Titanium machining is a critical process in industries such as aerospace, medical, and automotive due to titanium’s exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance. However, its unique properties present significant machining challenges. This guide provides a detailed overview of titanium machining, including material properties, machining types, and difficulties related to precision and complexity, with a focus on technical and systematic insights for effective processing.

Understanding Titanium and Its Machining Properties

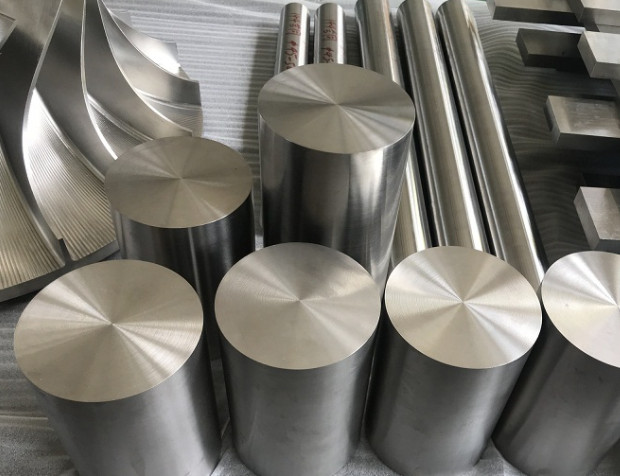

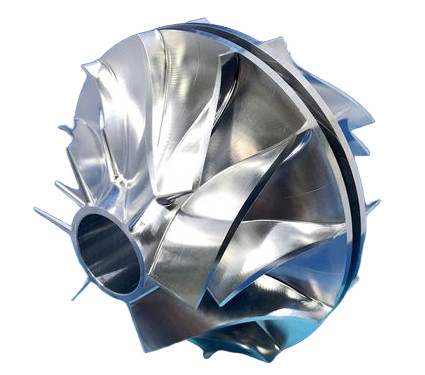

Titanium and its alloys, such as Ti-6Al-4V, are widely used for their high strength, low density, and excellent corrosion resistance. These properties make titanium ideal for applications like turbine blades, medical implants, and structural components. However, machining titanium requires careful consideration of its physical and chemical characteristics, which influence tool selection, cutting parameters, and overall process efficiency.

Titanium’s low thermal conductivity (approximately 7.2 W/m·K for Ti-6Al-4V) causes heat to concentrate at the cutting edge, leading to rapid tool wear. Its high strength requires substantial cutting forces, and its chemical reactivity at elevated temperatures can cause material adhesion to tools. Additionally, titanium’s low modulus of elasticity (around 110 GPa) results in springiness, complicating precision machining. These properties necessitate specialized tools, coolants, and techniques to achieve high-quality results.

Types of Titanium Machining Processes

Titanium machining encompasses various processes, each suited to specific applications and component geometries. Below is a detailed exploration of the primary machining types, including their applications, parameters, and considerations.

CNC Milling

CNC milling is widely used for creating complex geometries in titanium, such as slots, pockets, and contoured surfaces. It involves rotating cutting tools to remove material from a stationary workpiece. For titanium, milling requires careful management of cutting parameters to minimize heat buildup and tool wear.

Key parameters include:

- Cutting Speed: 40–60 m/min for roughing, 60–100 m/min for finishing to balance tool life and surface quality.

- Feed Rate: 0.05–0.15 mm/tooth to ensure efficient chip formation and reduce heat.

- Depth of Cut: 0.5–2 mm for roughing, 0.1–0.5 mm for finishing to control cutting forces.

- Tool Material: Carbide or coated carbide (e.g., TiAlN) for durability and heat resistance.

Trochoidal milling, which uses circular tool paths to reduce tool engagement, is effective for titanium to minimize heat and improve chip evacuation. High-pressure coolant systems (70–100 bar) are recommended to dissipate heat and prevent chip re-cutting.

