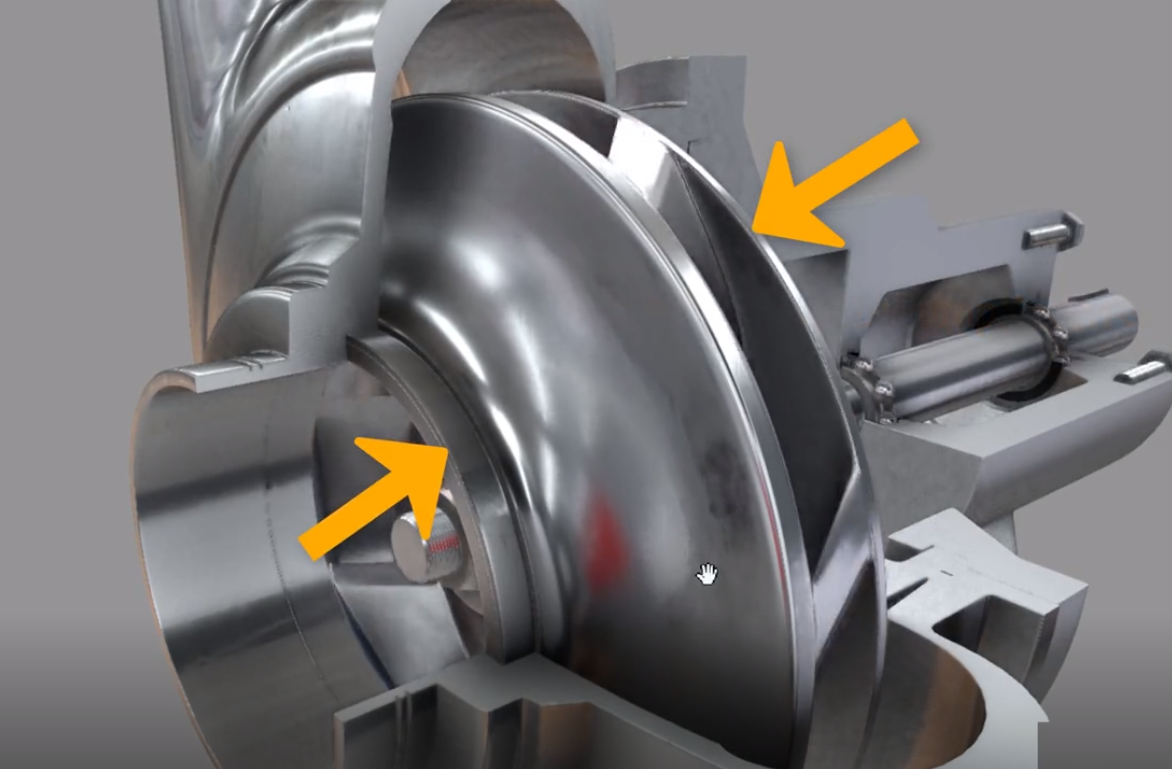

Engine manufacturing, particularly for automotive and marine engines, relies on impellers in fuel pumps, water pumps, and turbochargers. These impellers face high rotational speeds (up to 100,000 rpm in turbochargers) and exposure to fuels, coolants, and exhaust gases. Surface treatments enhance wear resistance, reduce cavitation, and ensure consistent performance.

Impellers are typically made from Aluminiumlegierungen or stainless steel, with surface treatments like anodizing (for aluminum) or chromium carbide coatings (for steel) applied at 5-10 mils to improve hardness and corrosion resistance. Polishing to a surface roughness of 0.4-0.8 µm reduces drag and improves flow efficiency in high-speed applications.

Parameters for engine manufacturing impellers include:

- Surface Roughness (Ra): 0.4-0.8 µm to reduce drag and improve flow efficiency.

- Coating Thickness: 5-10 mils (chromium carbide or anodizing) for wear and corrosion resistance.

- Material Hardness: 60-70 HRC for coated surfaces to withstand high-speed wear.

- Operating Speed: Up to 100,000 rpm for turbocharger impellers, requiring precise surface finishes.

These treatments ensure impellers maintain performance under high mechanical stress and thermal cycling, critical for engine reliability.

Semiconductors

The semiconductor industry uses impellers in vacuum pumps and chemical delivery systems for wafer fabrication. These impellers handle ultrapure water, corrosive etchants, and gases in cleanroom environments, requiring high cleanliness and chemical resistance. Surface treatments must prevent contamination and ensure compatibility with stringent purity standards.

Impellers are often made from 316L stainless steel or fluoropolymers like PTFE. Surface treatments include electropolishing to achieve a surface roughness of 0.2-0.4 µm and PFA coatings (5 mils) for chemical inertness. These treatments minimize particle generation and ensure compliance with SEMI standards for cleanroom equipment.

Parameters for semiconductor impellers include:

- Surface Roughness (Ra): 0.2-0.4 µm to prevent particle adhesion and ensure cleanroom compatibility.

- Coating Thickness: 5 mils (PFA) for chemical resistance in etching processes.

- Material Purity: 99.9% for 316L stainless steel to minimize contamination risks.

- Operating Pressure: Vacuum conditions (down to 10^-6 Torr) for vacuum pump impellers.

These treatments address the need for contamination-free operation and durability in corrosive chemical environments, critical for semiconductor manufacturing.

Technical Considerations for Impeller Surface Treatment

Surface treatment selection depends on several factors, including fluid properties, operating conditions, and material compatibility. Below are key considerations across the discussed industries:

- Fluid Properties: Chemical composition, pH, solids content, and viscosity dictate coating type and thickness. For example, acidic fluids in chemical processing require Kynar coatings, while ultrapure water in semiconductors needs PFA coatings.

- Operating Conditions: Temperature (up to 400°C in aerospace), pressure (up to 100 bar in oil and gas, or 10^-6 Torr in semiconductors), and impeller speed (up to 100,000 rpm in engines) influence treatment durability.

- Material Compatibility: Materials like titanium, 316L stainless steel, or fluoropolymers must be compatible with fluids to prevent degradation.

- Efficiency Impact: Surface roughness affects hydraulic efficiency, with smoother surfaces (Ra < 0.8 µm) reducing friction losses by up to 4.75% in centrifugal pumps.

- Regulatory Compliance: In semiconductors, treatments must meet SEMI standards for cleanliness, while aerospace requires compliance with FAA or NASA specifications.

These considerations ensure that surface treatments are tailored to specific industry needs, optimizing impeller performance and longevity.

Schlussfolgerung

Impeller surface treatment is a critical factor in industries like wastewater treatment, chemical processing, oil and gas, aerospace, engine manufacturing, and semiconductors. Each industry has unique requirements driven by fluid properties, operating conditions, and performance demands. Surface treatments, such as coatings, electropolishing, and passivation, are tailored to address corrosion, wear, and efficiency challenges. Specific parameters, including surface roughness, coating thickness, and material hardness, are carefully selected to ensure durability and reliability. By understanding these requirements and applying appropriate treatments, industries can enhance equipment lifespan, reduce maintenance costs, and maintain operational efficiency.