Welcome to KesuGroup

Precise Custom Machining, From Prototyping To Production

Kesu specializes in CNC machining and precision manufacturing of various components. We excel in prototyping and are committed to delivering reliable services to manufacturing enterprises.

- Unique Materials

- Part Produced

Rapid Prototype

Custom Machining

Tiral Production

Trusted by Professionals Worldwide

- Satisfied Client

About Kesu

Your Partner in Manchining

We help businesses bring concepts to life through reliable accurate and innovative machining and prototyping services.

Our Vision

To become a global leader in precision machining by transforming ideas into reality through advanced technology exceptional precision and machining industry focused solutions that inspire progress.

Our Mission

We empower creators engineers and businesses by providing reliable high quality custom machining and prototyping services that drive innovation efficiency and excellence across every sector we serve.

" We Turning imagination into reality through precision and innovation. "

James Tang - Founder & CEO

What We Offer

Scalable Services for Any Project

Whether one model or mass production we provide consistent quality timelines and support for projects of all sizes and scopes.

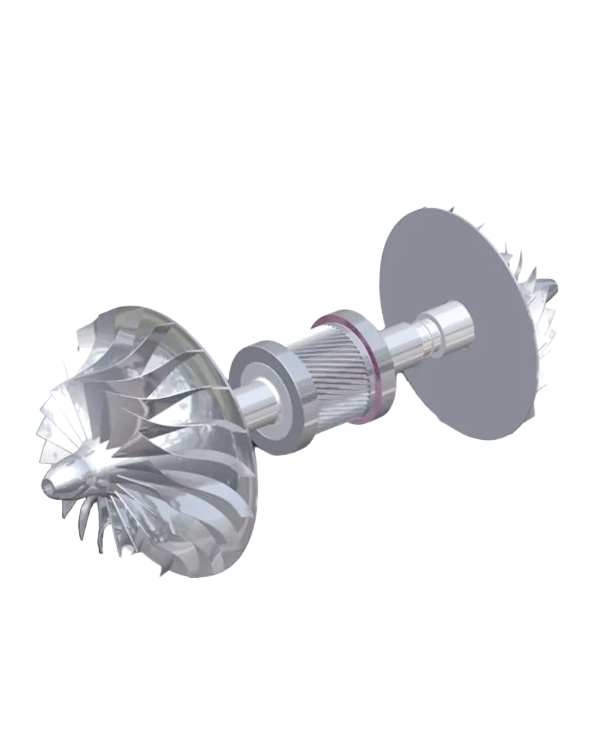

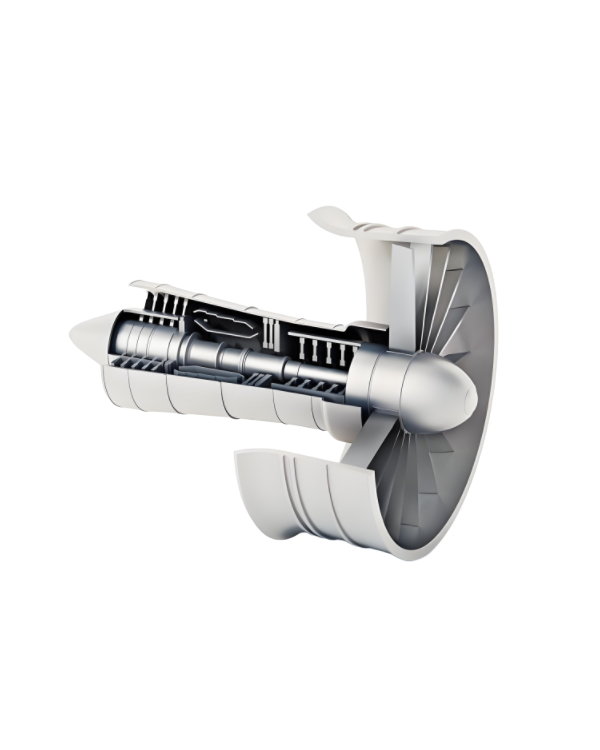

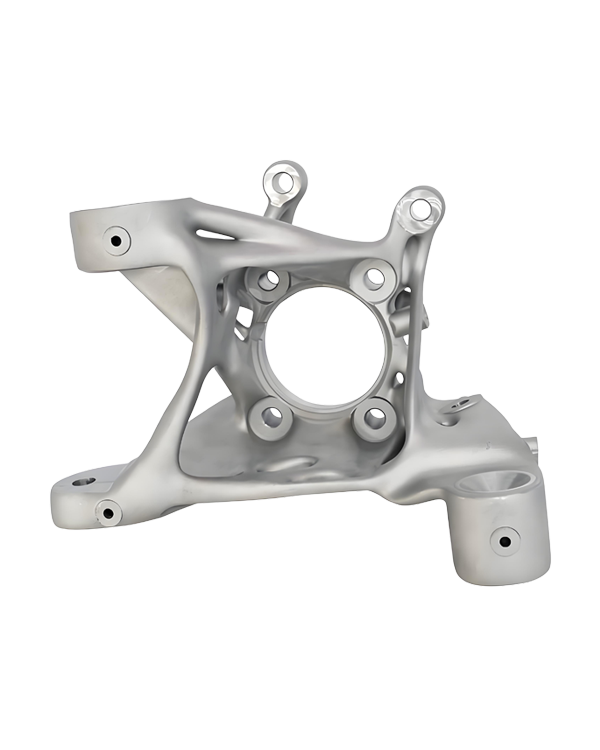

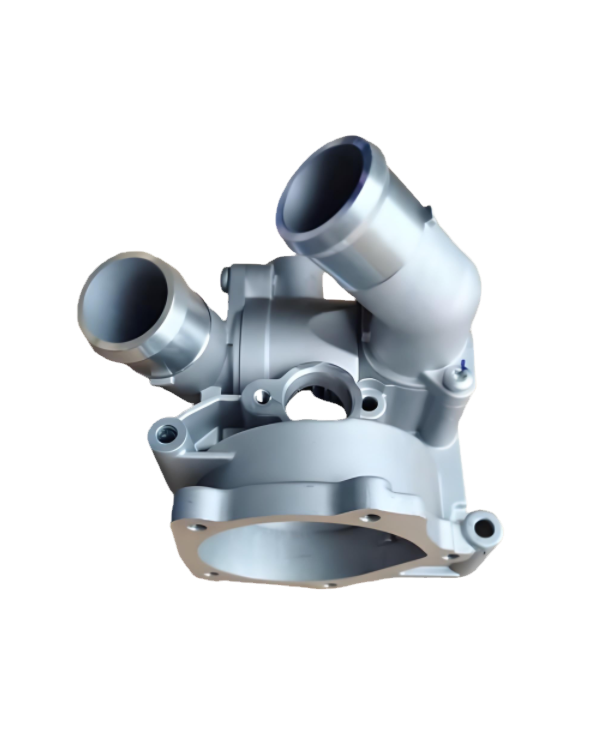

CNC Machining

Precision cutting and shaping for metal or plastic parts with consistent quality speed and tight tolerances.

3D Printing

High quality prints with precision speed and strength for prototypes models and production ready parts.

Casting & Molding

Custom molds & castings replicate complex shapes with durability and excellent surface finish.

Surface Finishing

Get your metal and plastic parts CNC machined with high quality and aesthetic surface finish.

Explore Smarter Solutions That Drive Results

Trusted By

Start Your Custom Project

with Us Now

Our team delivers tailored machining solutions with fast turnaround professional results and dependable service for every industry and application.

Testimonials

Proven Results Backed by Real Feedback

We take pride in consistently exceeding expectations with expert support reliable service and high performance machining solutions every time.

It is my pleaseure to introduce other companies to yours as your work was excellent on the heatsinks we received from you earlier this year, and your craftsmanship speaks for itself. Keep up the good work.

I would like to introduce Tony from Kesu Hardware Group. He is my long term supplier with all my trust. Can we please proceed the order for parts as quoted? Drawings and quote attached.

Alfie is the Technical Director whom I have know for many years and is currently seeking a low cost, out-sourced, component manufacturing resource with short delivery times and high quality standards.

