Machining titanium alloy impellers is a critical process in industries such as aerospace, automotive, and energy, where these components are valued for their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme conditions. However, tool breakage is a prevalent issue during the machining of titanium alloy impellers, particularly due to the unique properties of titanium alloys and the complex geometry of impellers. This article examines the primary reasons for tool breakage, focusing on material characteristics, machining conditions, tool selection, and process parameters, providing a technical and systematic understanding of the issue.

Material Properties of Titanium Alloys

Titanium alloys, such as Ti-6Al-4V (Grade 5), are widely used for impellers due to their excellent mechanical properties. However, these same properties contribute significantly to tool breakage during machining. The following factors are critical:

- Low Thermal Conductivity: Titanium alloys have poor thermal conductivity, approximately 37% lower than Inconel 718 and 86% lower than AISI 1045 steel. During machining, heat generated at the cutting zone remains concentrated near the tool-workpiece interface, elevating tool temperatures. This can lead to thermal softening of the tool material, accelerated wear, and eventual breakage.

- High Strength and Hardness: Titanium alloys exhibit high tensile strength (e.g., Ti-6Al-4V has a tensile strength of 990 N/mm²) and hardness (330–380 Vickers). These properties require high cutting forces, which increase mechanical stress on the tool, leading to chipping or fracture.

- Chemical Reactivity: Titanium is highly reactive at elevated temperatures, forming micro-welds with the tool material. This phenomenon, known as adhesion, creates a built-up edge (BUE) on the tool, increasing cutting resistance and promoting tool failure.

- Low Modulus of Elasticity: With a Young’s modulus roughly half that of steel, titanium alloys are prone to elastic deformation during machining. This leads to springback and chatter, causing vibrations that stress the tool and contribute to breakage.

- Work Hardening Tendency: Titanium alloys harden rapidly during machining, especially if cutting parameters are not optimized. The hardened layer increases the material’s abrasiveness, accelerating tool wear and increasing the likelihood of breakage.

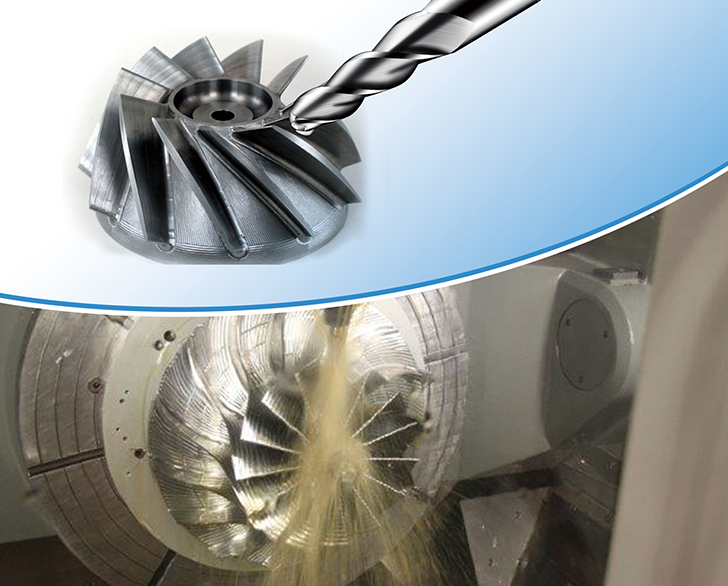

Complex Geometry of Impellers

Laufräder, particularly integral designs, have complex geometries with curved surfaces, thin blades, and narrow grooves, which exacerbate machining difficulties and contribute to tool breakage. Key aspects include:

- Thin-Walled Structures: Impeller blades often have wall thicknesses as low as 5 mm, making them prone to deformation under cutting forces. This deformation causes unstable tool-workpiece contact, increasing vibration and tool stress. For example, machining a titanium alloy impeller with a blade thickness of 5 mm and length of 70 mm requires precise control to maintain dimensional accuracy (IT6 tolerance) and surface roughness (Ra 1.6).

- Curved Surfaces and Narrow Grooves: The intricate shapes of impellers require multi-axis CNC machining, often with four- or five-axis machines. These complex tool paths increase the risk of tool deflection, particularly in deep grooves where the tool engages with limited clearance, leading to higher cutting forces and potential breakage.

- Variable Cutting Forces: The uneven chip formation in titanium alloy impellers, caused by curling and irregular chip fracture, results in fluctuating cutting forces. These fluctuations induce tool vibration, which can lead to fatigue failure or chipping of the cutting edge.

Inappropriate Cutting Conditions

Suboptimal machining parameters are a major contributor to tool breakage when machining titanium alloy impellers. The following conditions are critical:

- Excessive Cutting Speeds: High cutting speeds generate excessive heat due to titanium’s low thermal conductivity. For example, increasing cutting speed from 150 m/min to 250 m/min can increase cutting forces due to strain hardening, leading to tool wear and breakage. A recommended cutting speed for Ti-6Al-4V is typically 30–60 m/min to minimize heat generation.

- Inadequate Feed Rates: Low feed rates cause excessive rubbing rather than cutting, increasing heat and work hardening. A larger chip load, such as 0.1–0.15 mm/tooth, is recommended to reduce rubbing and promote chip evacuation.

- Improper Depth of Cut: Excessive axial or radial depth of cut increases cutting forces, leading to tool deflection and breakage. For titanium alloys, a radial engagement of 30% of the tool radius is often advised to balance material removal and tool life.