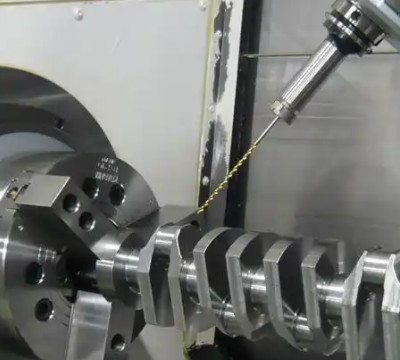

CNC Turning

CNC turning is used for cylindrical titanium components, such as shafts and rings, where the workpiece rotates while a stationary tool removes material. Titanium’s elasticity can cause deflection, requiring rigid setups and precise control of cutting parameters.

Recommended parameters include:

- Cutting Speed: 30–50 m/min to reduce thermal stress.

- Feed Rate: 0.1–0.3 mm/rev for roughing, 0.05–0.1 mm/rev for finishing.

- Depth of Cut: 1–3 mm for roughing, 0.2–0.5 mm for finishing.

- Tool Geometry: Positive rake angles (5–15°) to reduce cutting forces and improve chip flow.

Turning titanium benefits from rigid workholding and short tool overhangs to minimize vibration. High-pressure coolant is essential to manage heat and ensure surface integrity.

Drilling

Drilling creates holes in titanium components, such as those used in aerospace fasteners or medical implants. Titanium’s low thermal conductivity and tendency to produce long, stringy chips complicate drilling, requiring specialized tools and techniques.

Key parameters include:

- Cutting Speed: 20–40 m/min to control heat buildup.

- Feed Rate: 0.02–0.1 mm/rev to prevent chip clogging.

- Tool Material: Carbide drills with TiAlN or TiCN coatings for wear resistance.

- Peck Drilling: Incremental drilling (3–5 mm per peck) to clear chips and reduce heat.

Peck drilling is critical to prevent chip accumulation, which can damage tools and workpieces. High-pressure coolant or through-tool coolant delivery enhances chip evacuation and tool life.

Electrical Discharge Machining (EDM)

EDM is a non-contact process that uses electrical discharges to remove material, ideal for intricate titanium geometries where mechanical stresses must be avoided. It is commonly used for aerospace and medical components requiring high precision.

Key parameters include:

- Voltage: 10–15 V for stable discharges.

- Current: 5–20 A, adjusted based on material removal rate.

- Electrolyte: Sodium chloride (1 lb/gal) for titanium machining.

- Electrode Feed Rate: 0.2–0.5 µm/s for precise material removal.

EDM avoids mechanical stresses, making it suitable for thin-walled or complex titanium parts. However, it is slower than conventional machining, so it is typically used for finishing or small-batch production.

Waterjet Cutting

Waterjet cutting uses a high-pressure abrasive water stream to cut titanium, minimizing thermal distortion. It is ideal for roughing out shapes or preforms before precision machining.

Key parameters include:

- Pressure: 50,000–60,000 psi for efficient cutting.

- Abrasive Flow Rate: 0.5–1 lb/min for consistent material removal.

- Cutting Speed: 50–150 mm/min, depending on thickness.

Waterjet cutting is thermally neutral, preserving titanium’s material properties, but it may require secondary machining for tight tolerances.

Materials and Prototyping in Titanium Machining

Titanium machining involves various grades and alloys, each with specific properties affecting machinability. Prototyping is a critical step to validate designs and machining strategies before full-scale production.

Titanium Grades and Alloys

Titanium is available in commercially pure grades (Grades 1–4) and alloys, with Ti-6Al-4V (Grade 5) being the most common due to its balanced strength and machinability. The table below summarizes key titanium materials and their machining characteristics:

| Material | Composition | Applications | Machining Characteristics |

|---|---|---|---|

| Commercially Pure Titanium (Grade 2) | 99% Ti, O, N | Medical implants, marine components | Easiest to machine, lower strength, less tool wear |

| Ti-6Al-4V (Grade 5) | 6% Al, 4% V | Aerospace, biomedical | High strength, low thermal conductivity, prone to galling |

| Ti-10V-2Fe-3Al | 10% V, 2% Fe, 3% Al | High-strength aerospace parts | Difficult to machine, high cutting forces, rapid tool wear |

Prototyping Considerations

Prototyping titanium components allows manufacturers to test designs, optimize tool paths, and refine cutting parameters. CNC machining is commonly used for prototyping due to its precision and flexibility. Key considerations include:

- Material Selection: Use the same titanium grade as the final product to ensure consistent machinability.