Our Projects

Built with Accuracy and Expertise Combined

Each project demonstrates our commitment to craftsmanship innovation and delivering custom machining solutions that meet real world technical standards.

Explore projects that began as ideas.

FAQ

Quick Help for Every Machining Question

We accept Image, PDF, ZIP, STL, OBJ, STEP, and IGES files. If you are unsure which file format is best for your project, our team can help convert or optimize your file. We also provide basic design checking to ensure your file is printable and meets our quality and tolerance standards.

We offer a wide range of materials including Aluminum, Brass, Bronze, Cast Iron, Copper, Invar, Kovar, Magnesium, Stainless Steel, Steel, Titanium, Tool Steel, Zinc, PLA, ABS, PETG, Nylon, TPU, and resin-based options. Each material has different strengths, flexibility, and surface finish. Depending on your project requirements—such as durability, temperature resistance, or aesthetics. We can help you choose the most suitable material.

Our machines offer high precision with tolerances as tight as ±0.001 mm depending on material and design complexity. For parts that require engineering-level accuracy, we also offer custom machining and post-processing services. We ensure every print meets the technical and functional expectations of your project.

In most occasion, we do not provide drawing design service. Customer is responsible for submitting 2D and 3D CAD drawings, and we can provide a 2D/3D drawing for Manufacturing review upon receiving your order.

However, there is an exception. We could provide reverse design for the embossing roller of face mask machine, when the order is confirmed. Of course, it’s at the precondition that the design will never infringe the copy right.

Yes — Kesu Hardware Group has more than 80 sets of CNC machining from 3 axis to 5 axis at OUR OWN FACILITIES and in total more than 200 machines for 3D Printing, Vacuum Casting, Sheet Metal machines and injection molding machines that belong to Kesu Hardware Group. This gives us a much higher level of production control in comparison to companies that outsource machining.You just get the price from the first manufacturer directly.

No, we do not require a minimum order. Whether you need one prototype or a hundred production units, we provide the same level of attention and quality. Our goal is to support projects of all sizes, from individual creators to large-scale businesses.

Yes, we ship both locally and internationally. All parts are carefully packaged to protect against damage during transit. Shipping options and estimated delivery times will be provided when your order is confirmed. We also offer pickup for local clients if preferred.

Still Don't Have an Answer? Wanna Talk?

Our team is ready to assist you with expert support and quick answers for any challenge you are facing today.