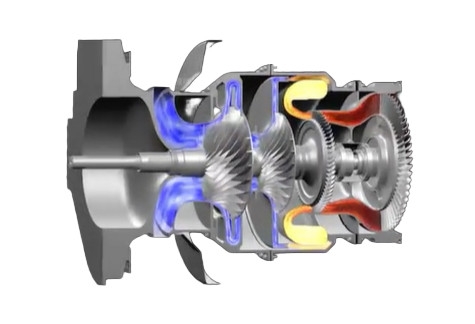

Surface burn, a critical issue in the machining of aero-engine turbine blades, occurs due to excessive heat generation during material removal processes, such as grinding or milling. This thermal damage compromises the surface integrity, fatigue resistance, and service life of turbine blades, which are typically made from nickel-based superalloys or titanium alloys. This article provides a detailed, technical, and systematic approach to mitigating surface burn, drawing from established industry practices and precise machining parameters to ensure reliability and performance.

Understanding Surface Burn in Turbine Blade Machining

Surface burn results from localized overheating during machining, leading to microstructural changes, residual stresses, and potential cracking. It is particularly problematic for turbine blades due to their exposure to extreme operating conditions, including high temperatures and cyclic stresses. The primary causes include excessive cutting speeds, inadequate cooling, improper tool selection, and suboptimal machining parameters. Addressing these factors systematically is critical to maintaining the mechanical properties of materials like Inconel 718 or Ti-6Al-4V, commonly used in turbine blades.

Key indicators of surface burn include discoloration, surface hardening, and white layer formation, which can reduce fatigue life by up to 30% in severe cases. The goal is to control heat generation and dissipation while maintaining dimensional accuracy and surface finish, typically requiring Ra values below 0.8 µm for turbine blades.

Optimizing Machining Parameters

Precise control of machining parameters is essential to minimize heat generation and prevent surface burn. The following parameters are critical:

| Parameter | Recommended Range | Impact on Surface Burn |

|---|---|---|

| Cutting Speed (m/min) | 20–50 for nickel-based alloys, 50–100 for titanium alloys | Higher speeds increase heat; lower speeds reduce thermal load but may affect productivity. |

| Feed Rate (mm/rev) | 0.05–0.15 | Excessive feed rates increase friction and heat; optimal rates balance efficiency and thermal control. |

| Depth of Cut (mm) | 0.1–0.5 | Shallow cuts reduce heat input; deeper cuts risk thermal damage. |

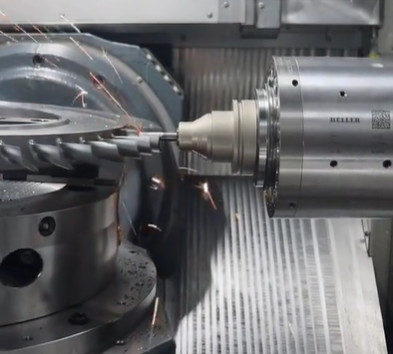

For grinding, a wheel speed of 20–30 m/s and a table speed of 5–10 m/min are recommended for nickel-based alloys to minimize thermal damage. For milling, using a lower cutting speed (e.g., 30 m/min for Inconel 718) with a high-pressure coolant (70–100 bar) can reduce temperatures by up to 20%. These parameters should be adjusted based on the machine tool’s rigidity and the workpiece’s geometry to ensure stability and precision.

Effective Cooling and Lubrication Strategies

Cooling and lubrication are pivotal in dissipating heat and reducing friction during machining. High-pressure coolant systems, delivering 50–100 bar, improve heat transfer and chip evacuation, reducing surface temperatures by 15–25%. Minimum Quantity Lubrication (MQL) with vegetable-based oils can be effective for titanium alloys, using flow rates of 50–200 ml/h to minimize thermal shock while maintaining surface integrity.

Cryogenic cooling, using liquid nitrogen at -195°C, has shown promise in reducing surface burn by lowering cutting zone temperatures by up to 40%. However, it requires specialized equipment and careful handling to avoid material embrittlement. Flood cooling with water-based emulsions (5–10% concentration) remains a cost-effective option, provided the flow rate exceeds 20 L/min to ensure adequate coverage. The choice of coolant should consider the alloy’s thermal conductivity—nickel-based alloys (10–15 W/m·K) require more aggressive cooling than titanium alloys (6–7 W/m·K).