- Tool Path Optimization: Employ CAD/CAM software (e.g., Mastercam) to simulate tool paths and minimize heat generation.

- Fixture Design: Rigid fixtures to prevent workpiece deflection, especially for thin-walled parts.

- Iterative Testing: Produce multiple prototypes to adjust speeds, feeds, and coolant strategies for optimal results.

Prototyping reduces risks in full-scale production by identifying potential issues, such as tool wear or dimensional inaccuracies, early in the process.

Difficulties in Titanium Machining

Machining titanium presents several difficulties due to its material properties, impacting precision, complexity, and overall process efficiency. Below are the primary challenges and strategies to address them.

Heat Buildup and Tool Wear

Titanium’s low thermal conductivity causes heat to concentrate at the cutting edge, accelerating tool wear and potentially causing tool failure. This issue is compounded by titanium’s chemical reactivity, which leads to galling and material adhesion to tools.

Solutions:

- Use high-pressure coolant systems (70–100 bar) to dissipate heat.

- Employ carbide or coated carbide tools with TiAlN or TiCN coatings for thermal resistance.

- Reduce cutting speeds (30–60 m/min) to minimize heat generation.

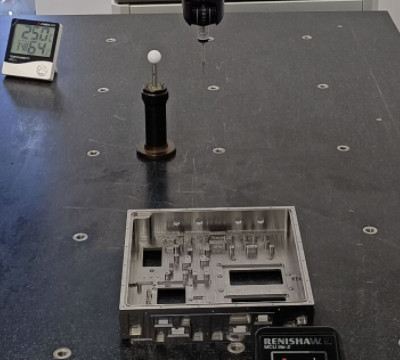

Precision and Dimensional Accuracy

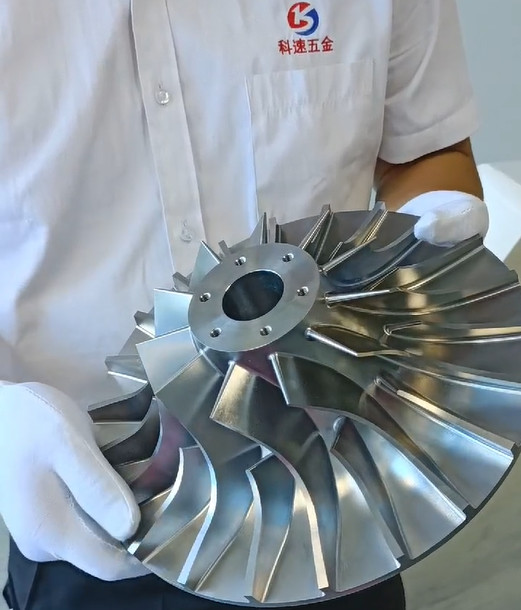

Titanium’s low modulus of elasticity causes springback, making it difficult to maintain tight tolerances (e.g., ±0.001”). Complex geometries, such as turbine blades, impellers, further complicate precision due to tool deflection and vibration.

Solutions:

- Use rigid machine setups and damped tool holders to minimize vibration.

- Implement 5-axis CNC machining for complex geometries to ensure consistent tool engagement.

- Employ precision metrology tools (e.g., CMM) to verify dimensional accuracy.

Complexity of Chip Management

Titanium produces long, stringy chips that can clog tools and damage workpieces. Poor chip evacuation increases the risk of surface defects and tool breakage.

Solutions:

- Use peck drilling or trochoidal milling to improve chip evacuation.

- Apply through-tool coolant to flush chips from the cutting zone.

- Optimize tool geometry with chip breakers to produce shorter, manageable chips.

High Cutting Forces and Work Hardening

Titanium’s high strength requires significant cutting forces, which can cause tool deflection and work hardening. Work hardening occurs when improper cutting techniques increase surface hardness, making subsequent passes more difficult.