- Insufficient Coolant Application: Titanium machining requires high-pressure coolant (e.g., 70–100 bar) to dissipate heat and flush chips. Inadequate coolant flow allows heat to accumulate, causing thermal damage to the tool. A 10% concentrated coolant solution is commonly used to enhance cooling efficiency.

| Parameter | Recommended Value | Anmerkungen |

|---|---|---|

| Cutting Speed (Vc) | 30-60 m/min | Lower speeds reduce heat generation and tool wear. |

| Feed Rate (f) | 0.1–0.15 mm/tooth | Higher feed rates minimize rubbing and work hardening. |

| Radial Engagement (ae) | 30% of tool radius | Reduces cutting forces and tool deflection. |

| Coolant Pressure | 70-100 bar | High-pressure coolant improves chip evacuation and cooling. |

Tool Material and Design Limitations

The choice of cutting tool material and design significantly impacts tool life when machining titanium alloy impellers. Common issues include:

- Inadequate Tool Material: Tools made from materials like high-speed steel (HSS) are unsuitable for titanium due to their inability to withstand high temperatures and cutting forces. Solid carbide tools or those with polycrystalline diamond (PCD) or cubic boron nitride (CBN) inserts are preferred for their high wear resistance and thermal stability.

- Improper Tool Geometry: Tools with insufficient rake angles or weak cutting edges are prone to chipping. Positive rake angle geometries reduce cutting forces and heat generation. For example, a tool with a 10–15° rake angle is effective for titanium machining.

- Tool Coating Issues: Uncoated tools or those with inappropriate coatings suffer from rapid wear due to titanium’s chemical reactivity. Coatings like titanium aluminum nitride (TiAlN) or aluminum titanium nitride (AlTiN) form an oxide layer at high temperatures, reducing adhesion and wear. For instance, AlTiN-coated carbide tools can extend tool life by up to 30% compared to uncoated tools.

- Tool Wear Mechanisms: Common wear mechanisms include adhesive wear, abrasive wear, and cratering. Adhesive wear occurs when titanium adheres to the tool, forming a BUE that increases cutting resistance. Abrasive wear is caused by the hardened workpiece surface, while cratering results from high temperatures and chemical reactions at the tool’s rake face.

Chip Formation and Evacuation Issues

Chip formation and evacuation play a significant role in tool breakage during titanium alloy impeller machining. Key issues include:

- Long and Stringy Chips: Titanium alloys produce long, continuous chips due to their gummy nature. These chips can wrap around the tool or workpiece, causing tool damage or surface defects. Using tools with chip-breaking geometries or higher feed rates (e.g., 0.1–0.15 mm/tooth) promotes shorter, thicker chips that are easier to evacuate.

- Poor Chip Evacuation: In deep grooves or narrow impeller channels, chips can accumulate, increasing cutting resistance and heat. High-pressure coolant systems (70–100 bar) are essential to flush chips from the cutting zone, reducing the risk of tool breakage.

- Chip Adhesion: Titanium’s stickiness causes chips to adhere to the tool, forming a BUE that disrupts cutting and increases tool stress. Proper coolant application and coated tools (e.g., TiAlN) minimize chip adhesion.

Machine Tool and Setup Rigidity

The rigidity of the machining setup is critical for preventing tool breakage when machining titanium alloy impellers. Key considerations include:

- Machine Tool Rigidity: Titanium machining requires rigid machine tools with high torque and low spindle speeds (e.g., 500–1000 RPM for a 12 mm end mill). Less rigid machines are prone to vibration, leading to tool deflection and breakage.

- Tool Holder Stability: Loose or misaligned tool holders cause vibration, increasing stress on the tool. High-precision tool holders, such as hydraulic or shrink-fit holders, ensure stability and reduce runout.

- Workpiece Fixturing: Insecure workpiece fixturing leads to chatter, especially for thin-walled impellers. Rigid clamping systems and vibration-damping fixtures are necessary to maintain stability during machining.

| Tool Material/Coating | Vorteile | Anwendungen |

|---|---|---|

| Solid Carbide with TiAlN | High wear resistance, reduced adhesion | Milling, drilling, roughing |

| PCD Inserts | Superior hardness, extended tool life | Finishing, high-precision cuts |

| CBN Inserts | High thermal stability, abrasion resistance | Turning, hard machining |

Strategies to Mitigate Tool Breakage

To reduce tool breakage when machining titanium alloy impellers, the following strategies are recommended:

- Optimize Cutting Parameters: Use low cutting speeds (30–60 m/min), higher feed rates (0.1–0.15 mm/tooth), and moderate depths of cut (30% radial engagement) to minimize heat and wear.

- Enhance Cooling Systems: Implement high-pressure coolant systems (70–100 bar) with 10% concentrated coolant to dissipate heat and improve chip evacuation.

- Select Appropriate Tools: Use solid carbide tools with TiAlN or AlTiN coatings and positive rake angle geometries to reduce cutting forces and adhesion.

- Ensure Machine Rigidity: Employ rigid CNC machines with high torque and stable tool holders to minimize vibration and deflection.

- Monitor Tool Wear: Regularly inspect tools for signs of wear (e.g., chipping, cratering) and replace them promptly to prevent catastrophic failure.

- Use Trochoidal Tool Paths: Implement trochoidal milling to reduce tool engagement time, minimizing heat buildup and tool stress.

Schlussfolgerung

Tool breakage during the machining of titanium alloy impellers is a multifaceted issue driven by the material’s low thermal conductivity, high strength, chemical reactivity, and tendency to work harden, combined with the complex geometry of impellers and suboptimal machining conditions. By understanding these factors and implementing strategies such as optimized cutting parameters, high-pressure coolant, appropriate tool selection, and rigid machine setups, manufacturers can significantly reduce tool breakage. These measures ensure improved tool life, machining efficiency, and component quality, making the process more reliable for producing high-performance titanium alloy impellers.