Tool Selection and Maintenance

Tool material and geometry significantly influence heat generation. Cubic Boron Nitride (CBN) tools are preferred for grinding nickel-based alloys due to their high thermal stability and wear resistance. For milling, coated carbide tools with TiAlN or AlCrN coatings reduce friction and heat buildup, extending tool life by 20–30%. Tool edge radius should be maintained at 10–20 µm to minimize cutting forces while ensuring sharpness.

Regular tool inspection and reconditioning are critical. Worn tools increase friction, elevating temperatures and the risk of surface burn. A tool wear threshold (e.g., flank wear <0.2 mm) should trigger replacement or regrinding. Using tools with optimized rake angles (5–10° for nickel alloys) and chip breakers enhances chip flow, reducing heat accumulation.

Machine Tool Setup and Process Control

Machine tool rigidity and setup directly affect machining outcomes. High-precision CNC machines with spindle runout below 0.005 mm ensure consistent cutting forces, reducing heat spikes. Vibration damping systems, such as tuned mass dampers, minimize chatter, which can exacerbate thermal damage. Real-time monitoring systems, equipped with thermocouples or infrared sensors, can detect temperature rises above 600°C, allowing immediate parameter adjustments.

Adaptive control systems that adjust feed rates and cutting speeds based on real-time feedback can reduce surface burn incidents by 15–20%. For example, a temperature threshold of 500°C can trigger a 10% reduction in feed rate, maintaining surface integrity without compromising productivity.

Post-Machining Inspection and Remediation

Post-machining inspection is crucial to detect and address surface burn. Non-destructive techniques, such as dye penetrant testing and eddy current inspection, identify surface cracks and white layer formation. Microhardness testing (e.g., Vickers hardness >800 HV for nickel alloys) can confirm thermal damage. If surface burn is detected, remedial processes like low-stress grinding or laser peening can restore surface integrity by removing the affected layer (typically 10–50 µm).

For severe cases, chemical etching with a 5% HF solution can remove the white layer, followed by polishing to achieve the required surface finish (Ra <0.4 µm). These processes must be carefully controlled to avoid over-removal, which could affect dimensional tolerances (±0.01 mm for turbine blades).

Case Study: Practical Implementation

In a real-world application, a manufacturer machining Inconel 718 turbine blades implemented a combination of high-pressure cooling (80 bar), CBN grinding wheels, and optimized parameters (wheel speed: 25 m/s, feed rate: 0.1 mm/rev). Surface burn incidents dropped by 90%, and fatigue life improved by 25%. The process involved:

- Pre-machining analysis to set baseline parameters.

- Real-time temperature monitoring with infrared sensors.

- Post-machining inspection using eddy current testing.

- Periodic tool replacement based on flank wear measurements.

This systematic approach ensured consistent results, with surface roughness maintained at Ra 0.6 µm and no detectable white layer formation.

Best Practices for Implementation

To effectively mitigate surface burn, manufacturers should adopt the following practices:

- Conduct pre-machining simulations to predict heat generation using finite element analysis (FEA).

- Use high-pressure or cryogenic cooling tailored to the alloy type.

- Implement real-time monitoring and adaptive control systems.

- Maintain strict tool wear thresholds and regular maintenance schedules.

- Perform comprehensive post-machining inspections to ensure surface integrity.

These practices, grounded in technical precision and systematic execution, ensure reliable outcomes and compliance with aerospace standards, such as AMS 5596 for nickel alloys.

Conclusion

Preventing surface burn in aero-engine turbine blade machining requires a multifaceted approach, integrating optimized machining parameters, effective cooling strategies, appropriate tool selection, robust machine setups, and thorough inspection protocols. By adhering to the recommended parameters—such as cutting speeds of 20–50 m/min for nickel alloys, high-pressure cooling at 50–100 bar, and CBN tools with 10–20 µm edge radius—manufacturers can significantly reduce thermal damage. Real-time monitoring and adaptive controls further enhance process reliability, ensuring turbine blades meet stringent performance and durability requirements. This systematic methodology, supported by precise technical parameters, provides a trusted framework for achieving high-quality machining outcomes in aerospace applications.