Solutions:

- Use high feed rates (0.1–0.3 mm/rev) to create thicker chips and reduce rubbing.

- Maintain continuous tool motion to prevent work hardening.

- Select tools with positive rake angles to reduce cutting forces.

Best Practices for Titanium Machining

To achieve optimal results in titanium machining, manufacturers should adopt the following best practices:

| Practice | Description | Benefit |

|---|---|---|

| Tool Selection | Use carbide or coated carbide tools with TiAlN or TiCN coatings. | Enhanced tool life and reduced galling. |

| Coolant Strategy | Implement high-pressure coolant (70–100 bar) or through-tool cooling. | Improved heat dissipation and chip evacuation. |

| Cutting Parameters | Optimize speeds (30–60 m/min) and feeds (0.05–0.15 mm/tooth). | Balanced tool life and surface quality. |

| Machine Rigidity | Use rigid setups and damped tool holders. | Reduced vibration and improved precision. |

These practices, combined with proper material selection and prototyping, ensure efficient and high-quality titanium machining.

Kesu Titanium Machining: Mastering Toughness, Defining Precision

Kesu transforms titanium's unique challenges—low thermal conductivity, high strength, and reactivity—into engineering triumphs. Specializing in CNC milling, turning, EDM, and waterjet cutting for alloys like Ti-6Al-4V, we deploy carbide-coated tools, high-pressure coolant systems (70–100 bar), and advanced toolpaths to conquer heat buildup, chip management, and precision demands. From aerospace turbine blades to medical implants, our expertise turns titanium's toughness into components that redefine performance and reliability. Choose Kesu CNC company: where titanium meets its perfect match in machining excellence.

Conclusion

Titanium machining is a complex but manageable process when approached with the right techniques and tools. Understanding titanium’s material properties, selecting appropriate machining types, and addressing difficulties such as heat buildup, precision, and chip management are critical for success. By optimizing cutting parameters, using advanced tools, and implementing robust prototyping strategies, manufacturers can achieve high-quality titanium components for demanding applications in aerospace, medical, and other industries.

Frequently Asked Questions (FAQs) About Titanium Machining

What types of titanium materials are commonly machined?

Titanium machining typically involves commercially pure titanium (Grades 1–4) and alloys, with Ti-6Al-4V (Grade 5) being the most widely used due to its balanced strength and machinability. Other common alloys include Ti-10V-2Fe-3Al (for high-strength aerospace parts) and Grade 2 (commercially pure, easier to machine). Each material has unique properties—e.g., pure titanium is softer but less heat-resistant, while alloys like Ti-6Al-4V offer high strength but require more specialized machining.

What are the main challenges in machining titanium?

Heat buildup: Low thermal conductivity (≈7.2 W/m·K for Ti-6Al-4V) traps heat at the cutting edge, accelerating tool wear.

Chemical reactivity: At high temperatures, titanium can adhere to tools (galling), causing damage.

Springiness: Low modulus of elasticity (≈110 GPa) leads to deflection, complicating precision.

Chip management: Titanium produces long, stringy chips that can clog tools or scratch workpieces.

What processes are used for complex or high-precision titanium parts?

EDM (Electrical Discharge Machining): Ideal for intricate geometries (e.g., medical implants) as it avoids mechanical stress.

5-axis CNC machining: Enables precise cutting of complex shapes (e.g., turbine blades) by adjusting tool angles dynamically.

Waterjet cutting: Used for roughing or heat-sensitive parts, as it avoids thermal distortion.

How can precision and dimensional accuracy be ensured?

Rigid setups: Sturdy fixtures and damped tool holders reduce vibration and deflection.

Iterative prototyping: Testing tool paths and parameters with prototypes (using the same titanium grade) helps refine processes.

Metrology tools: Coordinate Measuring Machines (CMMs) verify tolerances (often as tight as ±0.001”).

What industries rely on titanium machining?

Aerospace (turbine blades, structural components), medical (implants, surgical tools), automotive (high-performance parts), and marine (corrosion-resistant components) are the primary sectors, leveraging titanium’s strength-to-weight ratio, corrosion resistance, and high-temperature performance.